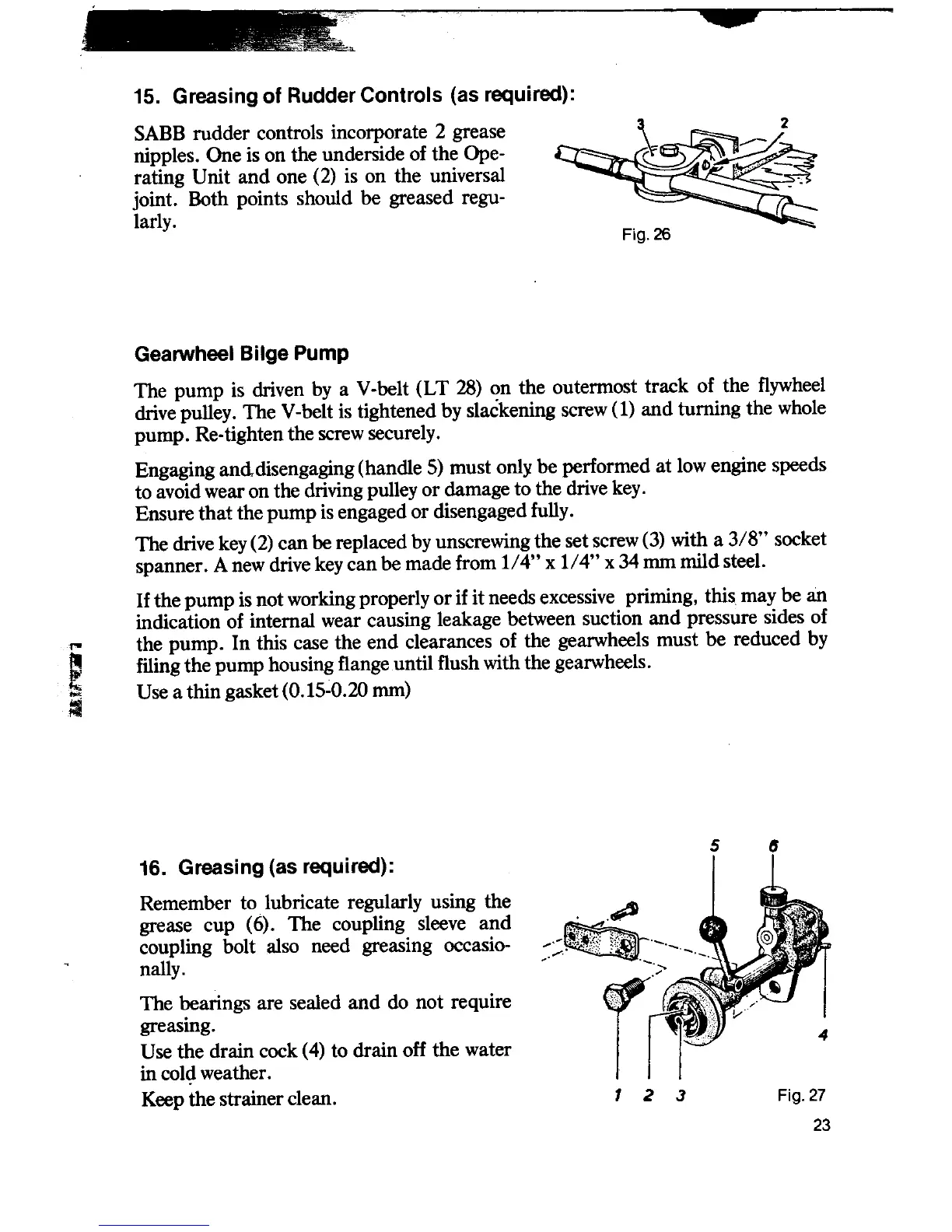

15. Greasing of Rudder Controls (as required):

SABB rudder controls incorporate 2 grease

.:~~~~~~~~ ~ )

nip'ples. ~e is on the un?erside of th~ Ope- b ~ ~

ratIng Umt and one (2) IS on the umversal 0"",- "'

joint. Both points should be greased regu- -

larly.

Fig. 26

Gearwheel Bilge Pump

The pump is driven by a V -belt (L T 28) on the outermost track of the flywheel

drive pulley. The V -belt is tightened by slaékening screw (1) and tuming the whole

pump. Re-tighten the screw securely.

Engaging anddisengaging (handle 5) must onIy be performed at low engine speeds

to avoid wear on the driving pulley or damage to the drive key.

Ensure that the pump is engaged or disengaged fully.

