BRP-Rotax

Maintenance Manual

72-00-00

page 56

May 01/2007

Effectivity 912/914 Series

Edition 1 / Rev. 0

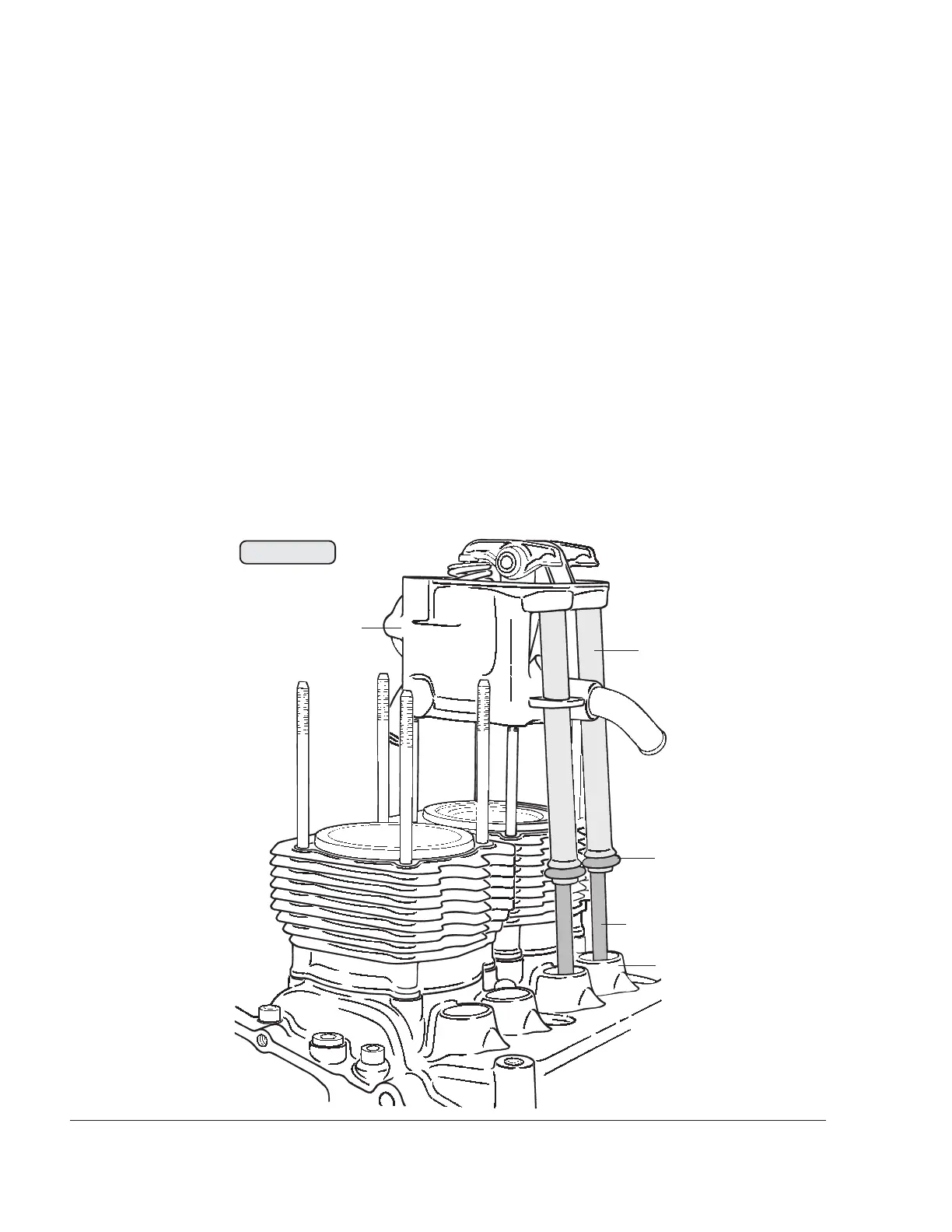

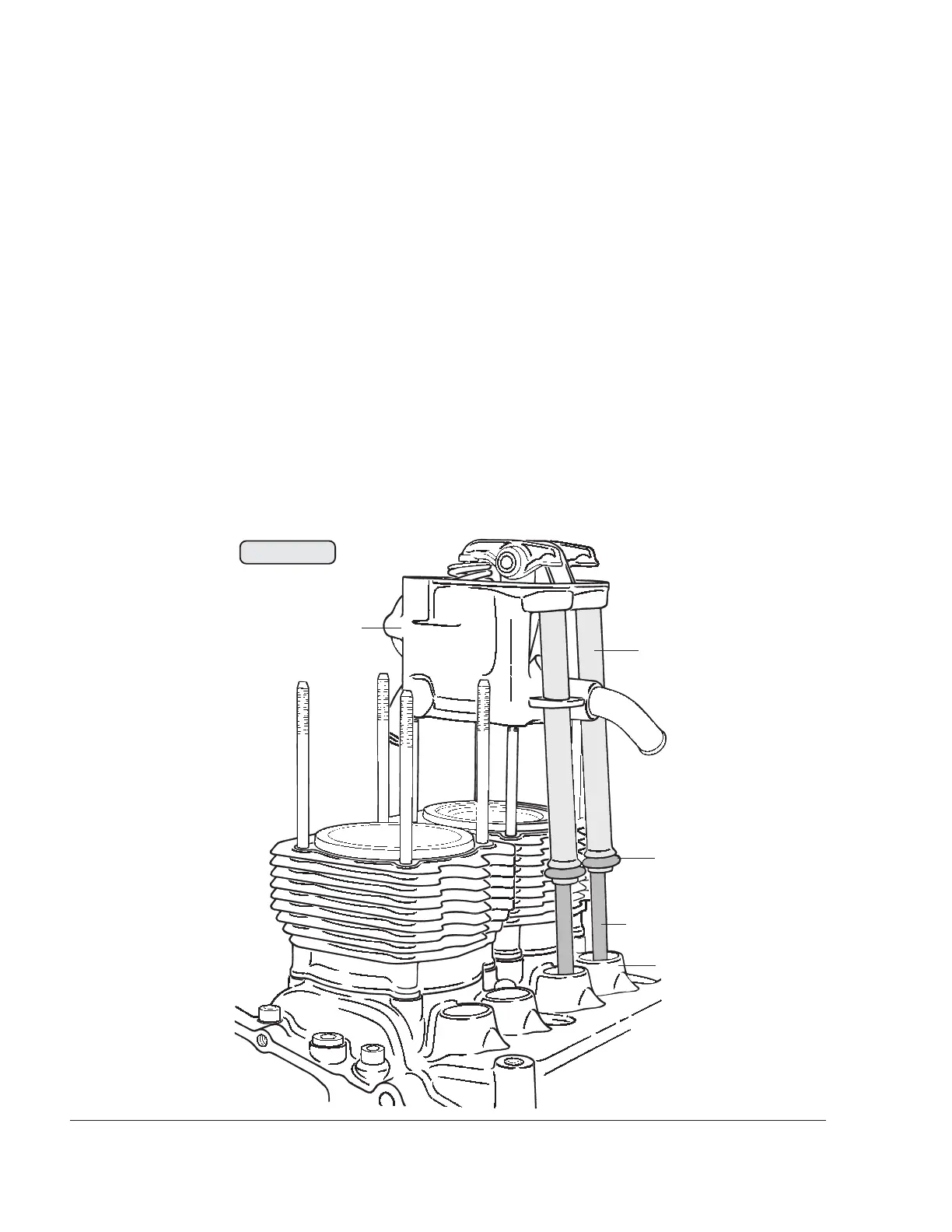

d02622

Keep both push rods (6) in position in the oil return tubes (7), seal oil bore of push

rods with finger and remove cylinder head (8). The oil return tubes remain with

the cylinder head. Remove O-rings (9) 16x15 from the oil return tubes or from

the crankcase (10).

Store cylinder head in such a way that the sealing surface and oil return tubes

are not damaged. Lift out oil filled push rods, stop oil from dripping by sealing

with finger. Coordinate push rods with cylinder heads to prevent any mix-up.

Mark the installation position of the push-rod with a suitable pen (e.g. touchup

pen) (e.g. ¨IV1“ for intake valve cylinder 1). If the parts are refitted in exactly the

same position and assignment as before, the push-rods can be used again. This

is because the parts have become broken in to each other in the course of

operation before disassembly.

00278

Fig. 72-58

6

7

8

9

10

Loading...

Loading...