Keeping the World Flowing

33

5.3 Actuator Analogue Input Feedback

In conjunction with the Profibus DP Module an optional

analogue monitoring card can be added (taking up the

second option card space).

This card can be used, to report over the Profibus network,

an analogue variable. It can be connected to another piece

of equipment near the actuator from which feedback is

required, such as level sensors, pressures sensors or flow rate

sensors, etc.

The range of inputs available are;

•

0-5 mA

•

0-10 mA

•

0-20 mA

•

0-5 V

•

0-10 V

•

0-20 V

The analogue monitoring card is powered from the actuators

internal power supply and can provide a current source

for the feedback. The feedback values will be in the range

0x0000=0% - 0x03E8=100% (0-1,000).

The card will need to be calibrated to the device during

set-up of the unit. To do this, apply a 100% signal and write

any non-zero number to parameter 35. For more information

please consult the Rotork technical manual.

5.4 Configuring the Registers to be Exchanged in Cyclic

Communication

In the start-up routine for Profibus communication the card

firstly enters parameterisation mode and adjusts the card

parameters according to the GSD file settings. Next the card

enters configuration mode where the configuration settings

in the GSD file are used to determine the registers to be

exchanged with the PLC during the normal cyclic messaging.

The configuration stage allows for the tailoring of the

registers to be exchanged to allow the system to be tuned to

improve data throughput. If certain information or controls

are not required by the PLC then they may be left out of data

exchange by choosing the appropriate configuration.

Both the PLC and the card must be aware of the

configuration chosen for successful data exchange.

