Replacement of Shaft Drive Block

The propeller shaft is manufactured trom stainless steel and bas parallel threads.

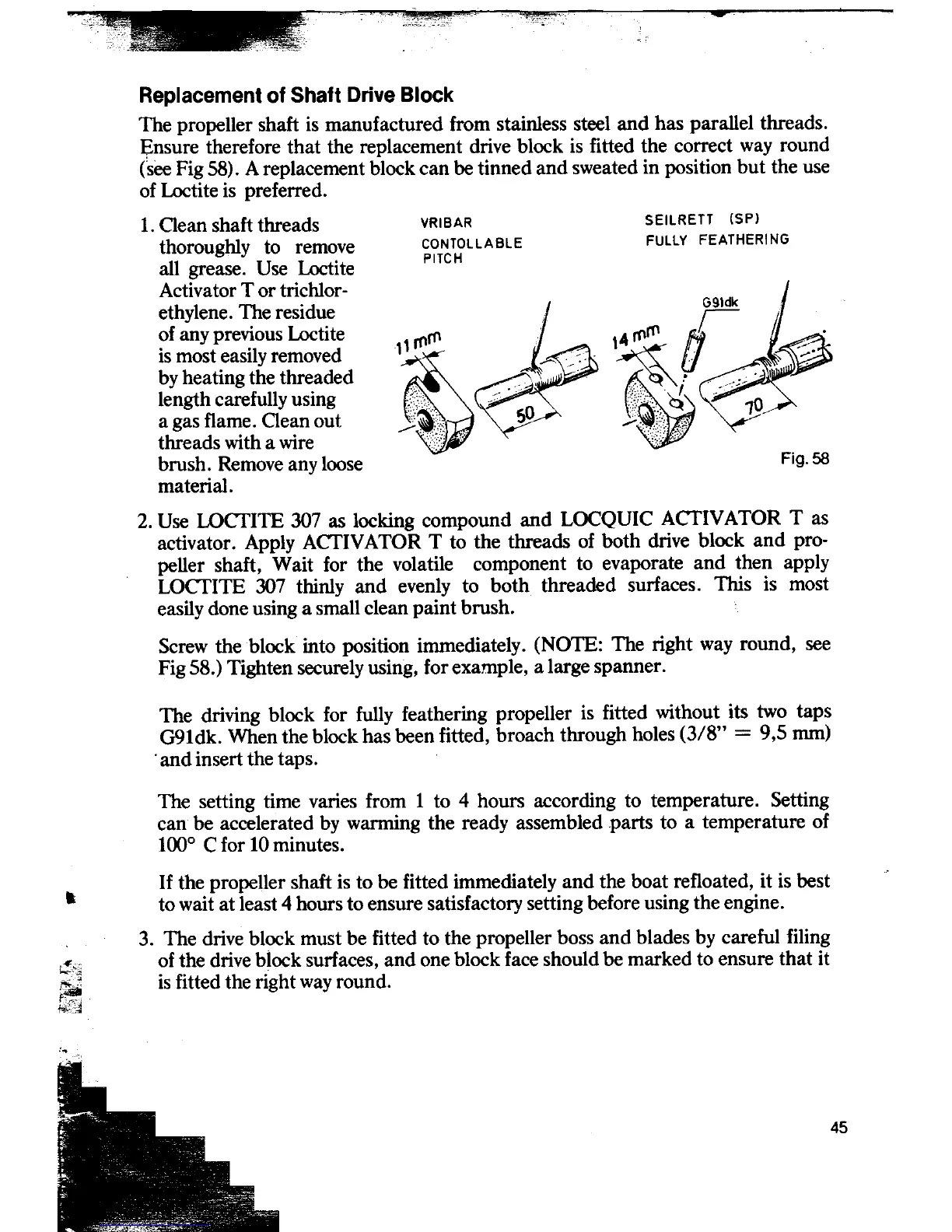

I;:nsure therefore that the replacement drive block is fitted the correct way round

(see Fig 58). Areplacement block can be tinned and sweated in position but the use

of Loctite is preferred.

1. Oean shaft threads VRIBAR SEILRETT (SP)

thoroughly to remove CONTOLLABLE FULLY FEATHERING

. PITCH

all grease. Use Loctlte

Activator T or trichlor-

iethylene. The residue G91dk

.of any pre~ous Loctite rn \4 rnrn ,/ :.- .

lsmost.easllyremoved

~j. ~-: ~ tI

~""'. by heatlng the threaded ,~ Á~ ! .:~. 1

length carefully using ,c . ' 10

a gas flame. Oean out 50

threads with a wire

brush. Remove any loose Fig. 58

material.

2. Use LOCfITE 307 as locking compound and LOCQUIC ACfIVATOR T as

activator. Apply ACfIVATOR T to the threads of both drive block and pro-

peller shaft, Wait tor the volatile component to evaporate and then apply

LOCfITE 307 thinly and evenly to both threaded surfaces. This is most

easily done using a small clean paint brush.

Screw the block into position immediately. (NOTE: The right way round, see

Fig 58.) Tighten securely using, tor example, a large spanner.

The driving block tor fully feathering propeller is fitted without its two taps

G91dk. When the block bas been fitted, broach through holes (3/8" = 9,5 mm)

. and insect the taps.

The setting time varies trom 1 to 4 hours according to temperature. Setting

can be accelerated by warming the readyassembied parts to a temperature of

100° C tor 10 minutes.

If the propeller shaft is to be fitted immediately and the boat refloated, it is best

.. to wait at least 4 hours to ensure satisfactory setting before using the engine.

3. The drive block must be fitted to the propeller boss and blades by careful filing

r!"'i of the drive block surfaces, and one block face should be marked to ensure that it

~ is fitted the right way round.

~f!~

45

Loading...

Loading...