Leaks on the suction side of the hydraulic system are

more difcult to nd and more serious since air or dirt

introduced into the system causes rapid component

wear and eventual failure. Some symptoms of suction

leakage are:

• Hydraulic uid “foaming.”

• Sluggish system operation.

• Unusual noises in the hydraulic pumps or motors.

Checking Hydraulic Oil Level

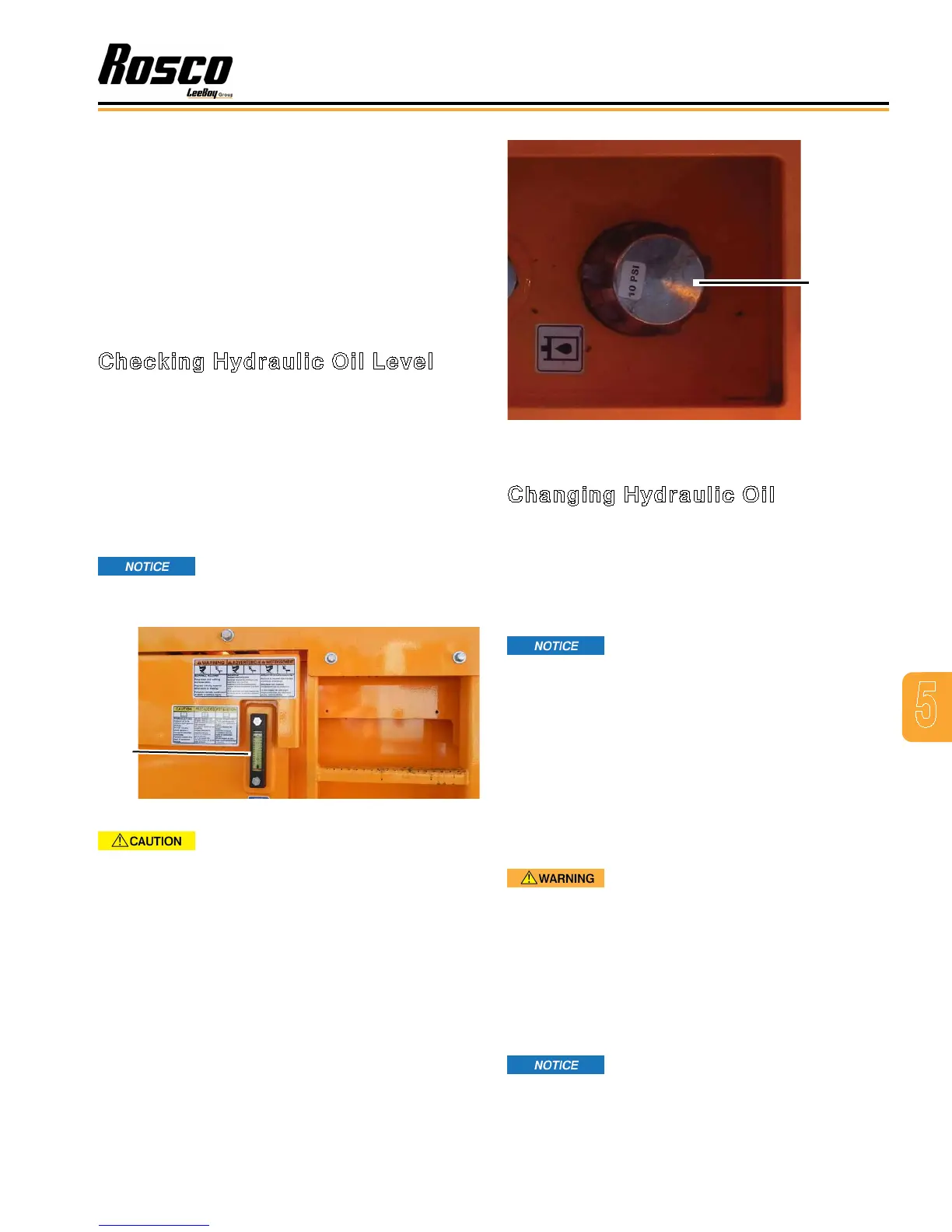

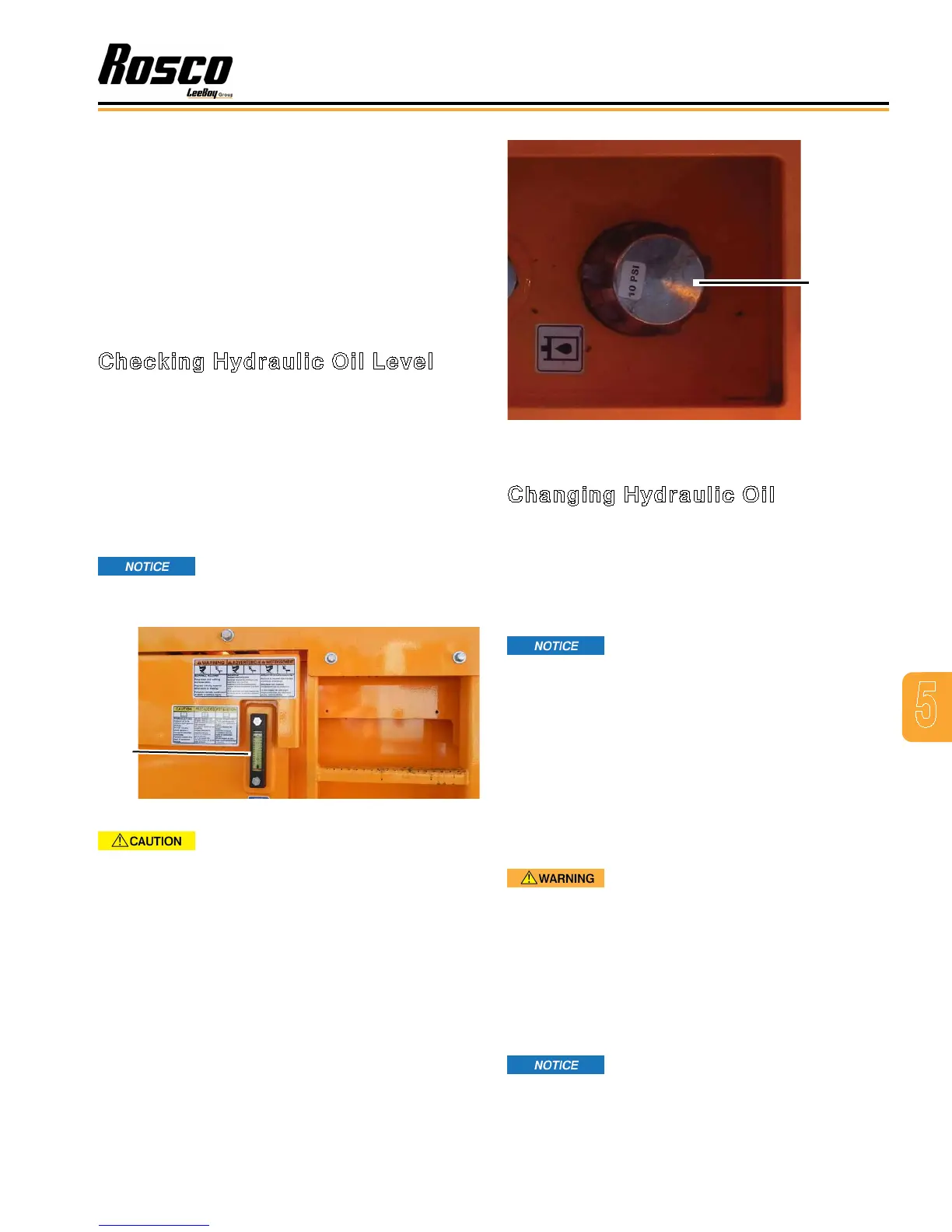

The hydraulic oil tank and sight gauge is located on the

right side of the machine. (Figure 5-26) The hydraulic

oil ll cap is just behind the left operator platform.

(Figure 5-27)

1. Make sure that the hoppers are retracted so that oil

ows to the tank, ensuring an accurate reading.

2. Wait 10 minutes after engine has been shut down

before checking hydraulic oil.

Oil level is determined by sight gauge.

Hydraulic oil should be added if the oil level falls

below the ll line. Never ll above the black ll line.

Figure 5-26. Hydraulic Gauge

Use extreme caution when removing

the ller cap to prevent foreign matter from entering

the hydraulic tank.

3. If level is low, clean around the hydraulic oil ller cap

before removing to add hydraulic oil to the tank.

4. Fill tank to the black ll line on sight gauge.

5. Screw the hydraulic oil ller cap back onto the

hydraulic tank.

Hydraulic

Fluid

Fill Cap

