73-00-00

page 22

May 01/2007

Effectivity 912/914 Series

Edition 1 / Rev. 0

d02623

BRP-Rotax

Maintenance Manual

2

b

a

r

0

5

6

4

3

2

1

7

x

0

,1

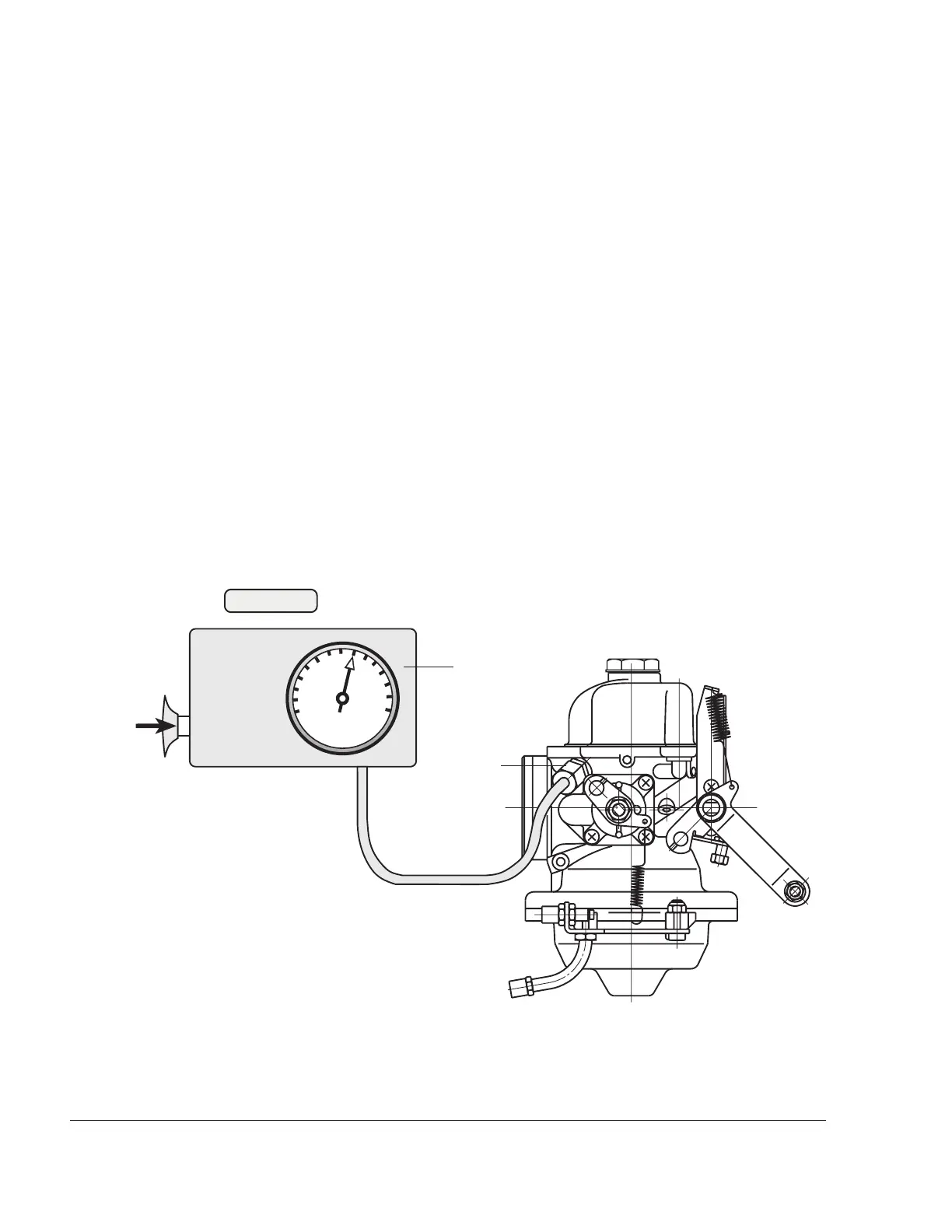

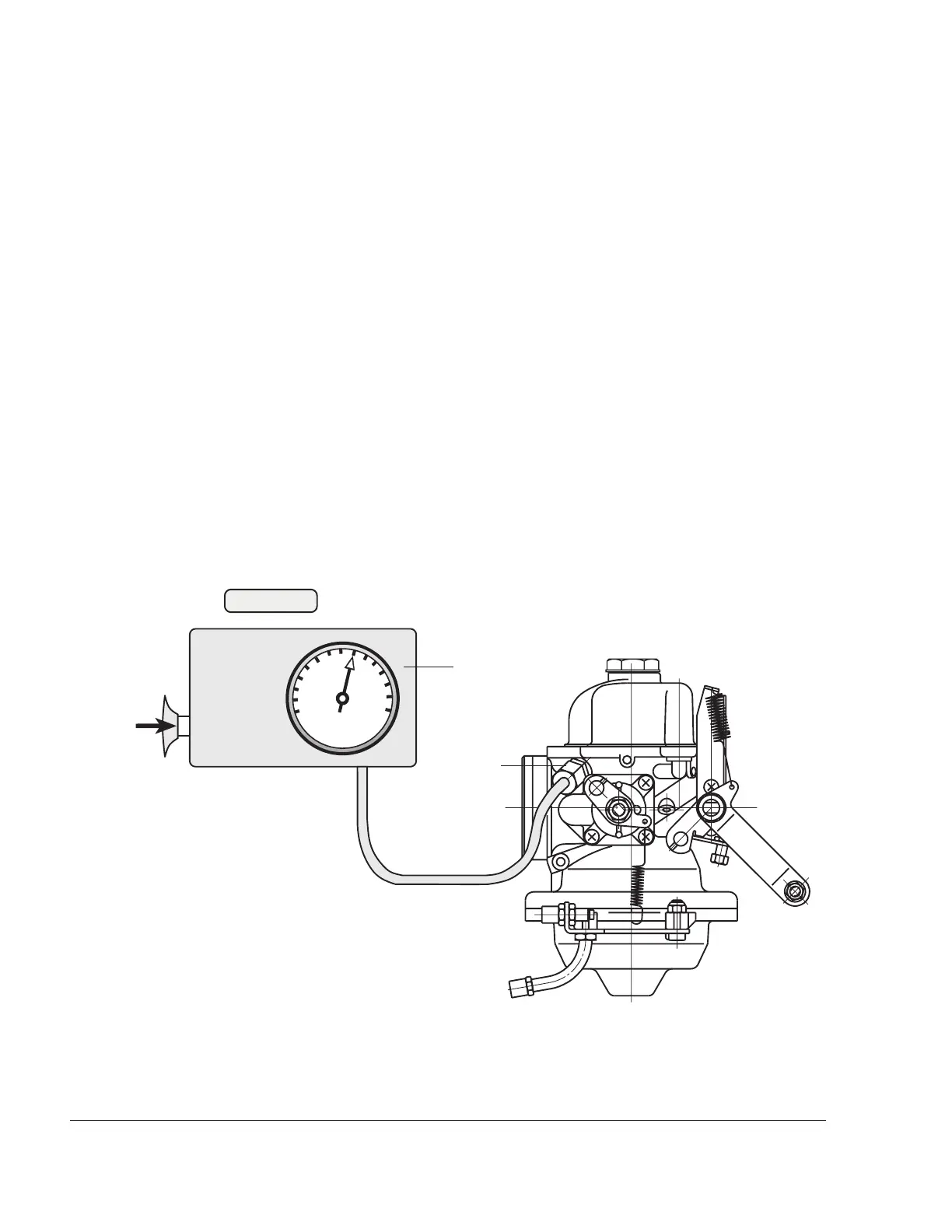

3.3.2) Float needle valve leakage test

See Fig. 73-12.

This check is carried out to ensure that the float valve seat is not leaking.

If the pressure is not maintained, pay particular attention during

disassembly to the float valve with the viton tip and the carburetor

housing.

Turn the carburetor upside down, as the float needle valve is only

closed in this position.

Connect pump (1) to the fuel supply line (2) and generate an excessive

pressure of approx. 0.4 bar (5.8 p.s.i.).

The excessive pressure must be maintained for about 5 seconds.

■ CAUTION: If excessive pressure drops, this indicates leakage

which may cause fuel overflow and in consequence

engine damage due to hydraulic shock.

Replacement of the float valve seat is not permissible.

07714

Fig. 73-12

1

2

Loading...

Loading...