BRP-Rotax

Maintenance Manual

Effectivity 912/914 Series

Edition 1 / Rev. 0

72-00-00

page 65

May 01/2007

d02622

Oil carbon residue on up to max 20% of the moving path is permissible.

See Fig. 72-67.

■ CAUTION: If there are heavier deposits, the valve may already

have overheated and must be replaced. There is a

danger of valve fracture at the weld.

Carry out a visual inspection of the 3 retaining grooves (3) on the valve

stem for damage or wear. To check the wear, fit a new valve cotter. It

must fit without perceptible clearance.

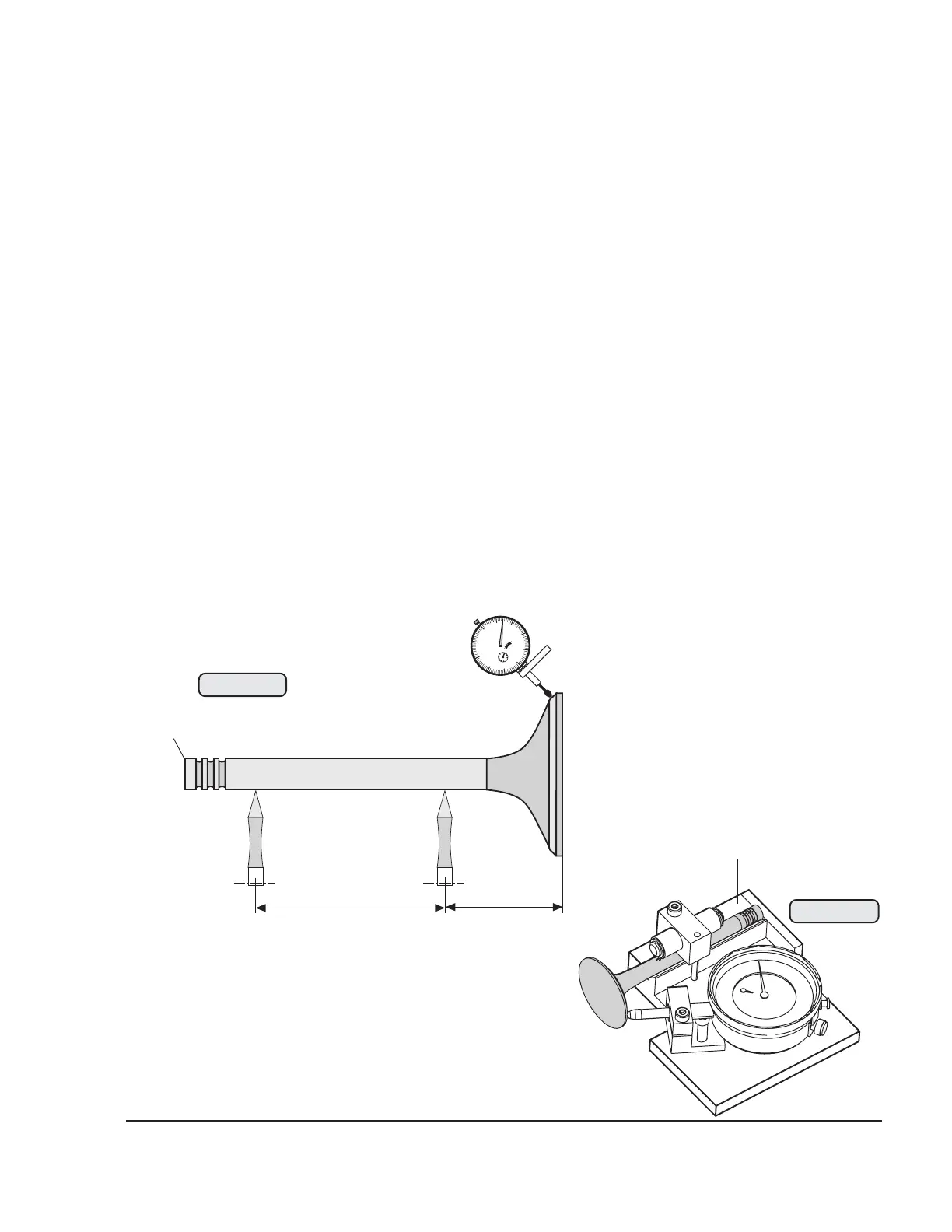

Place the valve on roller blocks (4), roll it and measure the max.

permissible out of true value VT02 on the valve disk using a dial gauge.

