- . ~

# :-~cc, ~,

"c , ;,-

r -"...'"

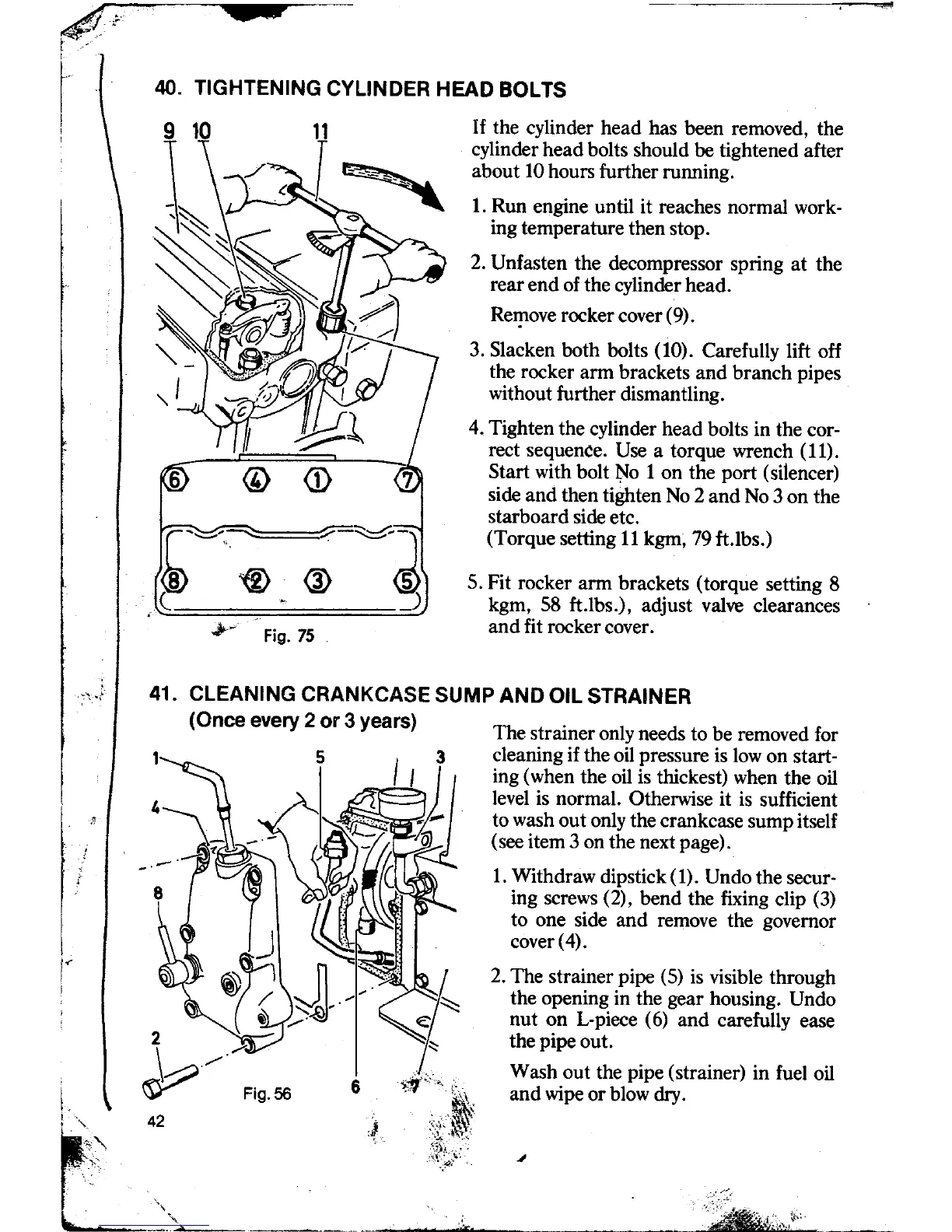

r 40. TIGHTENING CYLINDER HEAD BOL T5

i If the cylinder head bas been removed, the

I cylinder head bolts should he tightened after

about 10 hours further running.

1. Run engine until it reaches normal work-

ing temperature then stop.

2. Unfasten the decompressor spring at the

TeaT end of the cylinder head.

Re1!1°ve rocker cover (9).

3. Slacken both bolts (10). Carefully lift off

the rocker arm brackets and branch pipes

without further dismantling.

4. Tighten the cylinder head bolts in the cor-

rect sequenëe. Use a torque wrench (11).

Start with bolt ~o 1 on the port (silencer)

side and then tighten No 2 and No 3 on the

starboard side etc.

(Torque setting 11 kgm, 79 ft.lbs.)

5. Fit rocker arm brackets (torque setting 8

kgm, 58 ft.lbs.) , adjust valve clearances

and fit rocker cover.

