73-00-00

page 60

May 01/2007

Effectivity 912/914 Series

Edition 1 / Rev. 0

d02623

BRP-Rotax

Maintenance Manual

40 mm

04730

2

03884

2

5

4

3

1

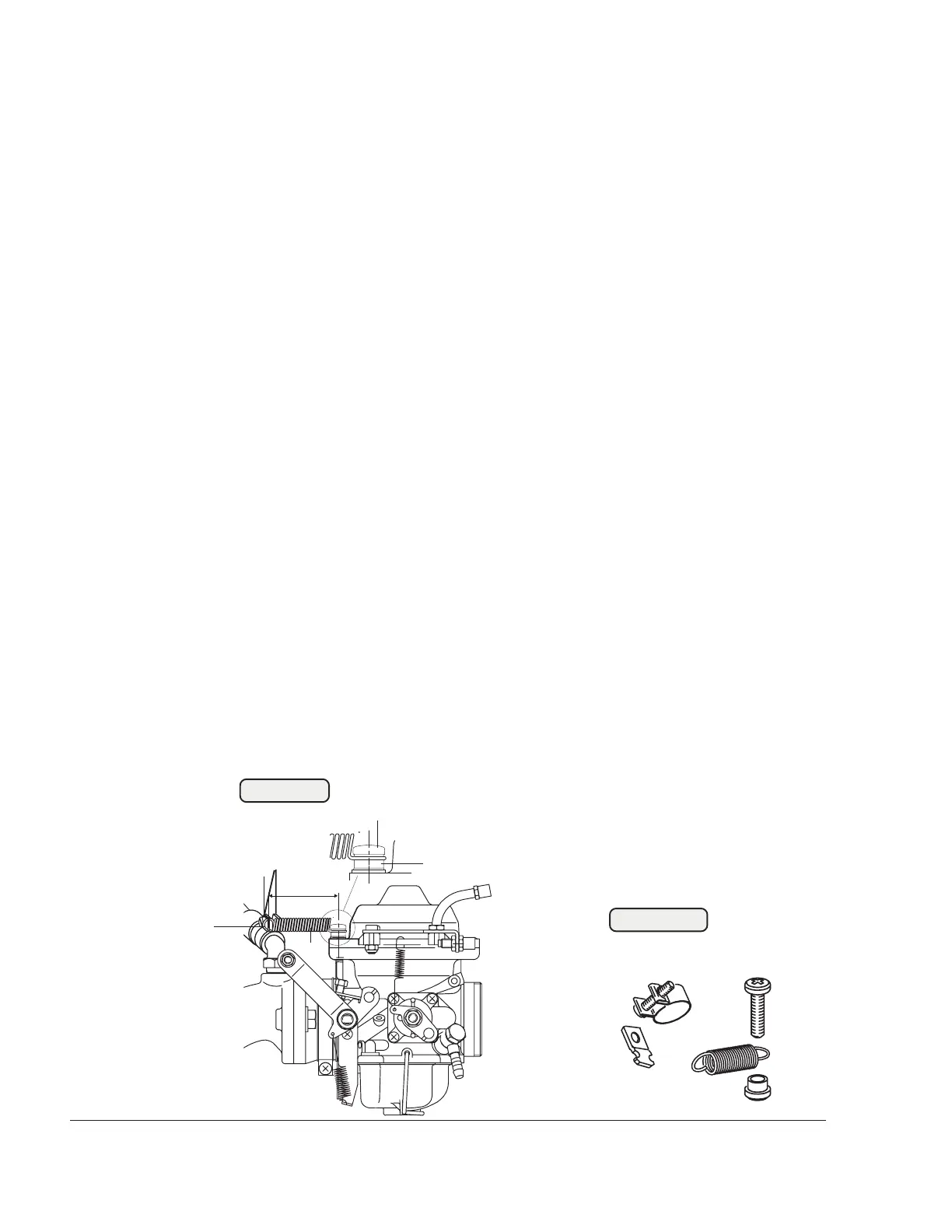

Fig. 73-53

Fig. 73-52

3.6) Intake manifolds fitting

See 72-00-00 sec. 3.17.

3.7) Engaging the carburetor support

See Figs. 73-52 and 73-53.

Check that the tension spring (1) moves freely in the allen screw (2) and in the

distance sleeve (5) and engage the tension spring in the engagement latch (3)

using a suitable tool. Ensure that the two arms (4) of the tension clamp with the

engagement latch point upwards. If necessary, correct the position of the

tension clamp.