See Fig. 72-68.

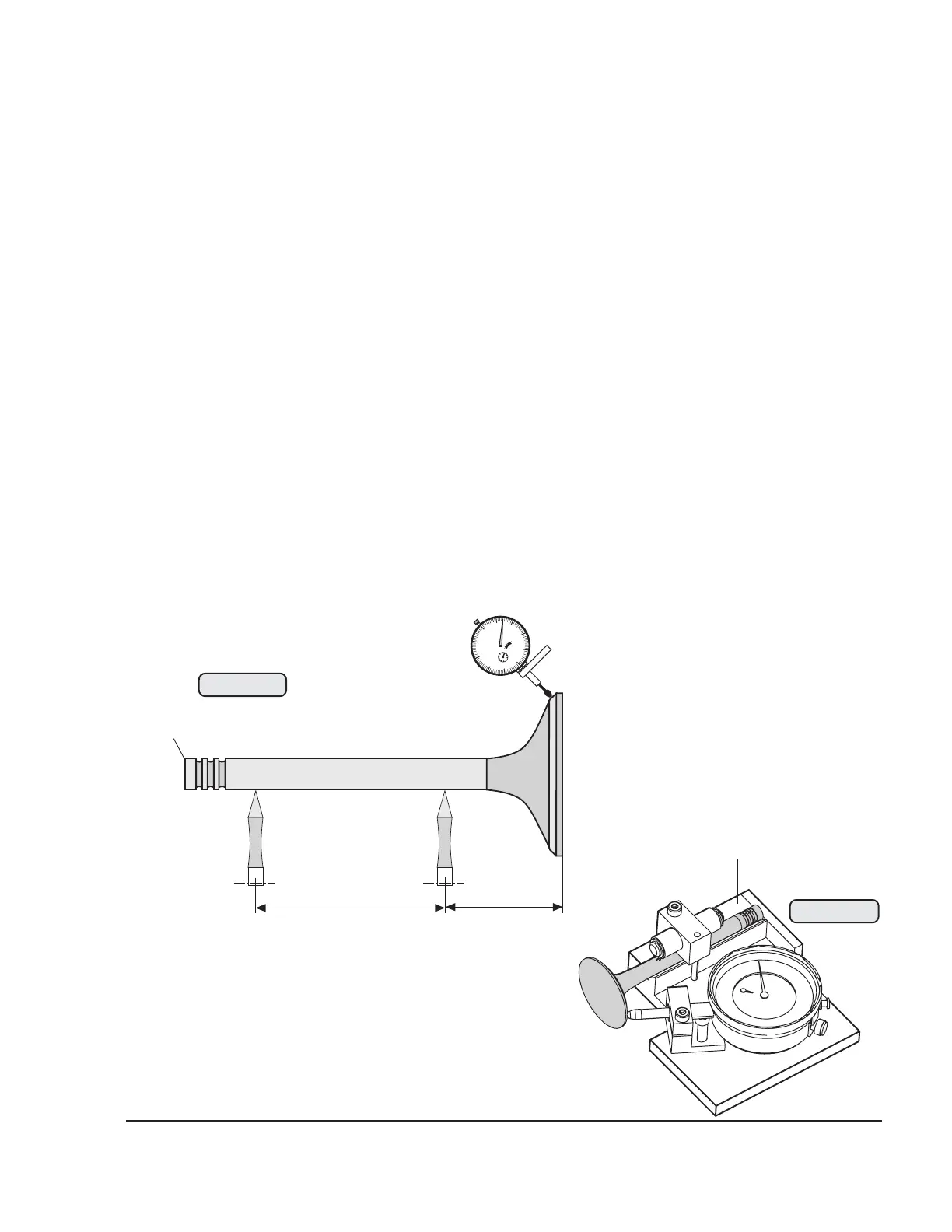

◆ NOTE: The out of true value can also be measured with the

dial gauge adapter assembly part no. 976140 (7). See

Fig. 72-69.

See 72-00-00 sec. 4.

0

10

20

30

40

50

60

70

80

90

0.01mm

1

2

3

4

5

6

7

8

9

0

~45 mm

~25 mm

VT02

5

44

07428

Fig. 72-68

07574

Fig. 72-69

7

(1.77 in.) (0.98 in.)

Loading...

Loading...