-:,:,,-~~ccc'

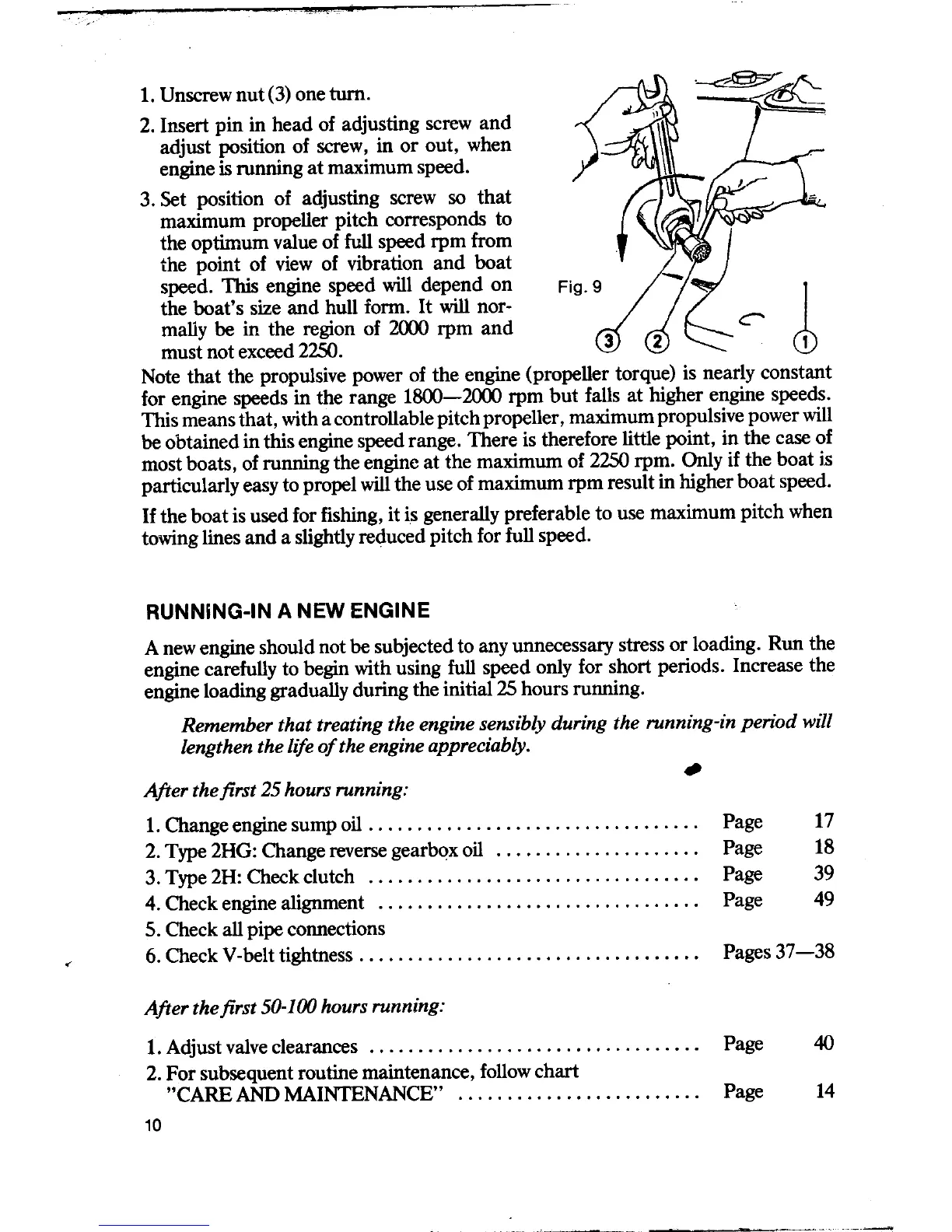

1. Unscrew nut (3) one turn.

2. Insert pin in head of adjusting screw and

adjust position of screw, in or out, when

engine is running at maximum speed.

3. Set position of adjusting screw so that

maximum propeller pitch corresponds to

the optimum value of fu11 speed rpm from

the point of view of vibration and boat

speed. This engine speed will depend on Fig.9

the boat's size and huIl form. It win nor-

mally he in the region of 200) rpm and

must not exceed 2250.

Note that the propulsive power of the engine (propeller torque) is nearly constant

for engine speeds in the range 1800-2(XX) rpm but falls at higher engine speeds.

This means that, with a controllable pitch propeller, maximum propulsive power will

he obtained in tros engine speed range. There is therefore little point, in the case of

most boats, of running the engine at the maximum of 2250 rpm. Only if the boat is

particularly easy to propel will the use of maximum rpm result in higher boat speed.

