73-00-00

page 42

May 01/2007

Effectivity 912 Series

Edition 1 / Rev. 0

d02623

BRP-Rotax

Maintenance Manual

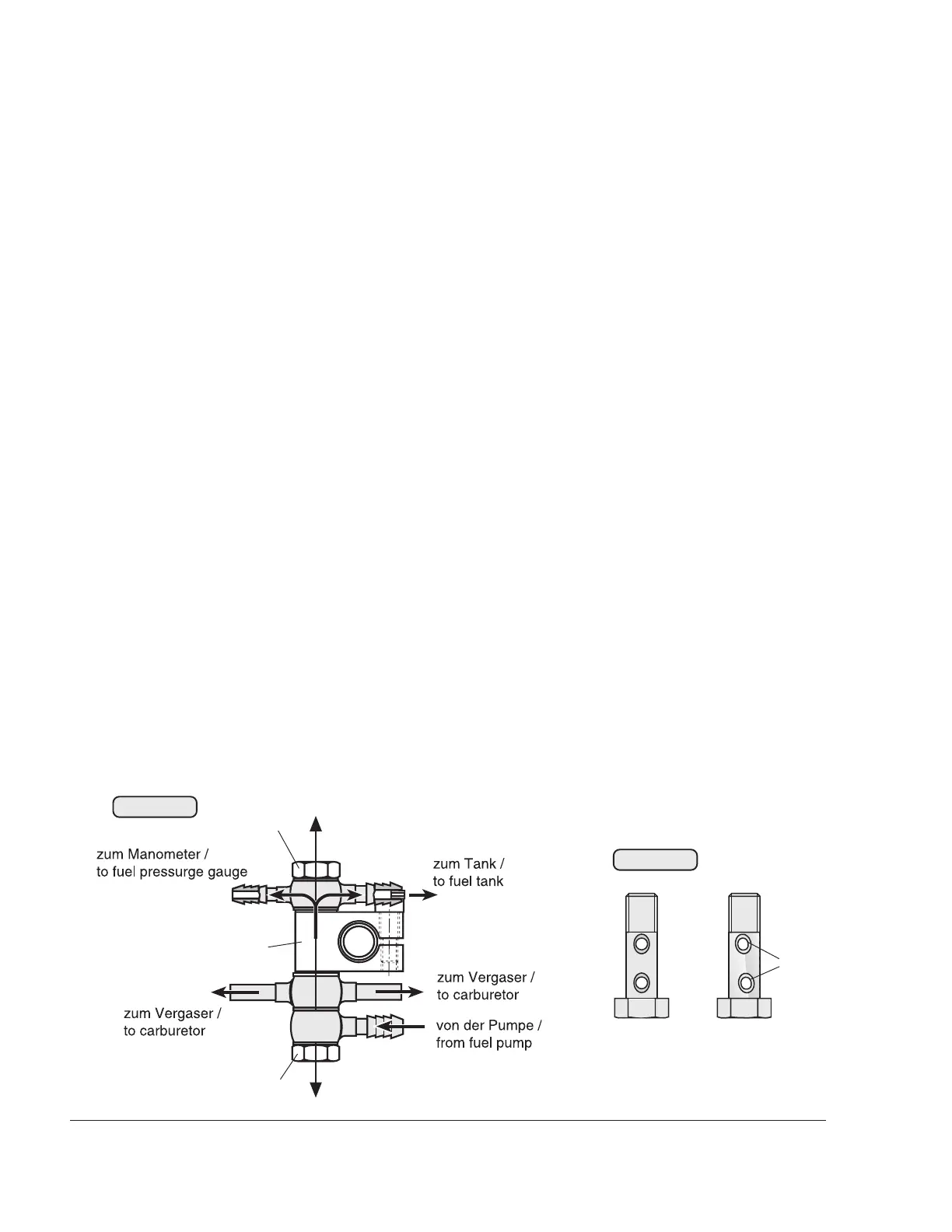

All fuel lines lead to the fuel manifold. Unscrew the banjo bolts (14).

Remove the fuel line (15) (hose line).

Now the two fuel lines (1, 6), the ring hose nipple (16) (connection for

return line and pressure gauge) and 5 sealing rings (17) can be

removed.

Unscrew allen screw M10x1x8 (18) with the sealing ring (19).

Carry out a visual inspection of all fuel lines for damage and wear. Pay

particular attention to the formation of any cracks in the area of the

connections.

Check the lines for free passage with compressed air and inspect the

lines for scuffing marks.

