BRP-Rotax

Maintenance Manual

Effectivity 912/914 Series

Edition 1 / Rev. 0

72-00-00

page 39

May 01/2007

d02622

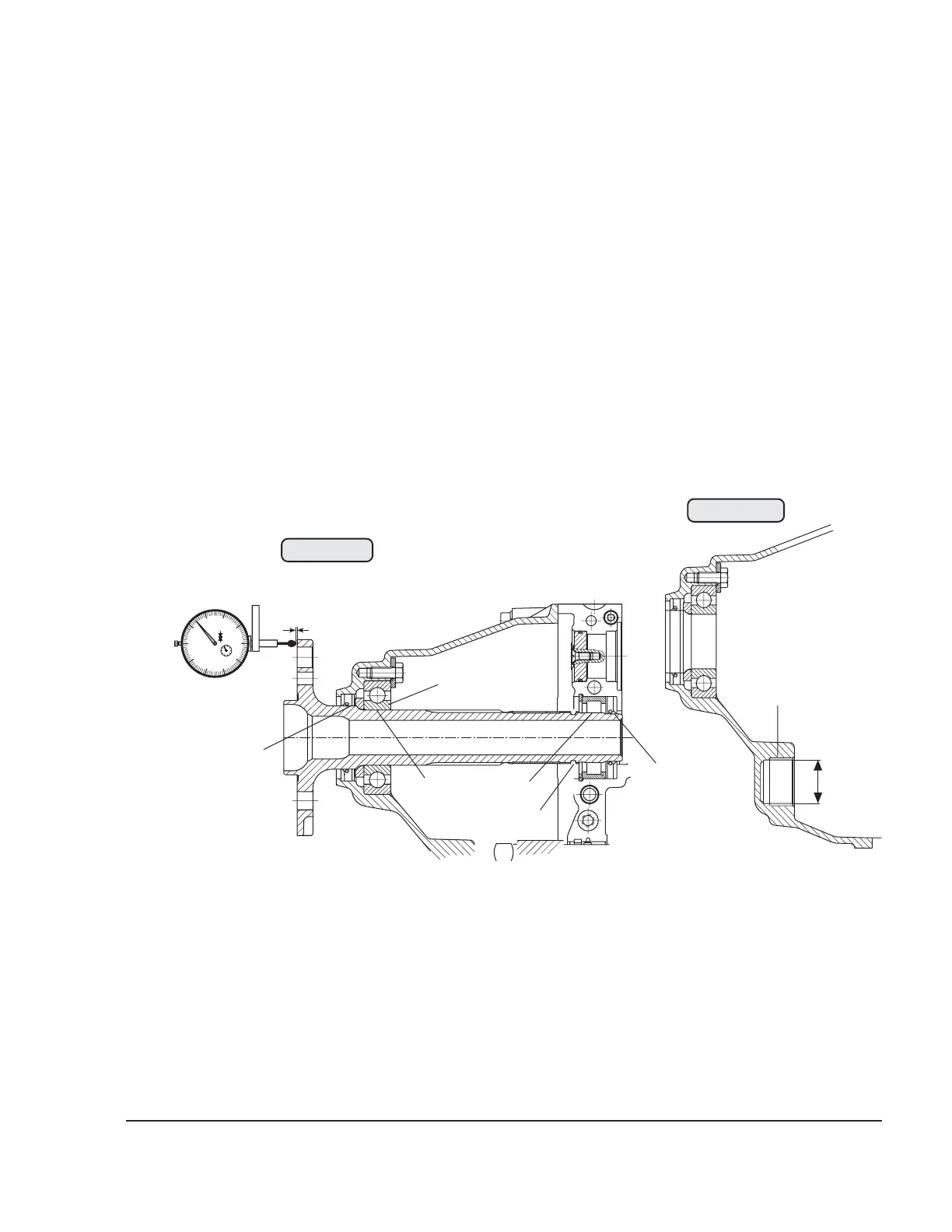

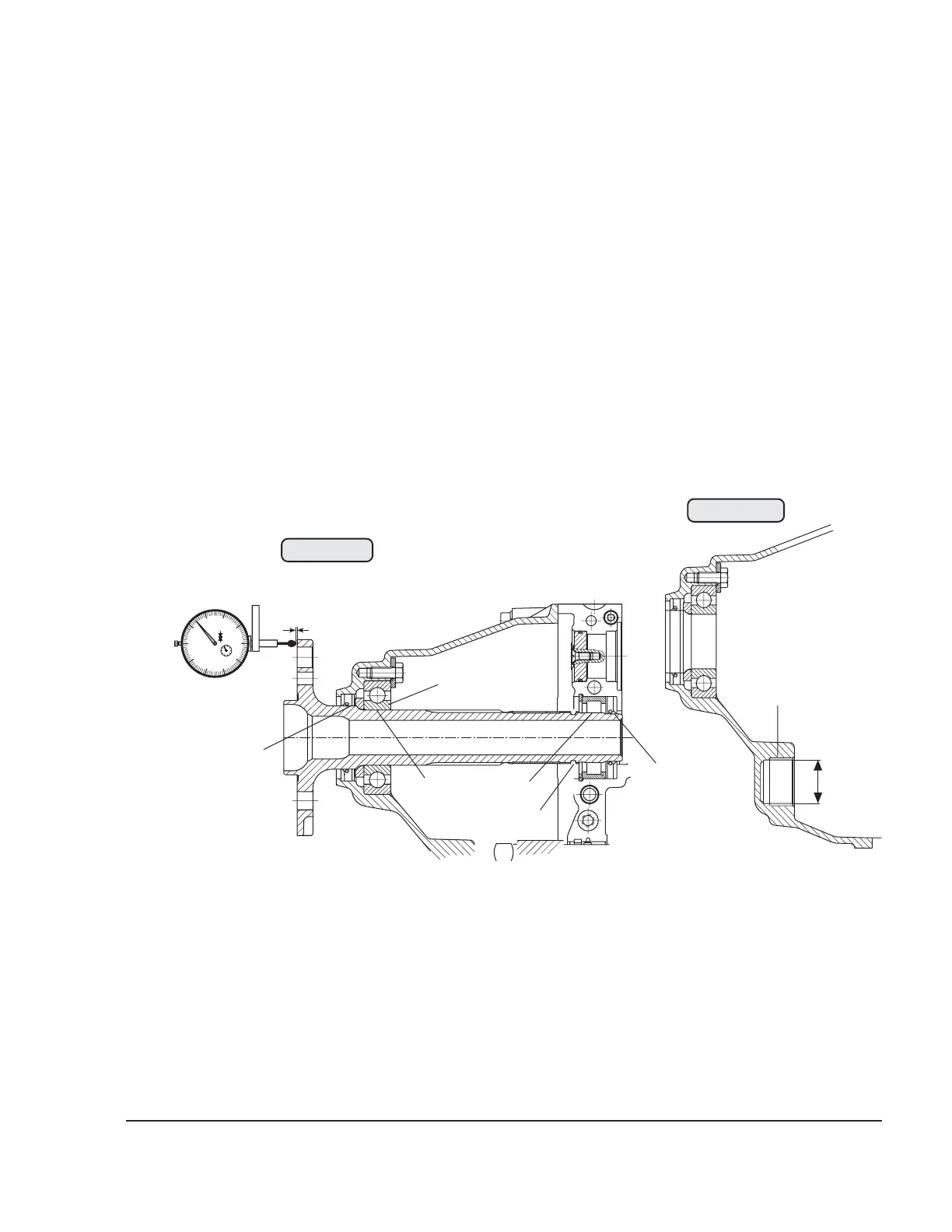

3.9.10) Gearbox components inspection

See Figs. 72-37, 72-38, 72-39, 72-40, 72-41 and 72-42.

Clean disassembled gearbox with suitable cleaning agents and check

the following parts:

— Check that the bearing bushing (1)

for crankshaft support bearing

in the gear cover fits tightly and measure dimension (GB01).

See 72-00-00 sec. 4.

— Measure both bearing seats (2) and (3) on the propeller shaft. See

dimension (GB02) and dimension (GB03). Check oil seal running

surface (4) and (5). Roll propeller shaft and check for run out. Check

the run out of the propeller flange, see dimension (GB04).

See 72-00-00 sec. 4.

■ CAUTION: The entire propeller shaft with attachment

bores must be free of corrosion, and there must

be no fretting corrosion at bearing points

((2) and (3)).

0

10

20

30

40

50

60

70

80

90

0.01mm

1

2

3

4

5

6

7

8

9

0

Maß/dim.

00266

Fig. 72-38

GB04

Fig. 72-37

1

2

3

4

5

6

7

GB04

Loading...

Loading...