Effectivity 912/914 Series

Edition 1 / Rev. 0

page 13

May 01/2007

d02623

73-00-00

BRP-Rotax

Maintenance Manual

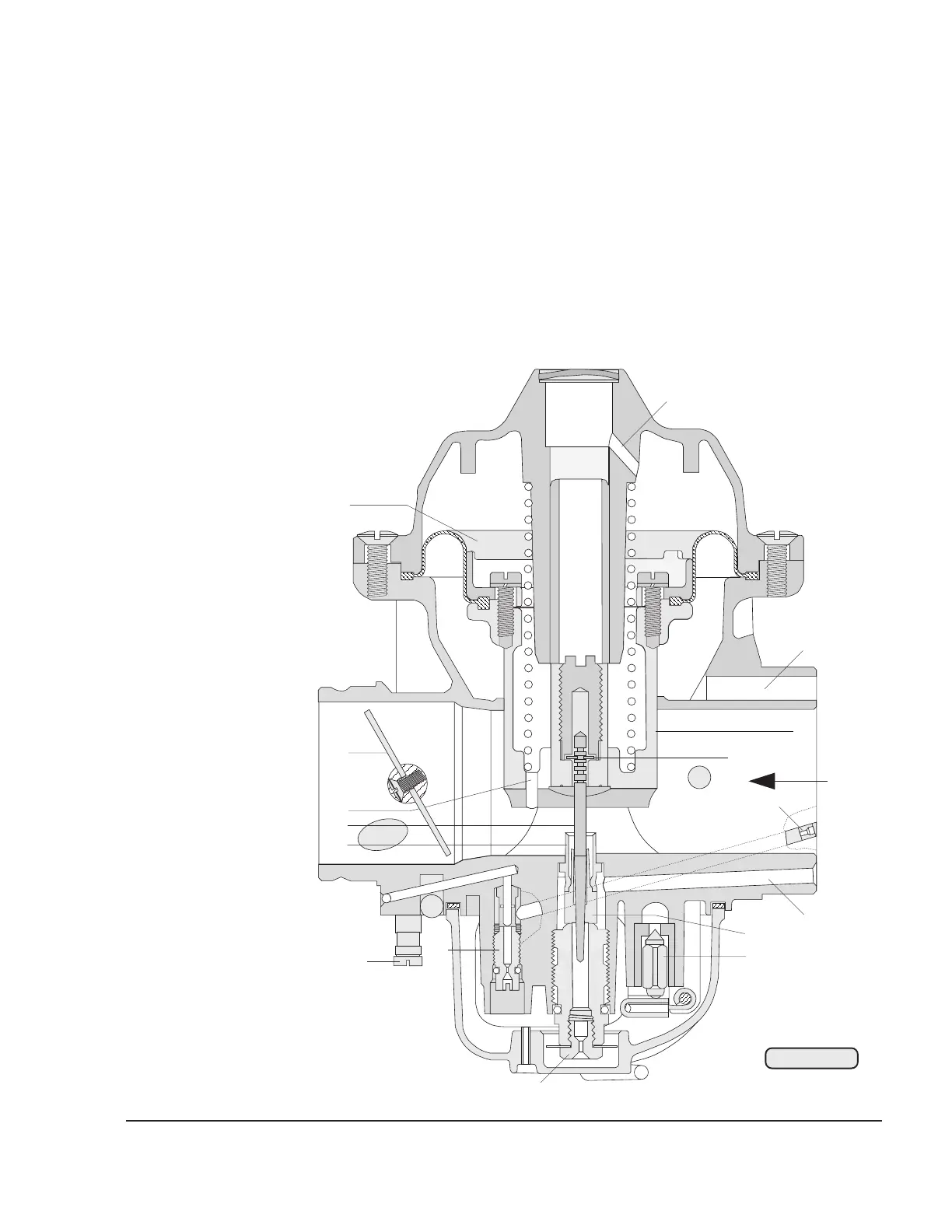

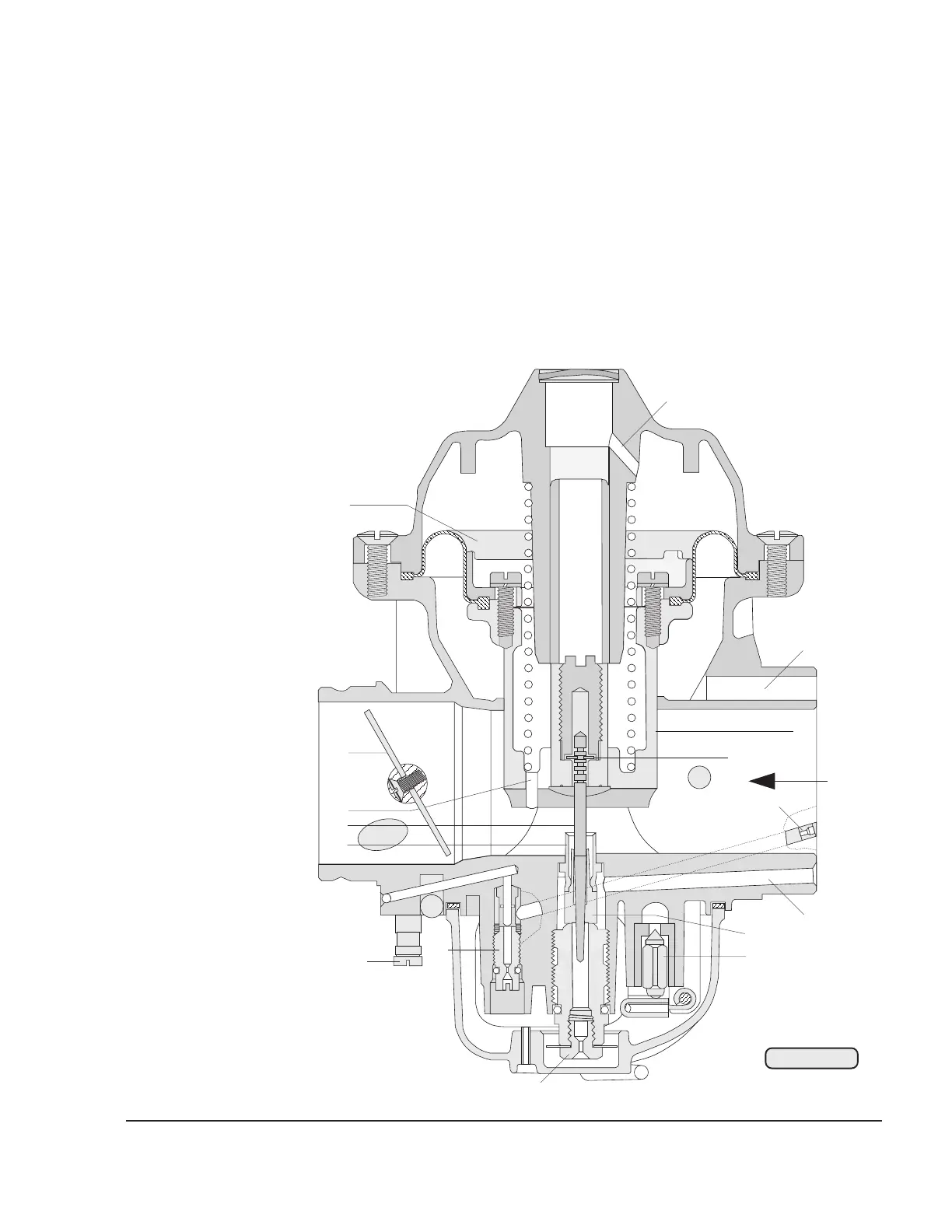

On its way from the float chamber to the venturi, the fuel passes through the

main jet (7), the mixing tube and the needle jet and in the diffuser tube (8) is pre-

mixed with air which is brought in from the air filter via the air duct (9) and the

atomizer in an annular flow around the needle jet. This air flow assists the

atomizing process and favors fuel distribution in the manifold.

The jet needle (10), which is responsible for part load, is kept in the defined

position by the retaining clip (11).

14

13

11

9

16

4

15

8

10

12

1

3

6

7

5

2

02931

Fig. 73-6

Loading...

Loading...