Profibus Installation Manual

38

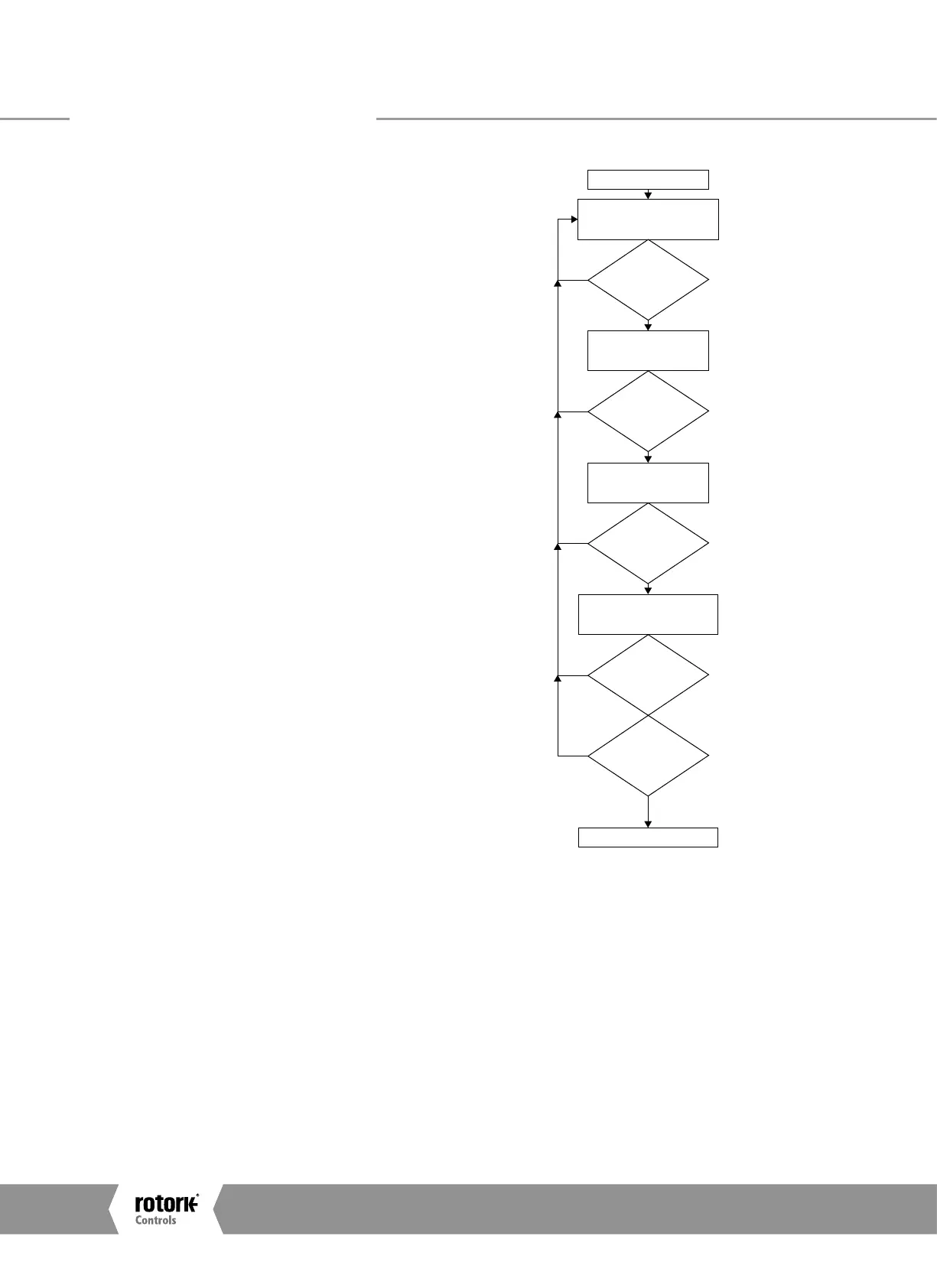

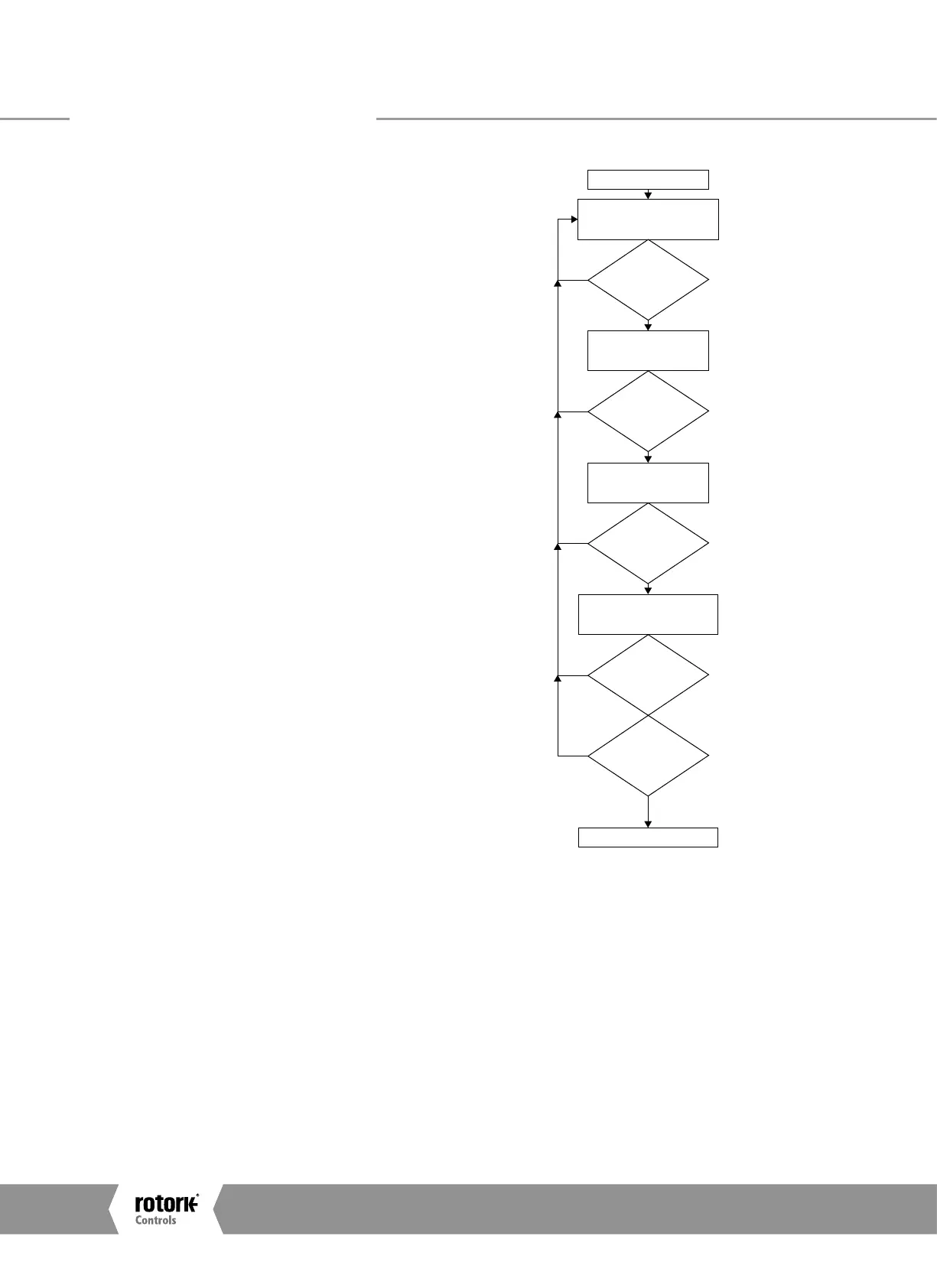

6.7 Basic Operation on Start up

Whenever a field device is powered up and it is found by the

PLC it will go through the standard Profibus procedure of

Parameterisation and Configuration before commencing Data

Exchange. This exchange can include altering the address if

the device has an address of 126 and the master supports

address changes – master class 2.

1) The first message – master sends a DIAG_req telegram.

2) The response should be a DIAG_res with diagnostic data

attached.

3) If this is correct a Set_Parameter telegram is sent with the

parameterisation data attached.

4) The response should be a Short Ack message.

5) If a correct response is received a Check_Config telegram

is sent

6) The response should be a Short Ack message.

7) If this is correct a DIAG_req telegram is sent.

8) The response should be a DIAG_res with diagnostic data

attached.

9) If DIAG is not reporting an error data exchange

commences.

The Parameterisation data is extracted from the GSD file for

the particular address of the slave device. The association

between the GSD to be used and the address is made in

the master during the configuration of the network on

the master (a table is created). The association can also be

defined in a Master 2 and sent to a Master 1 by the master

to master comms. Most master 1 devices permit the same

device type (as described in the GSD) to have different GSD

files, so allowing the GSD to be edited.

Editing the GSD file guarantees that a device coming on line

after having been switched off will have the correct settings.

If FDT or PDM changes the same parameters as those

installed by a GSD then the GSD values will replace those set

by the FDT or PDM when the device is switched off and on

