,i"t' '

':~

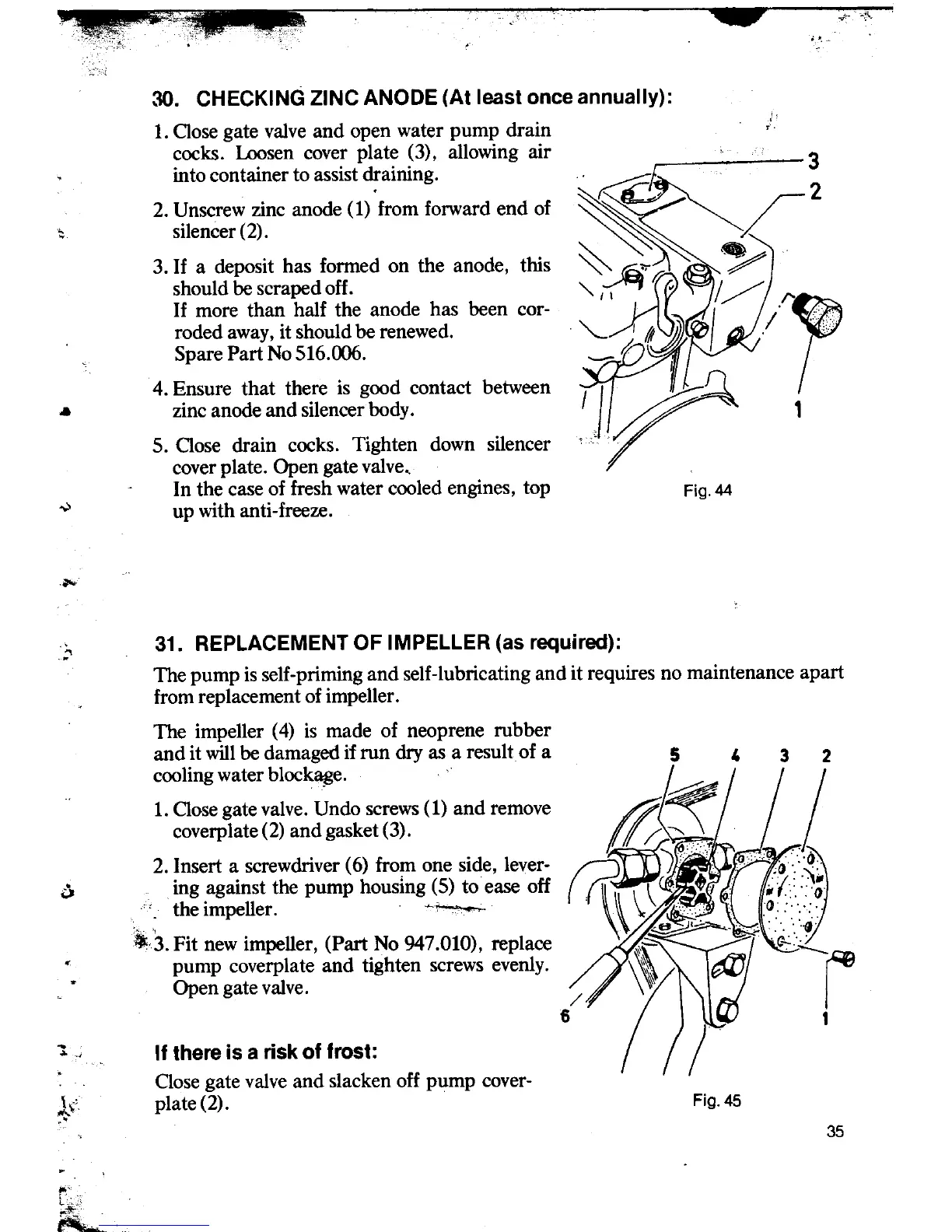

30. CHECKING ZINC ANODE (At least once annually):

i,

1. Oose gate valve and open water pump drain :

cocks. Loosen cover plate (3), allowing air ' 3

into container to assist draining., ~~~

" 2. t!nscrew zinc anode (1) from forward end of ~~

~~~~~)""'" r 2

;: sllencer(2). ~"~~ ~

3. If a deposit bas formed on the anode, this ~ ~ ~

shouldbescrapedoH. ",~

~Il" // /'1

If more than half the anode bas been cor- . cC

roded away, it should be renewed. "'- I III~» I ,/ '~;

Spare Part No 516.006. '-""" d ~

.. zmc anode and sllencerbody. 1

5. Oase drain cocks. Tighten down silencer "

cover plate. Open gate valve,

In the case of fresh water cooled engines, top Fig. 44

~ up with anti-freeze.

,..

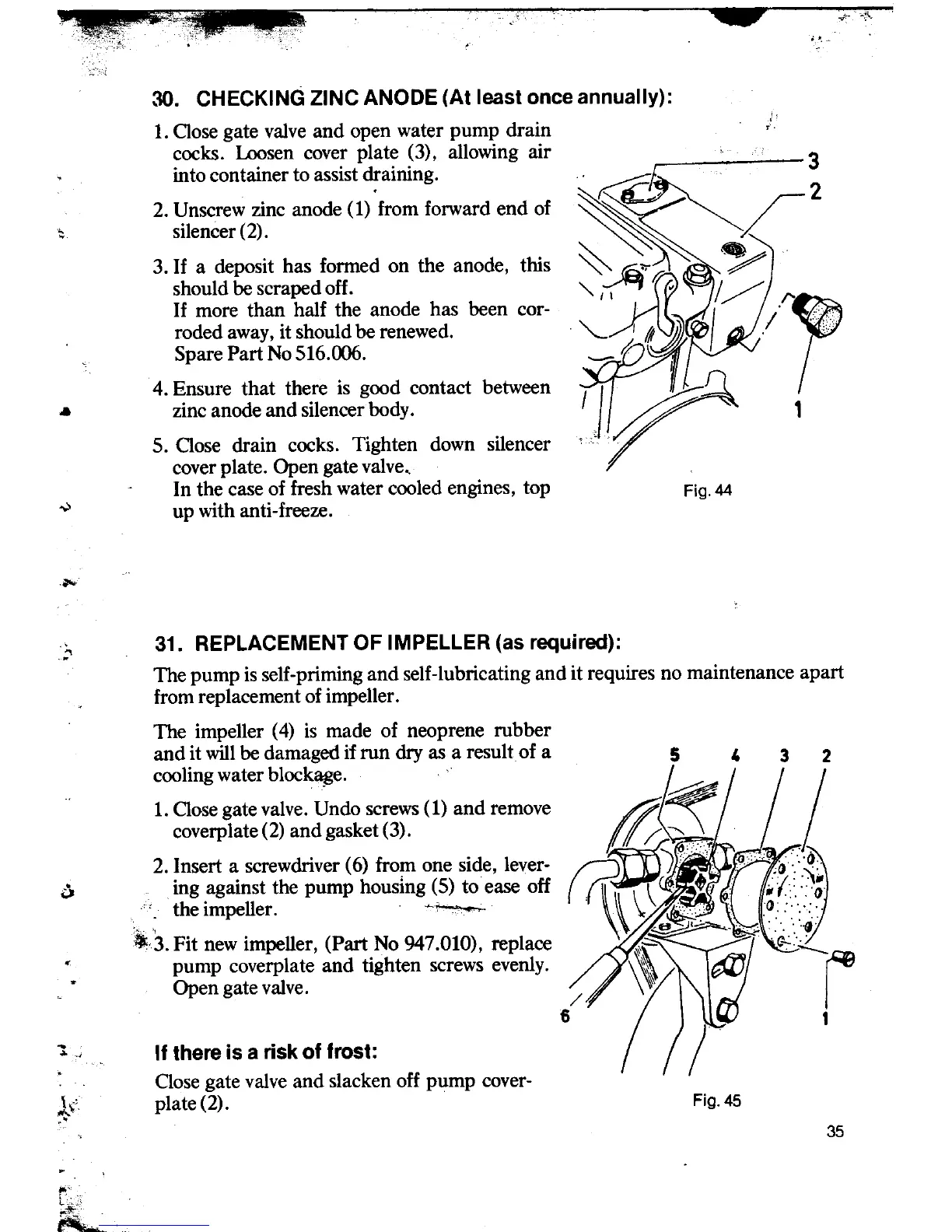

,:, 31. REPLACEMENT OF IMPELLER (as required):

The pump is self-priming and self-lubricating and it requires no maintenance apart

from replacement of impeller.

The impeller (4) is made of neoprene rubber

and it will be damaged if run dry as a resultof a 5' 2

cooling water block~e.

.

1. Oose gate valve. Undo screws (1) and remove

coverplate (2) and gasket (3).

2. Insert a screwdriver (6) from one side, lever- ~

~'; ó ing .against the pump housing (5) to ease oH :';

. thelmpeller. "'~. ':"

" , -ti

.,3. Fit new impeller, (Part No 947.010), replace '

. pump coverplate and tighten screws evenly. ~

. Open gate valve. I

6 1

"l If there is a risk ot trost:

, Oase gate valve and slacken oH pump cover-

l'" plate(2). Fig. 45

c'

35

t~,.'

~

c~

Loading...

Loading...