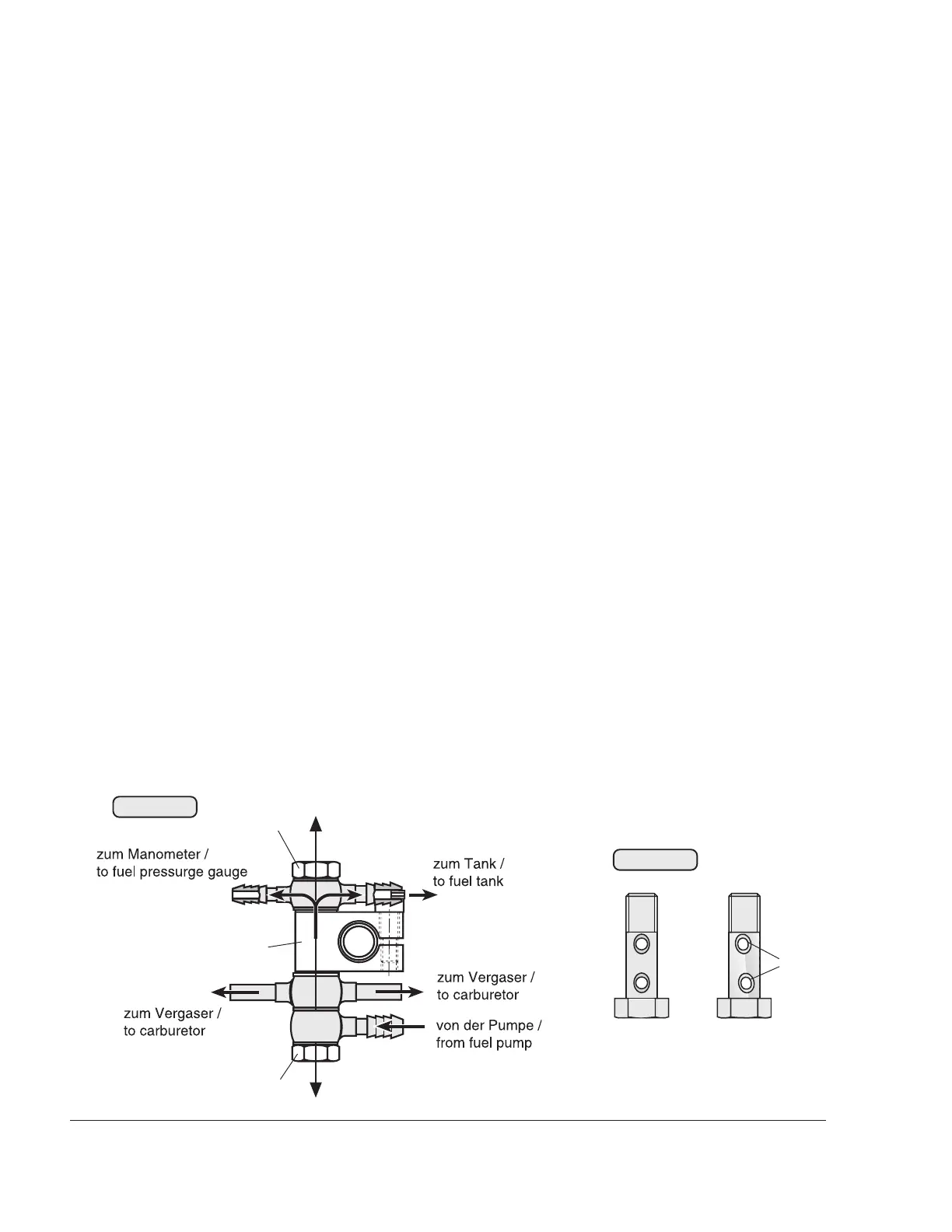

Carry out a visual inspection of the clamp block (20) of the fuel manifold,

the two banjo bolts (14) and the ring hose nipple (16).

◆ NOTE: It is not normally necessary to remove the clamp block

(20). However, if it should become necessary to re-

move it, it must be reattached with an allen screw

M5x16 (21) (tightening torque 6 Nm (53 in.lb). Ensure

that it is refitted in the same position.

Inspect banjo bolts (14) for hairline cracks, deformation or tears in the

area of the hole (22). If the hole is visibly ovalshaped, the banjo bolt has

been overstretched and must be replaced. See Fig. 73-36.

■ CAUTION : In the event of leaks, the max. permissible torque must

never be exceeded.

08211

08212

Fig. 73-35

Fig. 73-36

14

14

20

22

Loading...

Loading...