Figure 5-27. Hydraulic Oil Fill Cap

Changing Hydraulic Oil

Changing the hydraulic oil removes the accumulation

of dirt, water and mechanical wear particles from the

hydraulic oil reservoir and system. The chemical

structure of hydraulic oil changes after continuous

use, therefore, new oil is important to ensure correct

operation of the hydraulic system.

Hydraulic oil that has oxidized or

contains contamination can shorten the expected

service life of the components in the hydraulic

system.

Use the following procedures to change the hydraulic

oil:

1. Stop the engine. Allow the hydraulic oil to cool

until it is at a warm temperature. Slowly loosen and

remove the hydraulic oil reservoir ller cap. Put a

clean, lint-free cloth over the hydraulic tank ll cap

opening and secure in place with tape.

DO NOT drain the hydraulic oil from

the reservoir when it is HOT. Hot hydraulic oil can

cause serious injury. Drain at a warm temperature

only.

2. Carefully remove the plug from the hydraulic

tank. Use a drain collection container of sufcient

capacity to collect the hydraulic oil underneath.

Allow all of the hydraulic oil to drain into the

container.

DO NOT ll the hydraulic oil reservoir

with new hydraulic oil until the suction strainer has

been serviced.

5

Maintenance

Rosco CSV Variable Width Chip Spreader 5-21

Loading...

Loading...