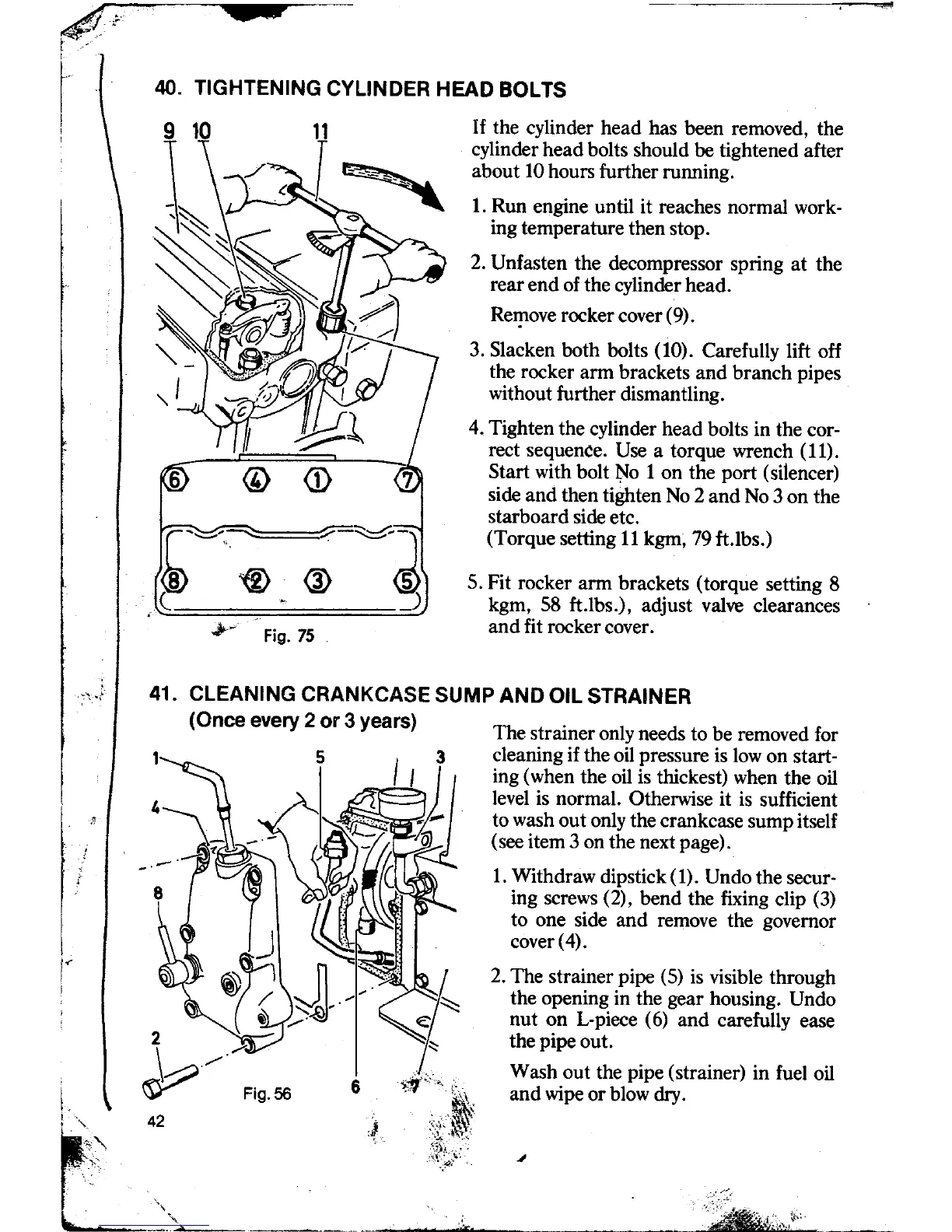

: 41. CLEANING CRANKCASE SUMP AND OIL STRAINER

(Once every 2 or 3 years) The strainer only needs to be removed foT

cleaning if the oil pressure is low on start-

ing (when the oil is thickest) when the oil

level is normal. Otherwise it is sufficient

I ; to wash out only the crankcase sump itself

~ i (see item 3 on the next page).

r j' 1. Withdraw dipstick (1). Undo the secur-

, ; ing screws (2), bend the fixing clip (3)

I to one side and remove the governor

cover (4).

/" 2. The strainer pipe (5) is visible through

! the opening in the gear housing. Undo

: nut on L-piece (6) and carefu1ly ease

the pipe out.

i _\ :;;.? Sj:':., , Wash.out the pipe (strainer) in fuel oil

\c '. ~ Fig. 56 6.iJf '.'~, and Wlpe or blow dry.

, " 42 J. ::;"i\':

, ~~.~:,:' .,

"

_._~ - ' -

Loading...

Loading...