■ CAUTION: To ensure efficient carburetor suspension, a distance of 40 mm

(1.57 in.) between the allen screw (2) and the engagement latch

(3) must be respected.

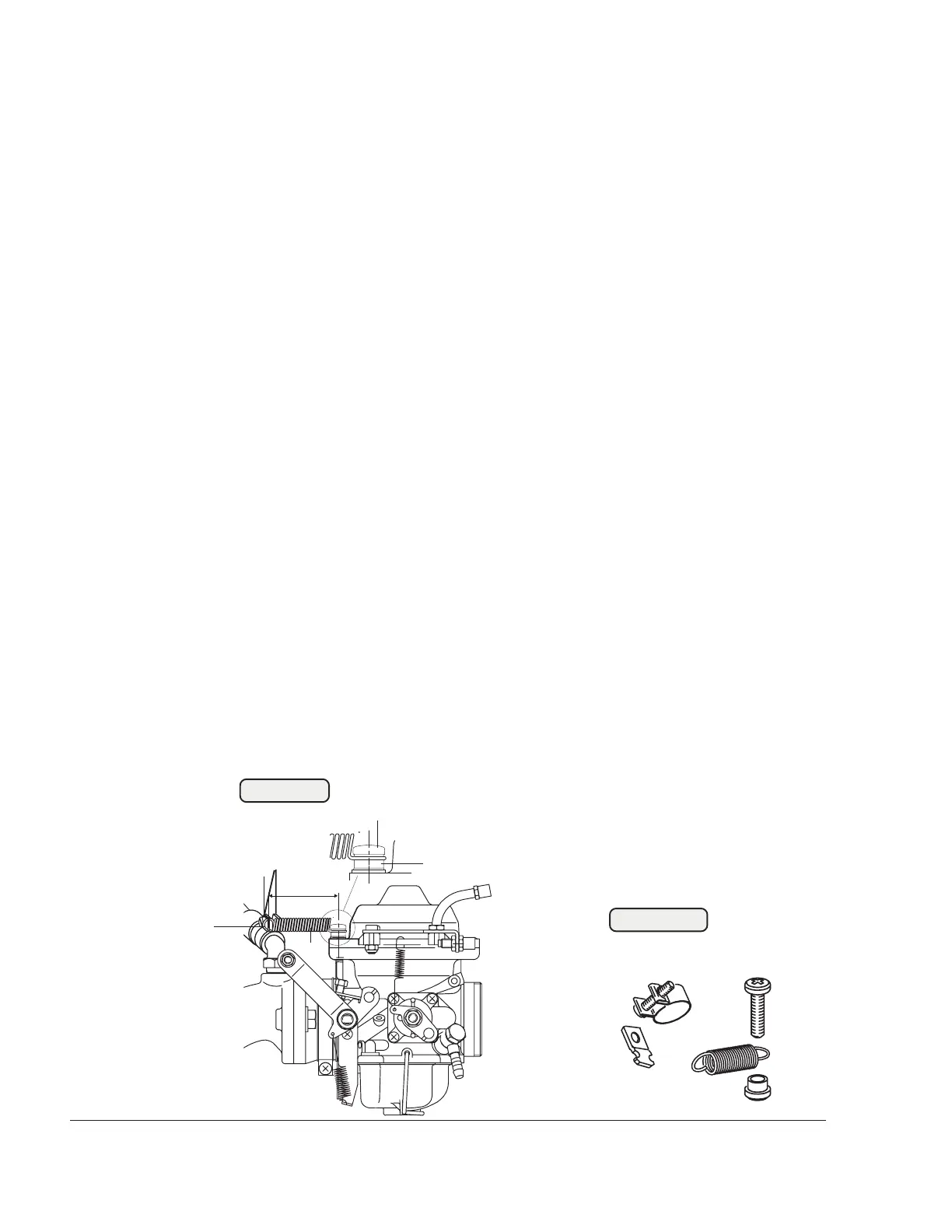

If a counter sunk screw is fitted instead of the allen screw and the distance

sleeve, support set part no. 887730, see Fig. 73-53, must be used.

Repeat procedure for second carburetor.

◆ NOTE: Only on 912 Series: On engine models from the year 96

onwards, the carburetor support is already fitted in serial

production. We recommend installing it on all engines older than

this. See Service Bulletin SB-912-010,”Fitting of a carburetor

support”, latest issue.

Engines 912 S, 912 ULS, 914 UL and 914 F have been equipped

with the carburetor support since the beginning of production.

(1.57 in.)

Loading...

Loading...