If the boat is used for fishing, it is generally preferable to use maximum pitch when

towing lines and a slightly reduced pitch for ful1 speed.

RUNNiNG-IN A NEW ENGINE

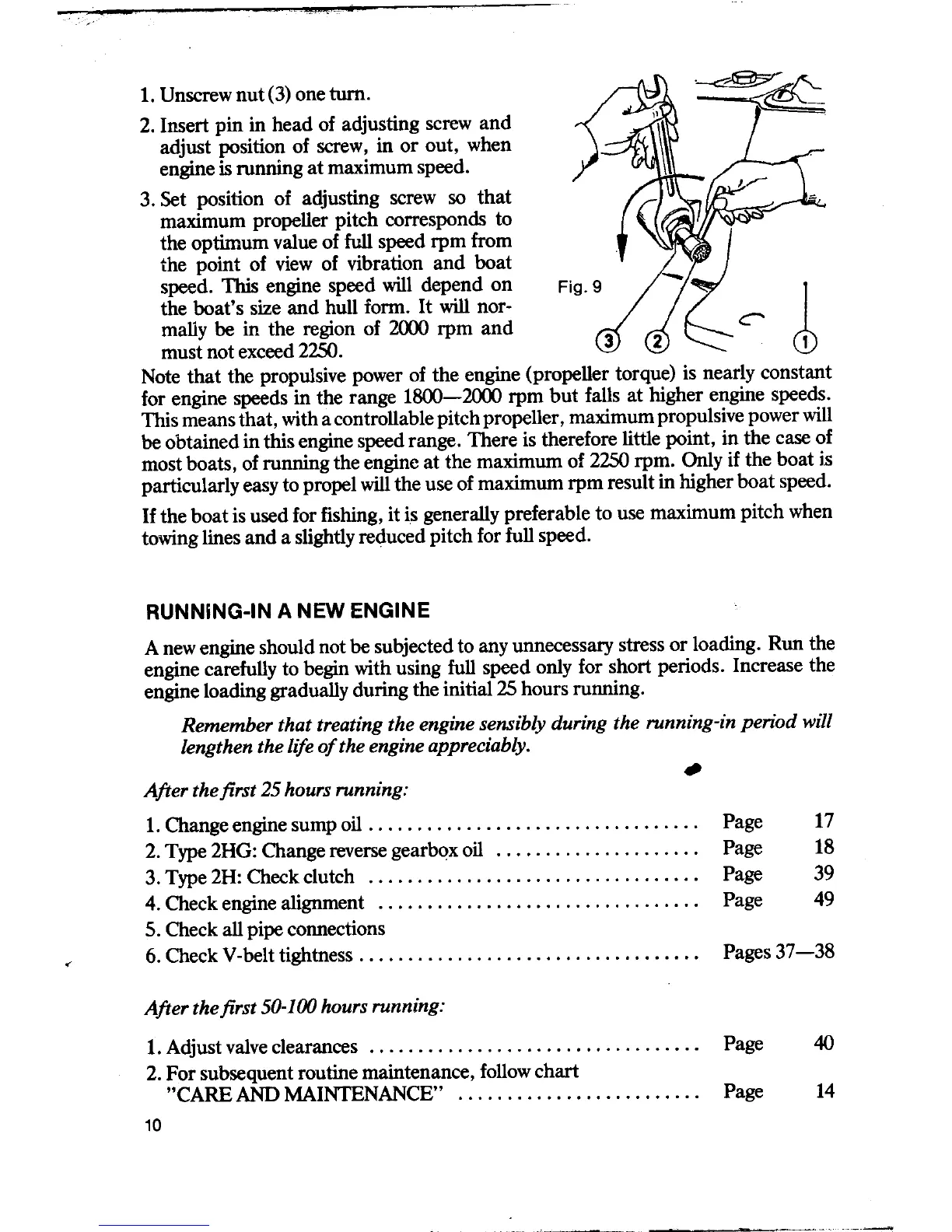

A new engine should not he subjected to any unnecessary stress or loading. Run the

engine carefully to begin with using full speed only for short periods. Increase the

engine loading gradually during the initial2S hours running.

Remember thaI treating the engine sensibly during the running-in period will

lengthen the life of the engine appreciably.

~

After thefirst 25 hours running:

I.Changeenginesumpoil Page 17

2. Type 2HG: Change reverse gearbü:x oil Page 18

3.Type2H:Checkclutch Page 39

4.Checkenginealignment Page 49

S. Check all pipe connections

. 6.CheckV-belttightness Pages 37-38

After the first 50-] ()(} hours running:

1.Adjustvalveclearances Page 40

2. For subsequent routine maintenance, follow chart

"CAREANDMAINTENANCE" Page 14

10

"~~ - -~~~--

Loading...

Loading...