The drive key (2) can be replaced by unscrewing the set screw (3) with a 3/8" socket

spanner. Anew drive keycanbe made from 1/4" x 1/4" x34 mm mild steel.

If the pump is not working properly or if it needs excessive priming, tros may be a:n

indication of intemal wear causing leakage between suction and pressure sides of

~ the pump. In tros case the end clearances of the gearwheels must be reduced by

~ filing the pump housing flangeuntil flush with the gearwheels.

i Useathingasket(O.15-0.20mm)

5 &'

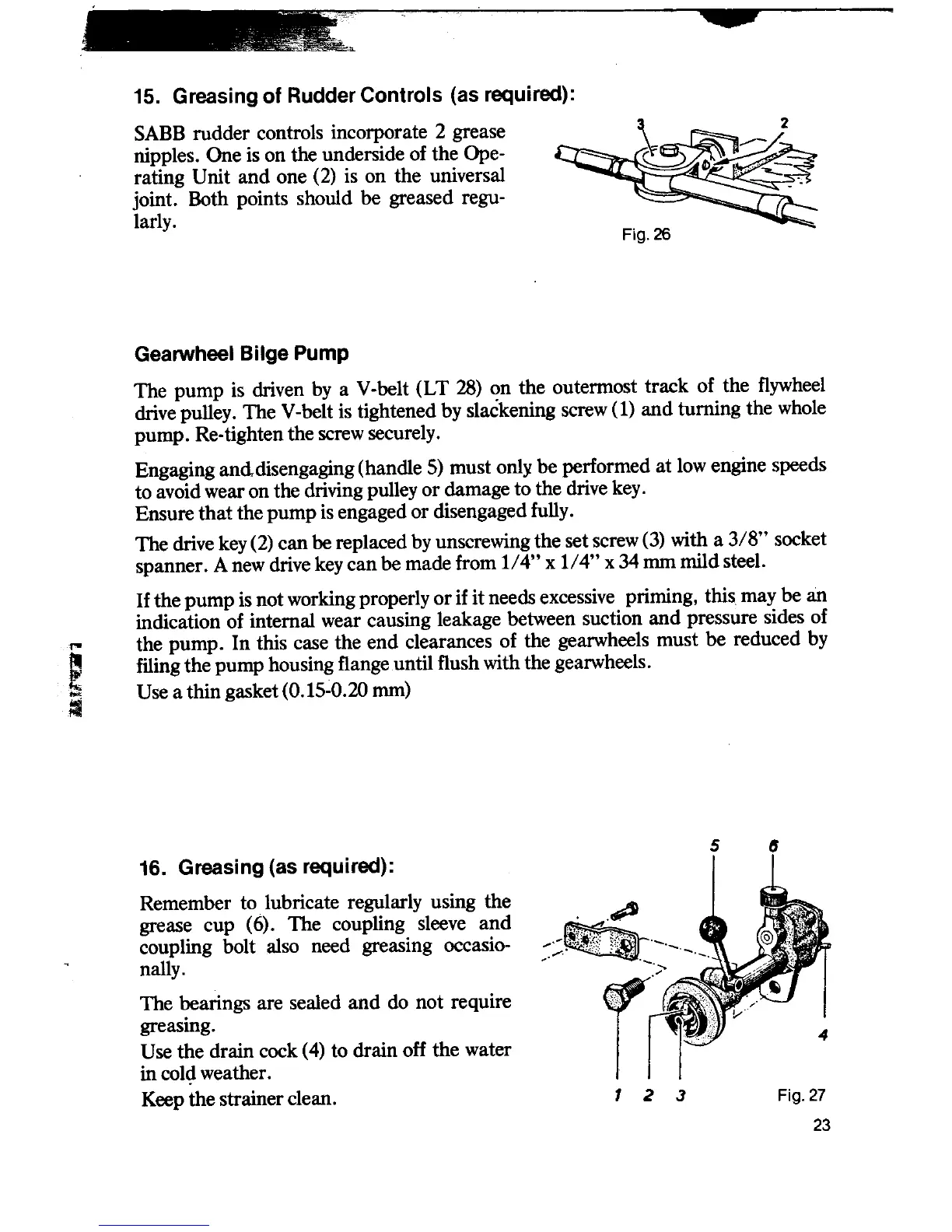

16. Greasing (as required):

Remember to lubricate regularly using the

grease cup ( 6). The coupling sleeve and

coupling bolt also need greasing occasio-~; -

nally. "',

The ~arings are sealed and do not require

~j;;;'

greasmg.

Use the drain cock (4) to drain oft the water" 4

in cold weather.

Keep the strainer clean. 1 2 3 Fig. 27

23

Loading...

Loading...