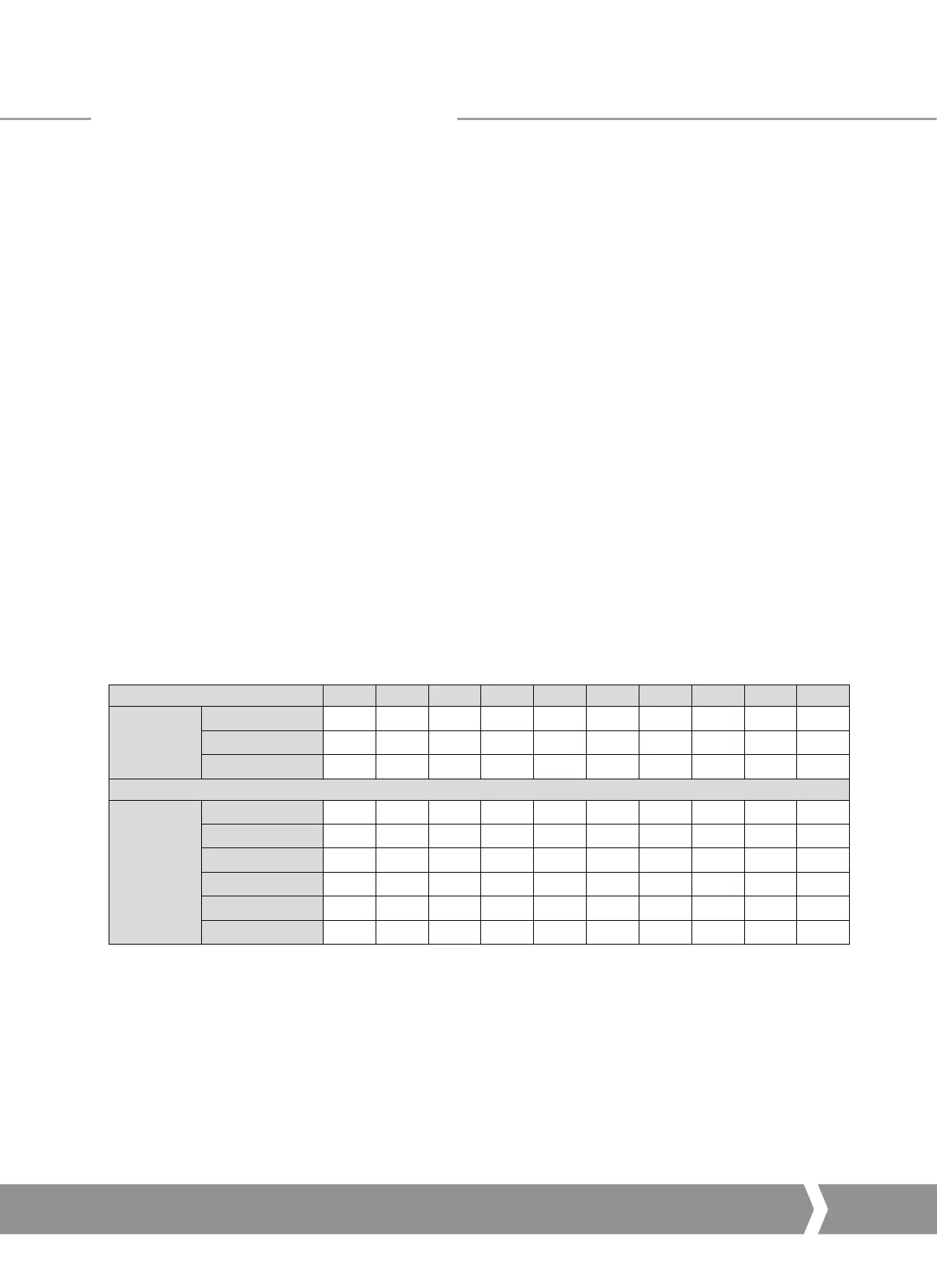

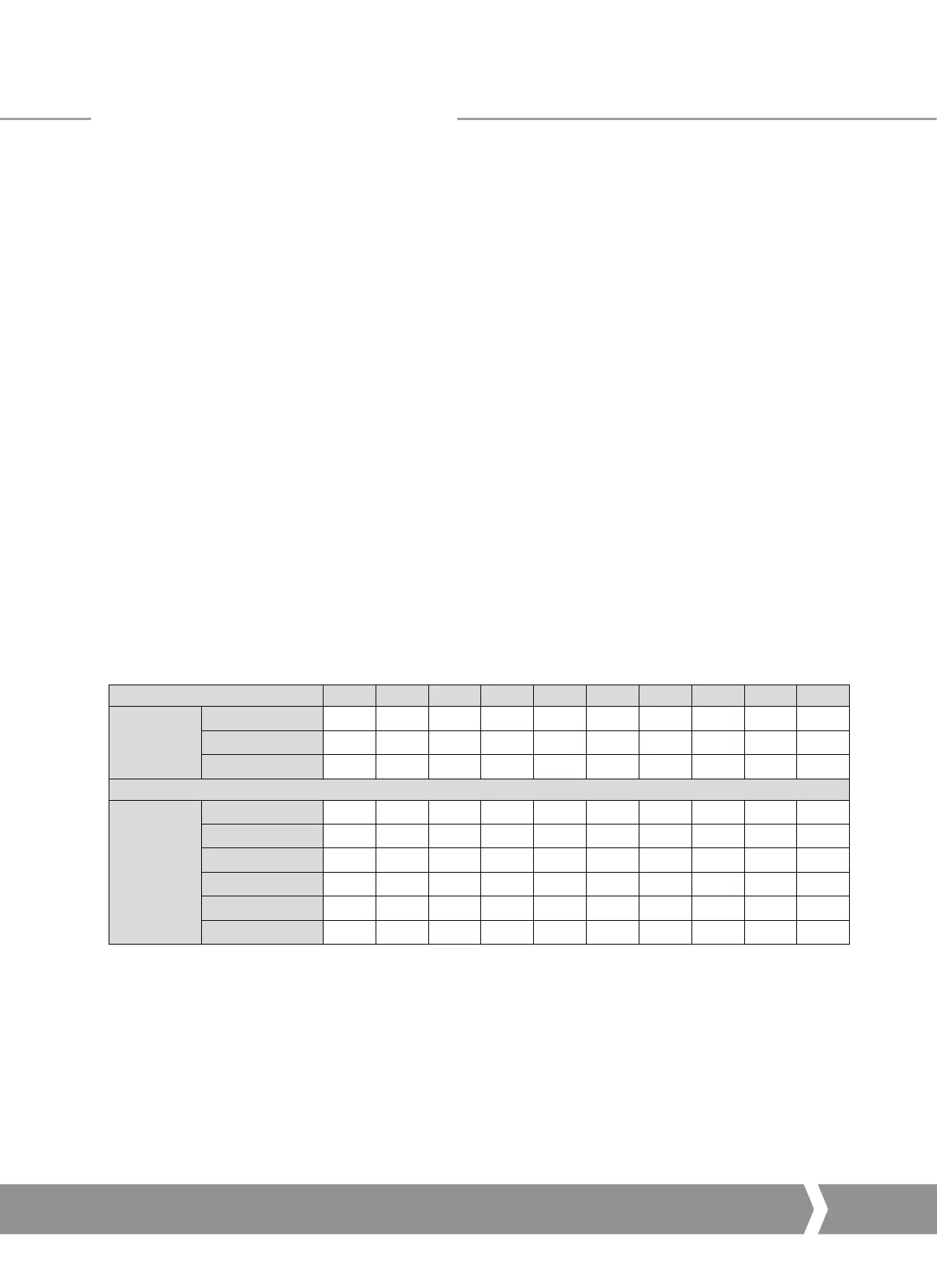

The Profibus DP Module has 10 possible configurations as

indicated in the table. The default value is Configuration 1.

The PLC must send a Check Configuration message during

start up to confirm the Configuration to be used.

Configuration 1 2 3 4 5 6 7 8 9 10

OUTPUTS

(16 Bits each)

ACTCON

ü ü ü ü ü ü ü ü ü

✗

POS-DV

ü

✗

ü

✗

ü

✗ ✗

ü

✗ ✗

O-STAT

ü

✗ ✗ ✗ ✗

ü ü ü ü

✗

INPUTS

(16 Bits each)

IDATA1 & IDATA2

ü ü ü ü ü ü ü ü ü ü

IDATA3 & IDATA4

ü ü ü ü ü ü ü ü ü ü

TORQUE

ü

✗

ü

✗

ü ü

✗

ü

✗

ü

POISTN

ü

✗

ü

✗

ü ü

✗

ü

✗

ü

TEMPER

ü

✗ ✗

ü ü

✗

ü

✗ ✗

ü

ANALOG

ü

✗ ✗

ü ü

✗

ü

✗ ✗

ü

The Actuator Cyclic Data Signals

A4 US

US

A4

US

A4

A4 US

Loading...

Loading...