A4US

US

A4

US A4

US

A4

A4 US

US

A4

US

A4

A4 US

22 IQ3 Full Configuration Manual – Section: Settings

4/5 Low Signal Pos

Range 0% to 100% open positions.

Used to set the position the actuator will move to when the

low analogue signal is applied for Analogue control or for a 0%

position command for Network options. Normally this will be set

at Closed Limit position (0%), unless positioning is required over

a reduced portion of full valve travel, for example, to prevent full

closure where valve throttling is required.

To change,

. The slider control will indicate the

position the actuator will move to when the low signal is

applied.

5/5 High Signal Pos

Range 0% to 100% open positions.

Used to set the position the actuator will move to when the High

analogue signal is applied for Analogue control or for a 100%

position command for Network options. Normally this will be set

at Open Limit position (100%), unless positioning is required over

a reduced portion of full valve travel, for example, to increase

positioning resolution for a butterfly valve where positioning is

required from Closed Limit position to 60% open position.

To change,

. The slider control will indicate the

position the actuator will move to when the high signal is

applied.

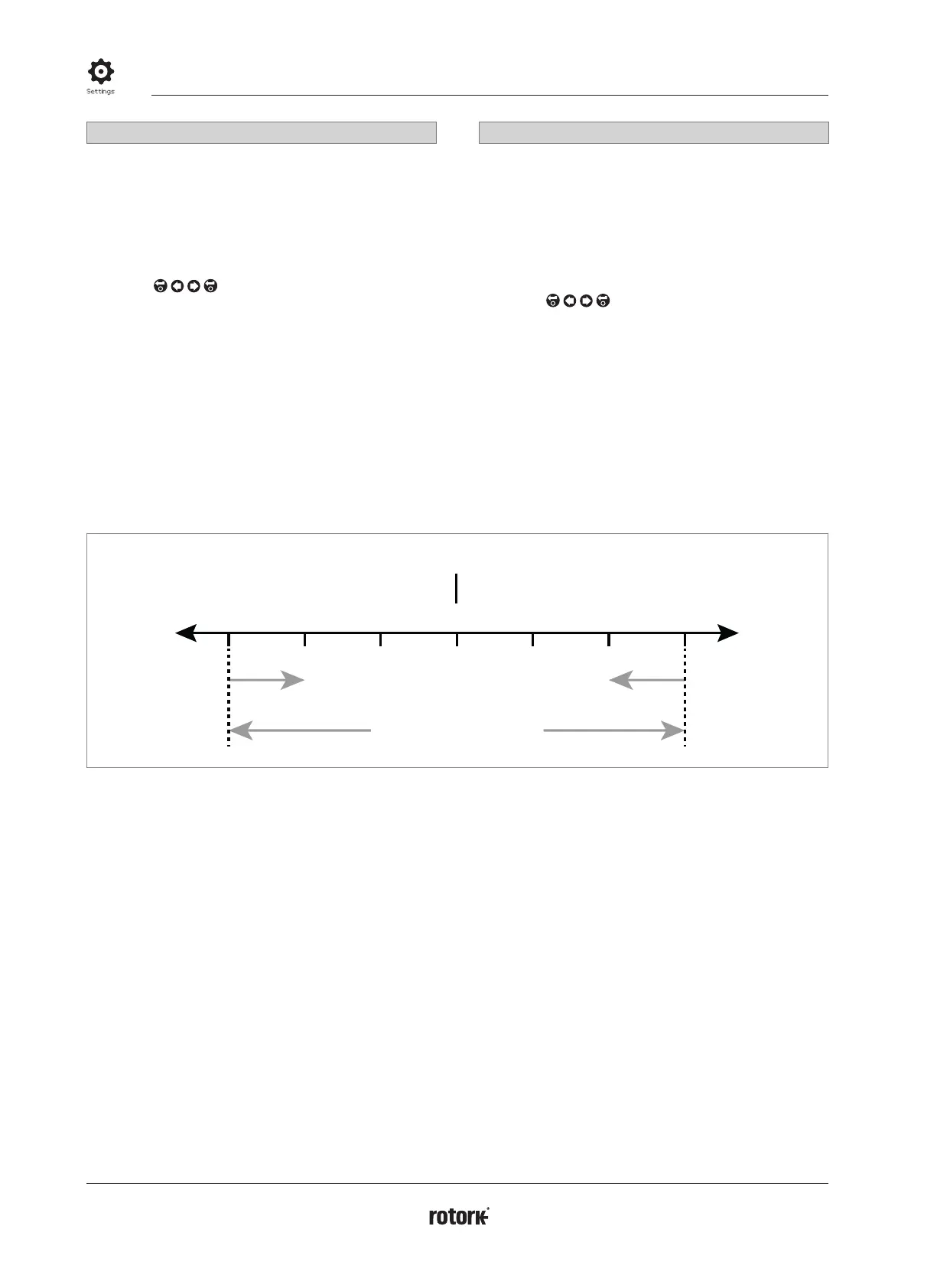

Figure 2.3-1 Example of Hysteresis and Deadband

Example: An actuator set with a 3% deadband and a 1%

hysteresis and a control system new Desired Value (DV) of 50%

will come to rest between 48% and 53% when moving from

a position less than 47%, and between 52% and 47% when

moving from a position greater than 53%.

Hysteresis = 1%

Deadband = 3%

DV

47% 48% 49% 50% 51% 52% 53%

OpenClose

The Deadband setting will be determined by the accuracy of

control required and valve overrun. Overrun is a factor of valve

and actuator inertia dependent on mass, speed, valve stiffness

and friction

2.3.2-4 Control – Remote – Positioning

continued

Loading...

Loading...