again, or the PLC is powered off and back on, unless GSD

parameterisation is not permitted.

(See section 5.4 for information on the Configurations

allowed).

6.8 Static Diagnostics

Within the standard Profibus Diagnostics reply is a bit named

‘Static Diagnostic’. In the unlikely event that the PFU loses

communication with the main board to which it is connected,

this bit will be asserted to alert the user to this situation. If the

PFU is unable to communicate to the main board, the data

which is sent in data exchange communication is potentially

stale (not current). Therefore if the static diagnostic bit is

raised the user should be aware not to utilise that data and to

wait for the bit to be reset. If the bit does not de-assert itself

in a timely manner (i.e. after about 5 minutes) the user should

power cycle the actuator to regain communications.

Power On

Data Exchange

Master sends DIAG_req

telegram to slave

Master sends DIAG_req

telegram to slave

Master sends

Set_Parameter

Master sends

Check_Cong

Correct

DIAG_res

recieved

Correct

DIAG_res

recieved

DIAG

is reporting

error?

No

Yes

No

No

No

No

Correct

Response

recieved?

Correct

Response

recieved?

Fig. 23: Profibus Start Up Sequence

Profibus DP Communication

The static diagnostic bit is not expected to be seen under

normal operating conditions.

For actuators with a Profibus firmware version of V103 or

later: if the software is being updated in the CK main board,

communications to the PFU will be stopped, at this time the

Static diagnostic bit will be raised. As soon as the software

is updated and the communications to the PFU return, the

static diagnostics bit will be de-asserted. In older versions of

the Profibus firmware the same happens as described above

except that the diagnostic bit is not asserted.

A4US

US

A4

US A4

US

A4

Loading...

Loading...