Effectivity 914 Series

Edition 1 / Rev. 0

76-00-00

page 53

May 01/2007

d02626

BRP-Rotax

Maintenance Manual

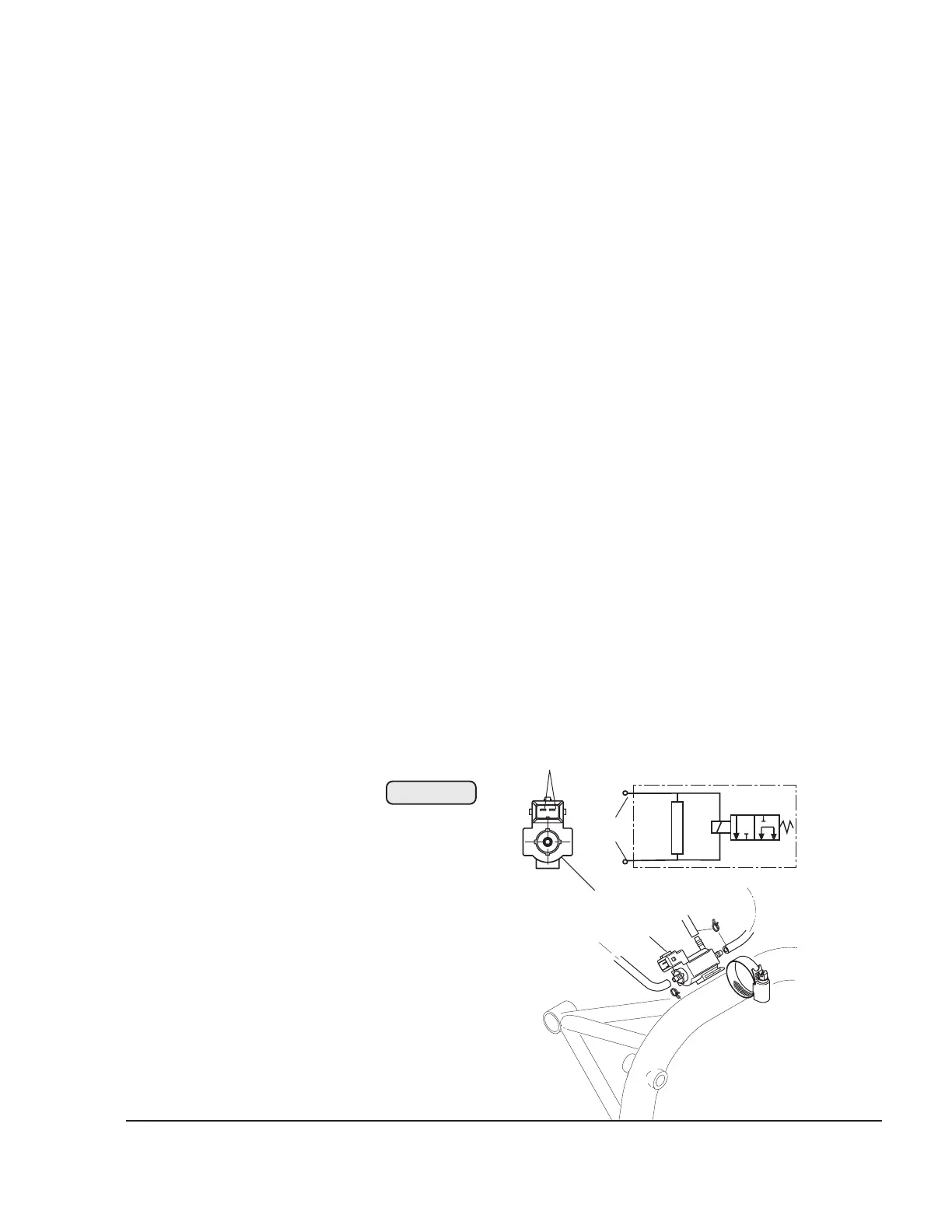

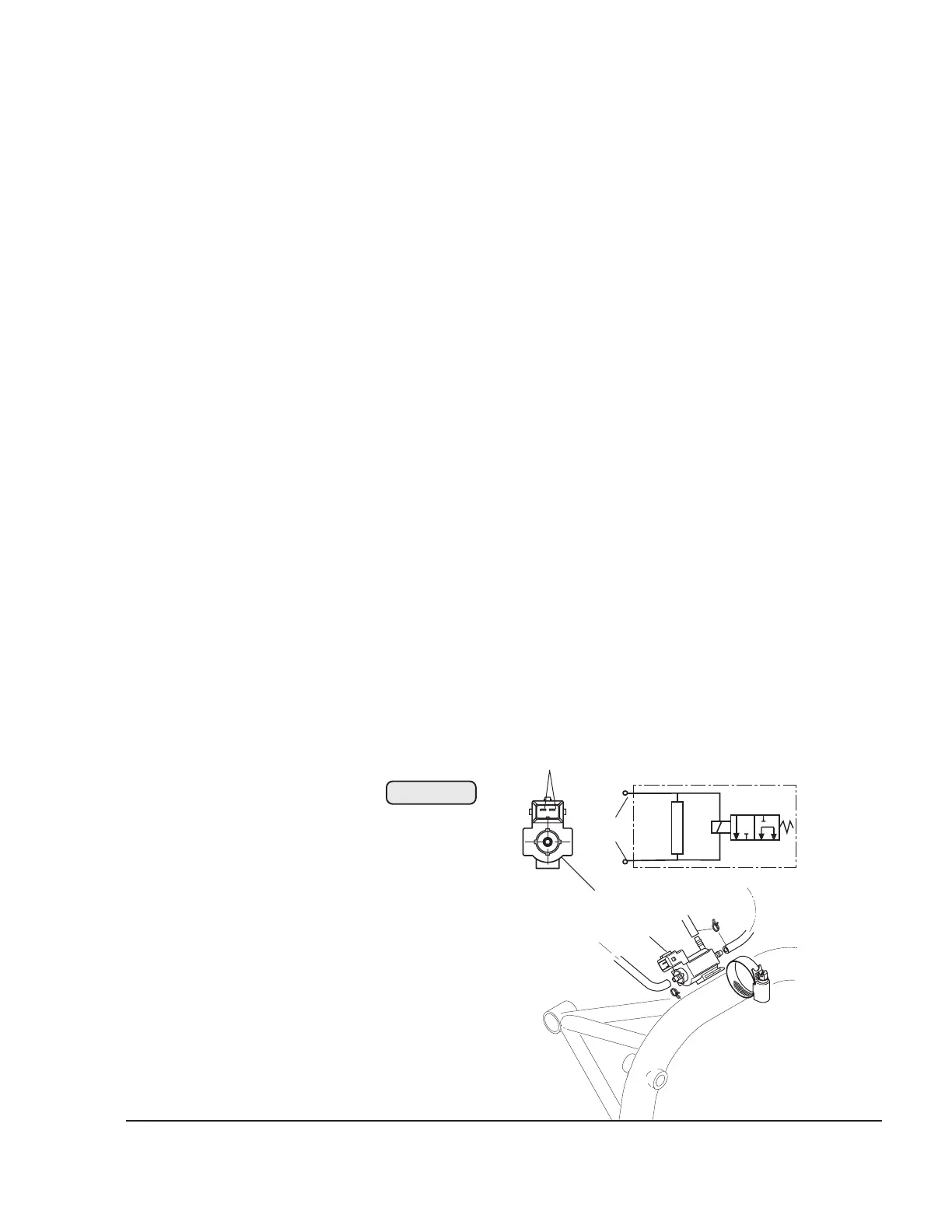

3.1.2.9) Three-way solenoid valve

See Fig. 76-50

The 3-way solenoid valve (1) is installed on the engine

suspension frame or directly on airbox on newer engines.

■ CAUTION: In the event of physical damage, mechanical

defects or readings outside tolerance, replace

the part without delay.

- Inspection for physical damage.

- check for pneumatic passage

Disconnect the pressure connection lines. See 73-00-00

sec. 2.7.

- check the mixture enrichment (dynamic)

To do so, fit a T-fitting into line between solenoid valve and

float chamber to facilitate the measuring by pressure gauge

of the pressure at airbox pressure exceeding 1250 hPa.

The T-fitting may remain in place, but for standard opera-

tion it must be securely closed.

- Measure the resistance between the two terminals (2):

- Disconnect plug connection with wiring harness but

reestablish immediately after completion of check

and verify tight fit and engagement of catch.

- resistance at 20 °C (68 °F): 28.3 to 31.1 Ω

00060

1

2

1

Fig. 76-50

Loading...

Loading...