BRP-Rotax

Maintenance Manual

Effectivity 912/914 Series

Edition 1 / Rev. 0

72-00-00

page 63

May 01/2007

d02622

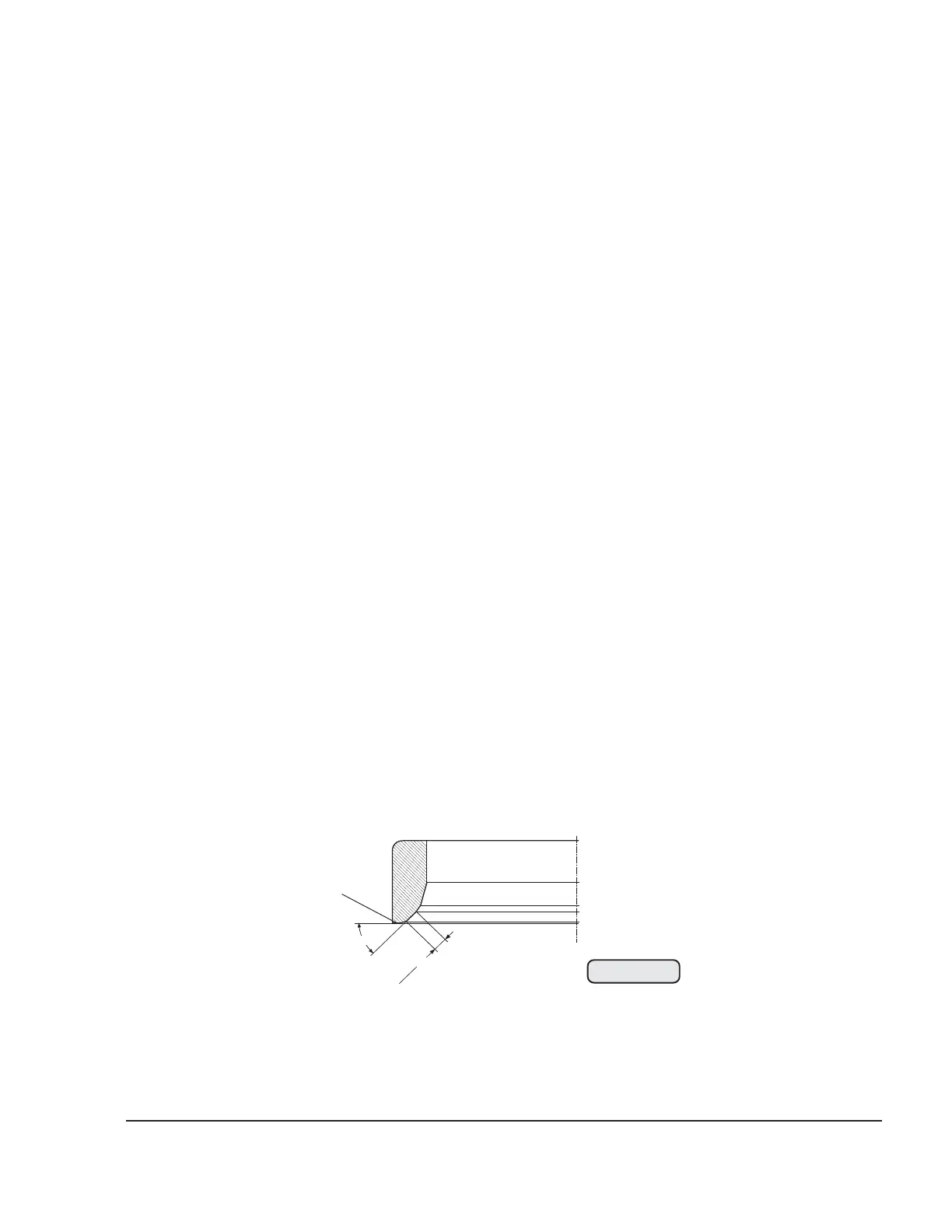

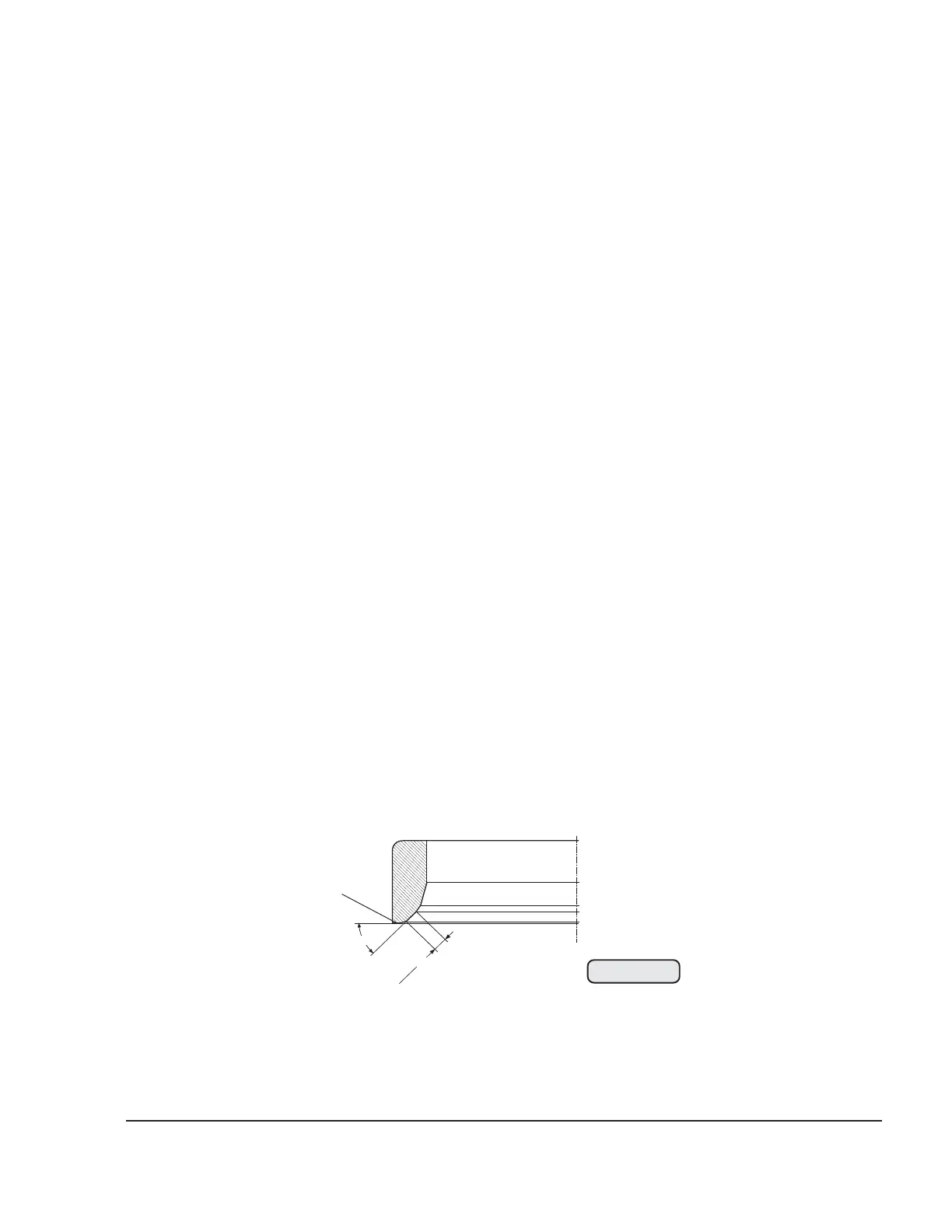

3.11.4) Valve seats

See Fig. 72-66.

Carry out a visual inspection of the valve faces for damage and wear.

Apply engineers blue evenly to the valve faces and fit the valves into the

respective valve guides. Turn the valve under gentle pressure to

produce a clear imprint of the sealing surface on the valve seat ring.

Ensure that the sealing surface of the valve seats (1) is clean and if

necessary, regrind with valve lapping paste.

■ CAUTION: The annular imprint on the valve face must be a

continuous, unbroken ring.

The width of the imprint corresponds to the width of the

valve seat CH02.

■ CAUTION: If burned spots or deformation are detected, send the

cylinder head to a ROTAX

authorized overhaul facility

for overhaul.

See 72-00-00 sec. 4.

Maß

dim.

45°

00285

CH02

1

Fig. 72-66

Loading...

Loading...