BRP-Rotax

Maintenance Manual

72-00-00

page 40

May 01/2007

Effectivity 912/914 Series

Edition 1 / Rev. 0

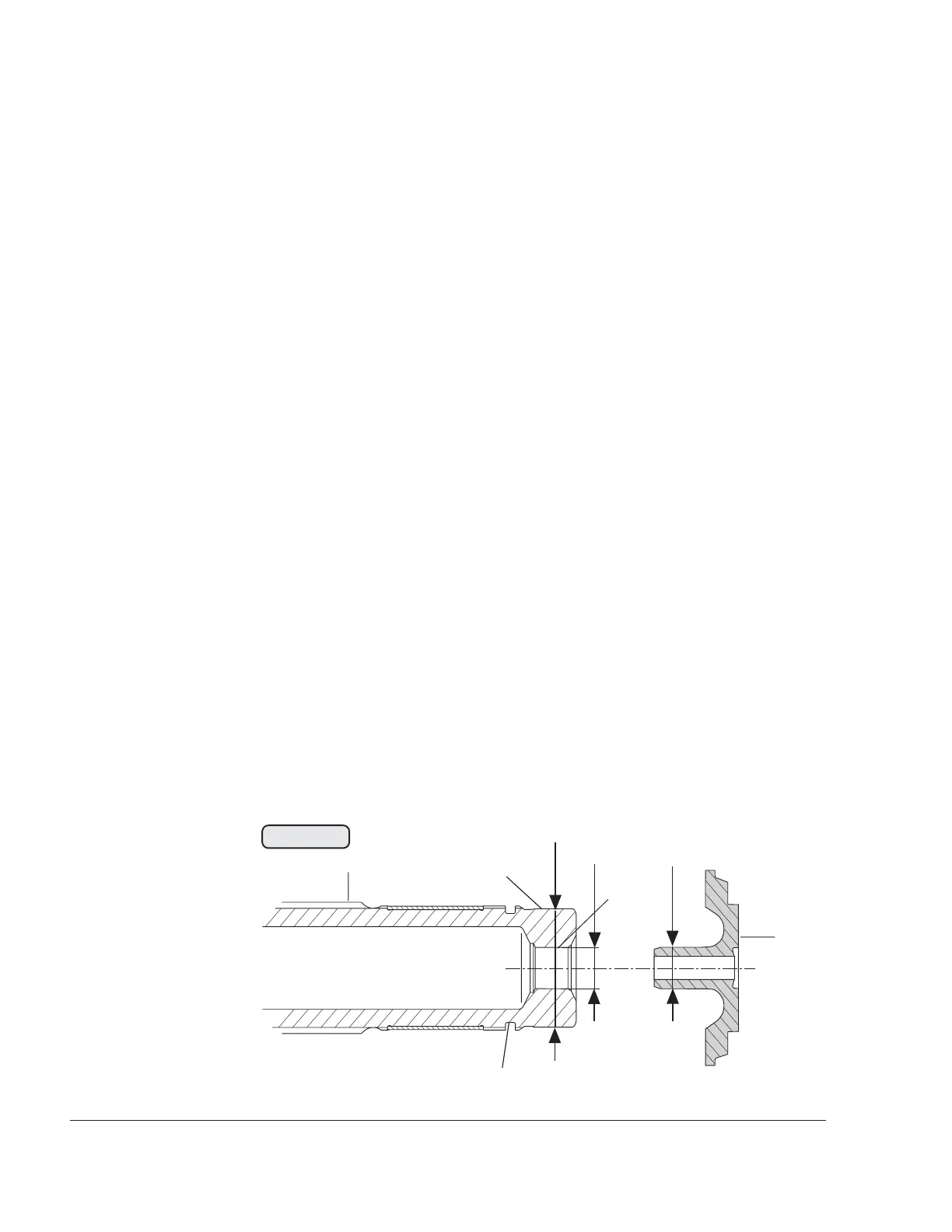

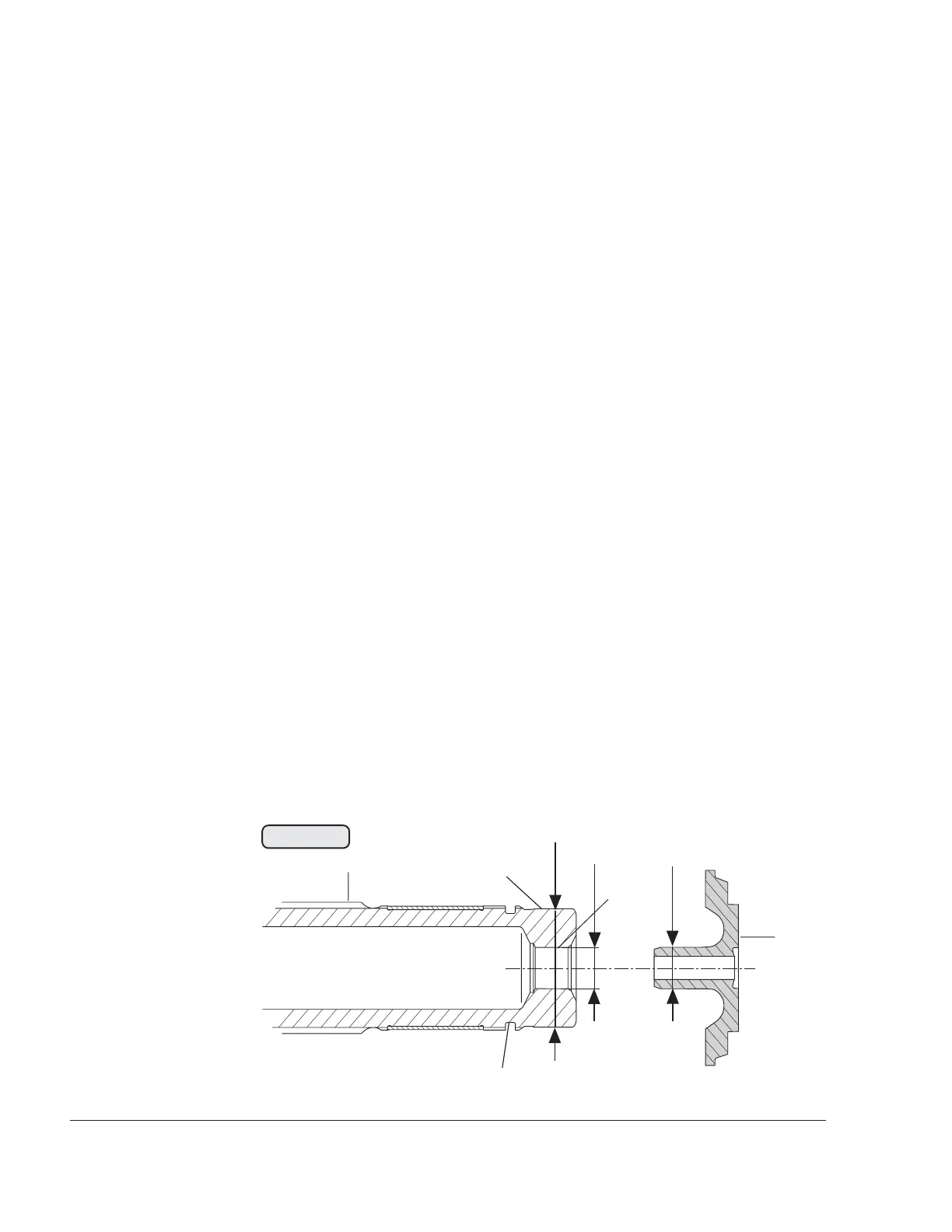

d02622

Treatment of corrosion damage and surface damage to the

propeller flange

The flange of the propeller shaft is subject to corrosion. After wrapping

the propeller shaft (2) in plastic tape or covering it with plastic tubing,

the propeller flange can be treated with an abrasive.

■ CAUTION: Before applying the protective coating, carefully cover

the flange face (3), the attachment bores and the

propeller shaft in this area (2).

To prevent corrosion damage, the back of the propeller flange should

be coated with a corrosioninhibiting agent.

Where there is greater corrosion damage and the material has been

affected, the propeller shaft must be replaced.

When carrying out any of these steps, the manufacturers instructions must

be observed.

— The ball bearing (6) must be an interference fit on its outer race in

the gearbox housing and on its inner race on the propeller shaft.

Check groove (7) for the retaining rings and the gear-tooth system

(8) for wear or damage.

On configuration 3, the inner diameter (9) of the propeller shaft must

be checked in the area of the oil inlet flange (10), dimension (GB05/

GB06). See 72-00-00 sec. 4.

Inspect the propeller shaft for cracks. See 00-00-00 sec.10.4.

Register the results of the magnetic particle inspection in the

respective form sheet. See 72-00-00 sec. 5.

GB03

GB05

GB06

Ausführung 3

1

7

07454

Fig. 72-39

8

9

10

configuration 3

Loading...

Loading...