Keeping the World Flowing

41

7.1.1 Limited Range Position Minimum and Maximum

(Parameter 1 and 2)

These parameter registers are used to define the positions

in the range of valve travel that will be reported as 0 to

100% if the whole travel from the closed position to the

open position is not used. In addition the position demand

set-point output value will also be modified to follow this

limited range.

It is possible to make the position data reported and the

position controller relate to a reduced span of actual valve

travel. In this mode the position data relates to the reduced

portion of the valve stroke. This is sometimes used where the

valve is required to have a 0% position (or 100% position)

that is not the same as the fully closed position (or fully open

position). These parameters define the actual limited range

of valve travel that will be used for the position reporting and

control by the positioner.

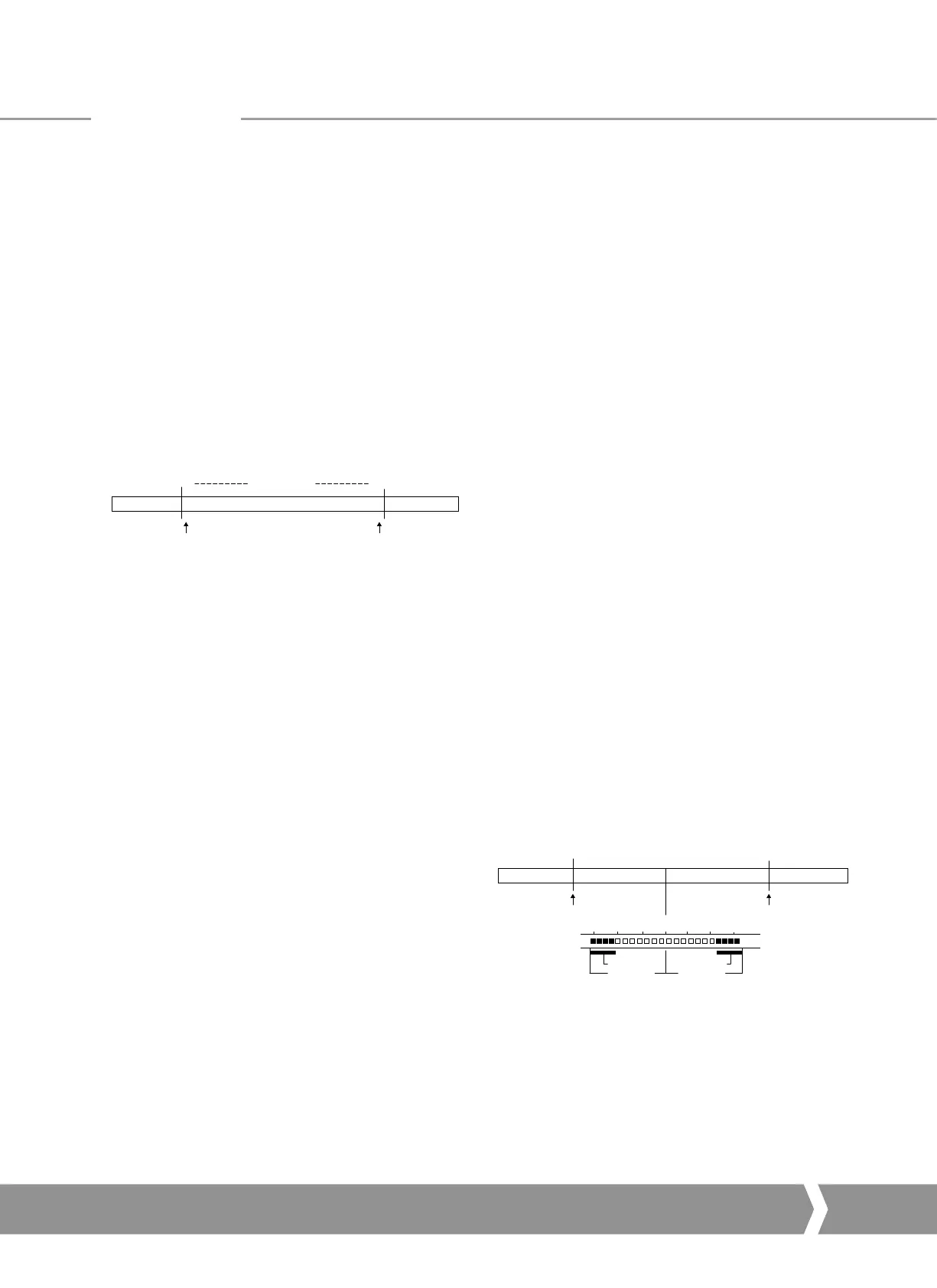

Valve Stroke

CLOSED OPEN

Position Minimum Setting Position MaximumSetting

0% 100%Reported Position

Fig. 24: Limited Range Position Control and Reporting

Note that the digital open and close commands will still make

the valve travel over its full stroke. The special case analogue

commands of 0% and 100% that would otherwise cause the

actuator to travel to the limit switch or torque off positions

are inhibited if values other than 0 and 100 are set in these

parameters (limited range position parameters).

The values inserted relate to the maximum total valve travel

between closed and open and represent the point in the full

stroke which will now be used for the limited stroke 0 and

100 values.

Parameters

7.1.2 Deadband and Hysteresis (Parameter 3 and 4)

When using position control by sending a value to the

Actuator Position DV set-point there are a number of

parameter registers used to tune the position controller and

reduce the possibility of damage to the actuator. These two

registers are set to prevent hunting around the set-point due

to high inertia of the valve. They will require adjustment for

each specific application. In addition the Motion Inhibit Timer

is used to ensure the actuator does not carry out an excessive

number of starts in a given period.

