BRP-Rotax

Maintenance Manual

72-00-00

page 32

May 01/2007

Effectivity 912/914 Series

Edition 1 / Rev. 0

d02622

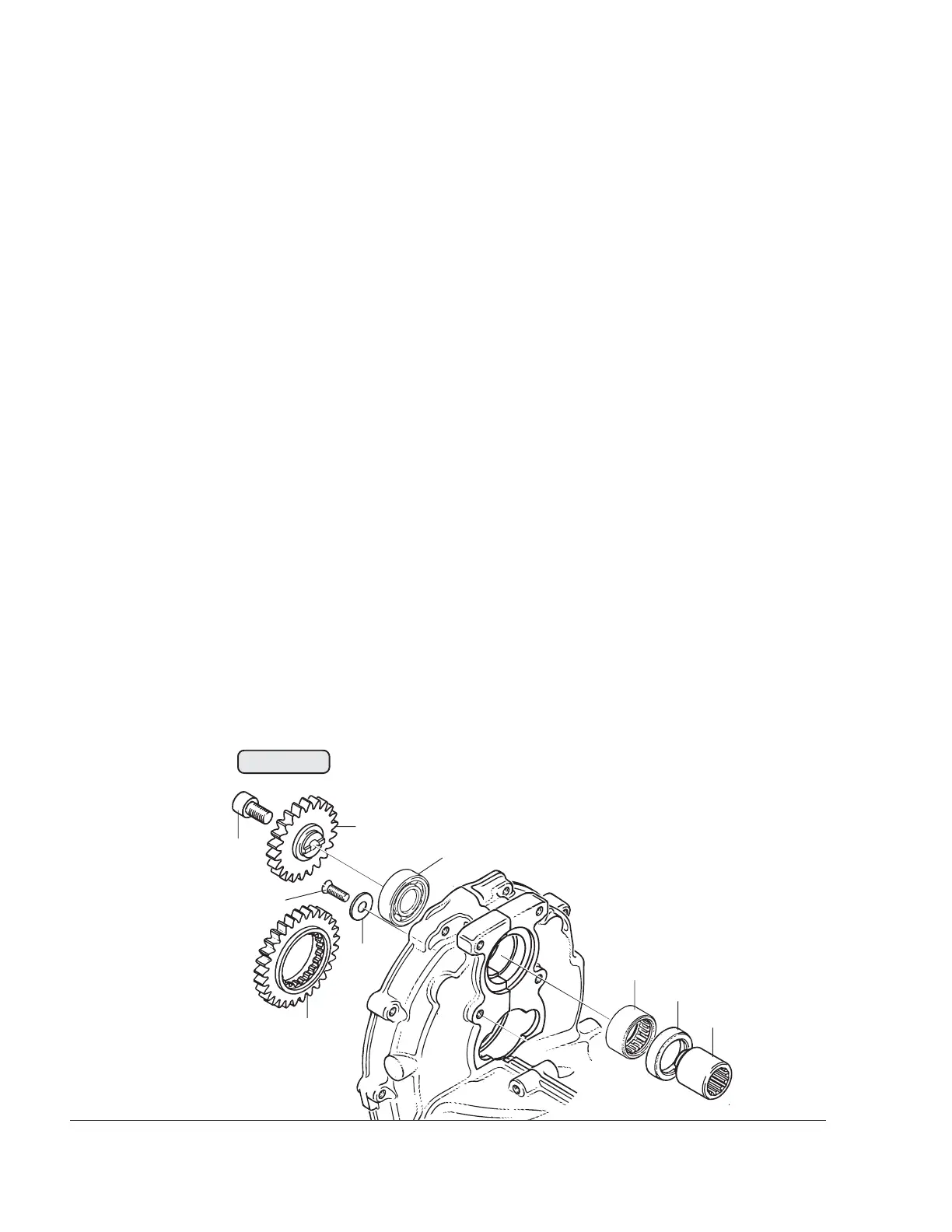

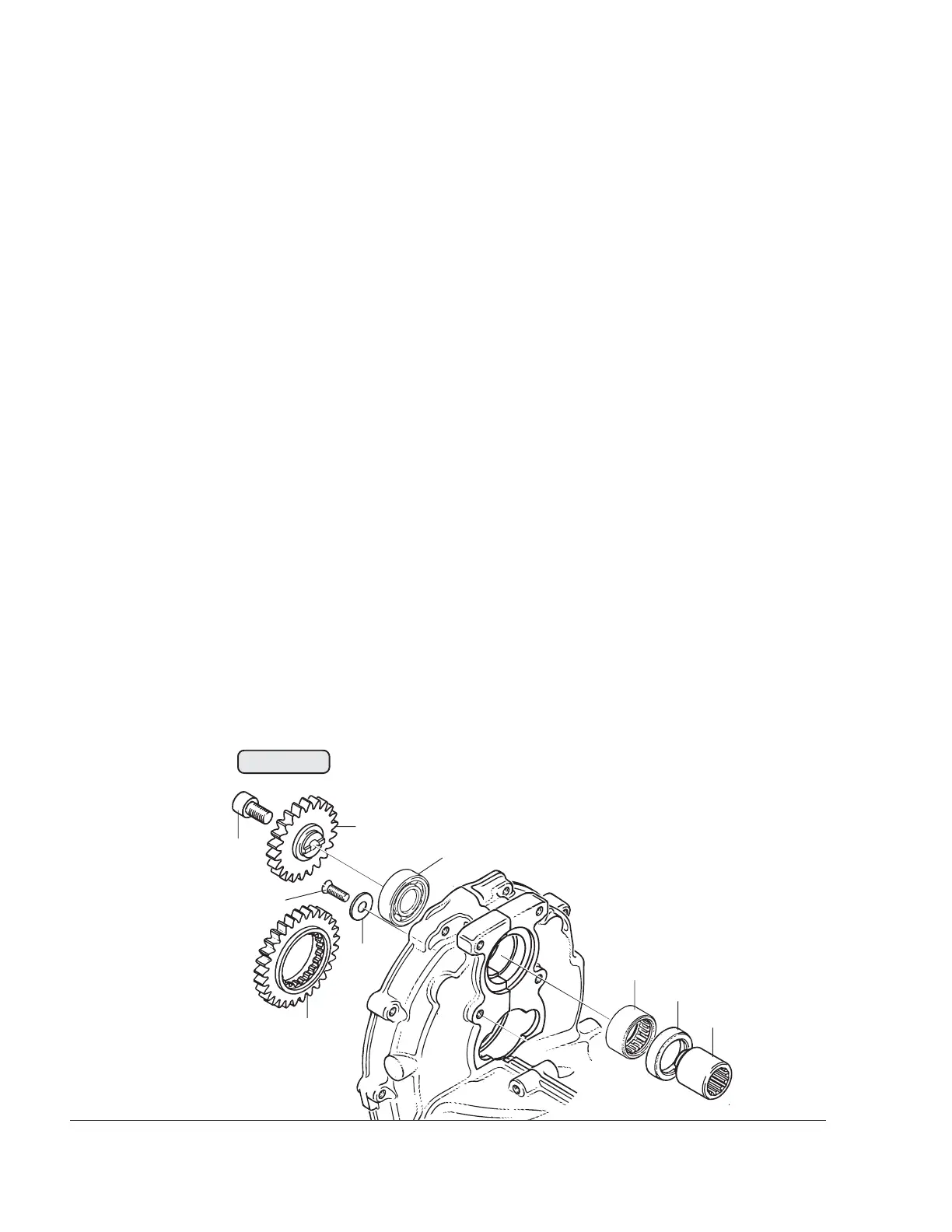

3.9.6) Vacuum pump drive removal

See Fig. 72-30.

The vacuum pump is driven via the drive gear (1) fitted on the propeller

shaft.

Check the ball bearing (2) and the needle sleeve (3). Check the gear-

tooth system of drive gear (1), the vacuum pump gear (4), the drive

sleeve (5) and the drive shaft of the vacuum pump.

If the ball bearing or needle sleeve are to be replaced, remove the

vacuum pump as follows:

Lock the drive sleeve (5) with the holder, part no. 242660, remove the

allen screw (6) M8x14 and remove the vacuum pump gear (4) with the

drive sleeve (5).

Remove the countersunk screw (7) M5x12 with the washer (8) for ball

bearing fixation.

Lift out the oil seal (9) and press out the needle sleeve and ball bearing

with a suitable step punch towards the propeller flange. Clean and

inspect bearing seat.

◆ NOTE: During this procedure, the needle sleeve (3), the oil

seal (9) and the ball bearing (2) are damaged and must

be replaced.

■ CAUTION : The attachment screw (6) M8 of the vacuum pump

gear for hydraulic governor drive is 16 mm long

(0.63 in.) and with a low screw head. For vacuum

pump drive, however, it is only 14 mm long

(0.55 in.) with standard screw head.

Fig. 72-30

00252

8

9

1

2

3

4

5

6

7

Loading...

Loading...