0 ~WfJ-""" viJSt..I!.o:.d l

--~ I

z.el? tlfrklle...~ ~Î.s~ 1c1..JIo,)',e-!("

43. REVERSE GEARBOX ~o..

The reverse gearbox works on the principle of self-adjusting CODe clutches for ahead

and astern drive. When the gear lever is moved, the gear shaft (4), together with

flange coupling (7) and propeller shaft, is moved forward for ahead drive and back-

ward for reverse.

The clutch is held engaged by the propeller thrust. To avoid a degree of clutch slip

during engagement, the clutch lever should be engaged with a light pressure. As

soon as the propeller bas begun to generate thrust, the clutch will hold in. The lever

must not touch engine casing etc.

1 The nature of this method of clutch operation makes it important that exact align-

ment between engine and propeller shaft is maintained. Any misalignment fuld

g;ive rise to clutch slip. -';..,die~ c\t. "-"o\.." e.. ~~ sc.~voe~J "ie~ tJ"~"" ~~

\0\ e'e"" ,C)"" 5"\ "',~", t.l-t. \It~y!eli"'5 Q~j"'I/&o"~).~ QIl.~ ~dd s)'~e..

If the water level in the boat is such that water may reach the oil seals in the rear

face of the gearbox, operation of the gearbox should be avoided until the boat bas

j been pumped out. This will prevent damage to the hall race on the far side of the

seals.

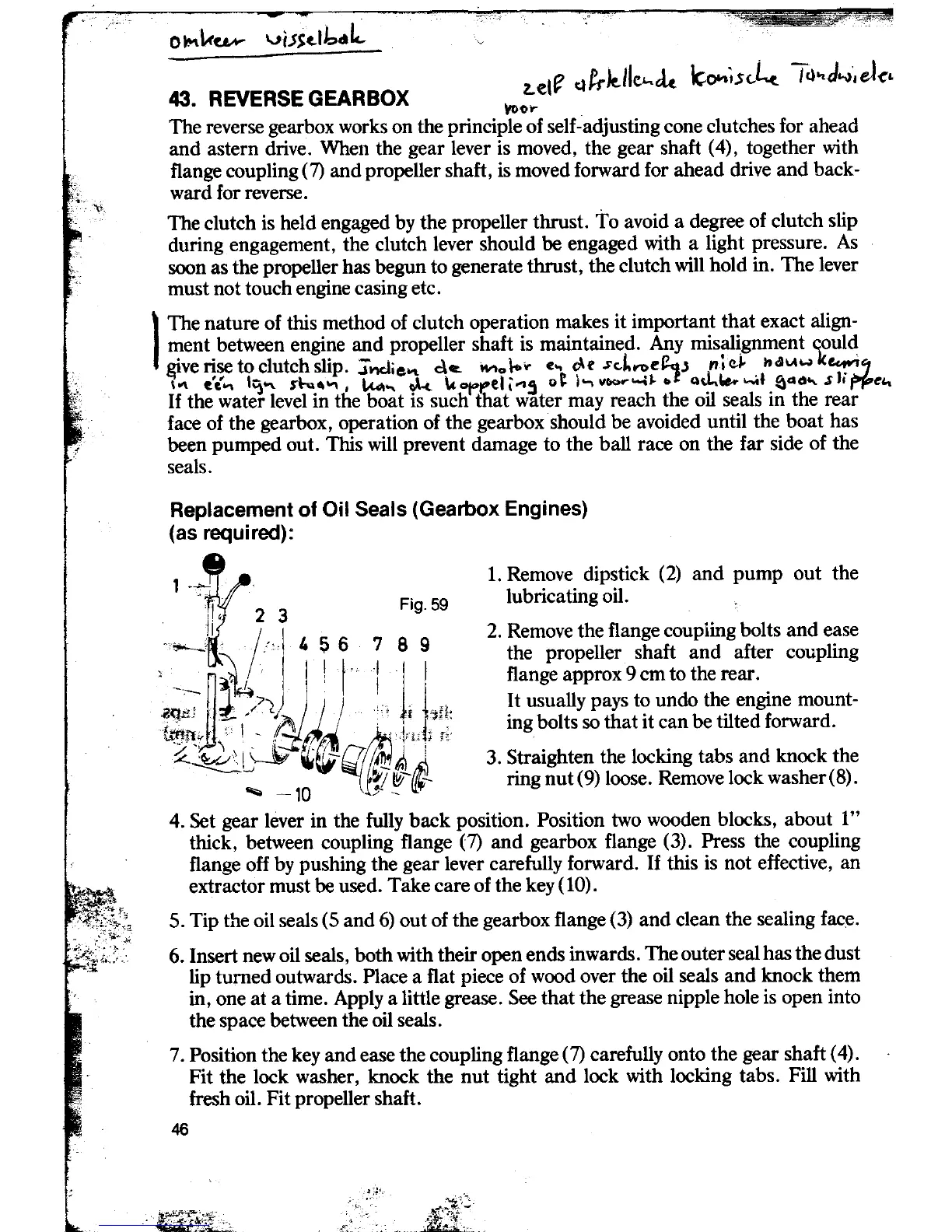

Replacement of Oil Seals (Gearbox Engines)

(as required):

1 --7:-'[ 1. Re~ove. dip~tick (2) and pump out the

", Fig. 59 lubncatlng 011.

,I. 2 3 .

)1 2. Remove the flange couplmg bolts and ease

"""-' I, I 4 5 6 7 8 9 the propeller shaft and after coupling

,~ I

~ 1 [, "

1 1 flange approx9cm tothe rear.

- ~~-j I I I

=1i 7?'b / ~ ) 'i,flij;:;~: ~~:~~~~y ~~h~:~t ~~~~~h~:e~~~~~:nt-

~~I--J~ rDfî;î!j

~~ ~ ,J 3. S.traighten the locking tabs and knock the

~ ~~~-[,-- nng nut (9) loose. Remove lock washer (8).

~ 10 !;' -

4. Set gear lever in the fully back position. Position two wooden blocks, about 1"

truck, between coupling flange (7) and gearbox flange (3). Press the coupling

flange off by pushing the gear lever carefully forward. If this is not effective, an

extractor must be used. Take care of the key (10).

!.', S. Tip the oil seals (S and 6) out of the gearbox flange (3) and clean the sealing face.

.;;

6. Insert newoil seals, both with their open ends inwards. The outer seal bas the dust

lip turned outwards. Place a flat piece of wood over the oil seals and knock them

in, ODe at a time. Apply a little grease. See that the grease nipple hole is open into

the space between the oil seals.

7. Position the key and ease the coupling flange (7) carefully onto the gear shaft (4).

Fit the lock washer, knock the nut tight and lock with locking tabs. Fill with

fresh oil. Fit propeller shaft.

46

~tk _.:i!i~-

Loading...

Loading...