Deadband

The control used for the positioner is proportional only.

The PFU will run the actuator to the desired position and

then it stops. As the actuator and valve combination have

some inertia there is a possibility that the desired position

may be overrun and the positioner will then reverse the

direction of travel to make the valve adopt the desired

position. This overshoot and return may continue for a

number of cycles and is known as hunting. The valve and

actuator combination will hunt around the set-point if

the inertia is high. To prevent this from happening there

is a Deadband setting whereby once the actuator enters

the deadband the motor will be stopped. For example a

5% deadband will cause the motor to be stopped once

the actual position is within 5% of the desired position.

The inertia will then bring the actual position nearer the

desired position.

The deadband is the allowable error around the set point.

Hysteresis

In addition to the deadband a second setting, hysteresis,

further refines the performance of the position controller.

The positioner will run the actuator towards the setpoint

DV until the actual position is within the deadband minus

the hysteresis setting. This has the effect of instructing the

actuator to stop when it is nearer the DV. The actuator

will not restart unless it overshoots and runs outside the

deadband or a new command places the new desired

position outside the deadband.

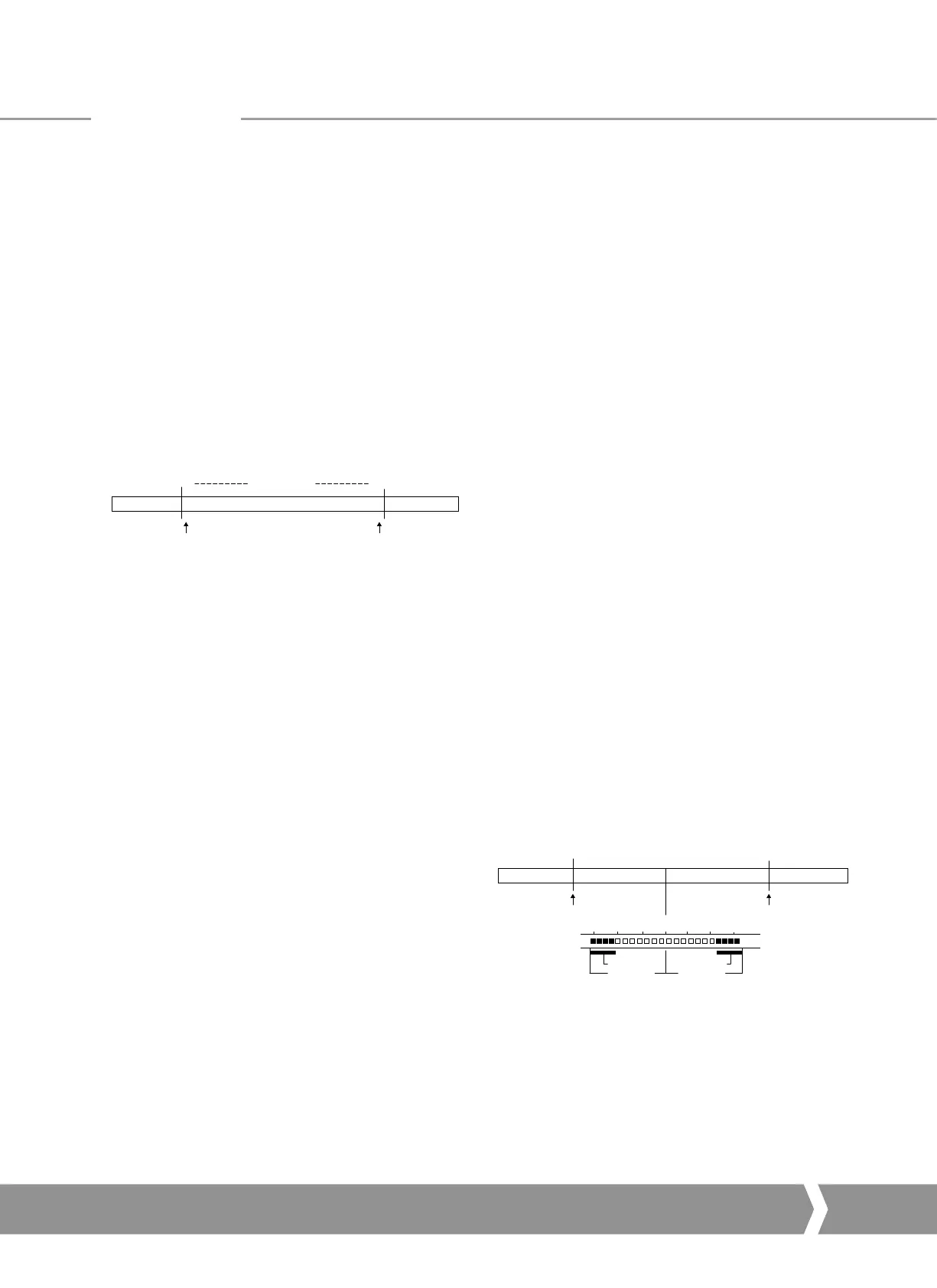

Fig. 25: Deadband and Hysteresis settings

The Hysteresis is the amount of movement inside the

deadband permitted before the motor stops.

Valve Stroke

CLOSED OPEN

Position Minimum Setting Position MaximumSetting

0%

47% 48% 49% 50% 51% 52% 53%

100%

Setpoint DV = 50%

Position MV = 50%

Hysterisis

Hysterisis = 1%

Hysterisis

A4 US

US

A4

US

A4

A4 US

Loading...

Loading...