'"

"; ';

CARE AND MAINTENANCE

To achieve good results in operation, it is important to give the engine the attention

recommended. Tbe following section includes general guidance, descriptive notes

and sketches to assist in routine maintenance.

If the specified maintenance is carried out correctly and at the recommended

intervals, engine deterioration will be minimised and optimum performance will be

ensured.

" ;,

MATERlALS '. Cc,

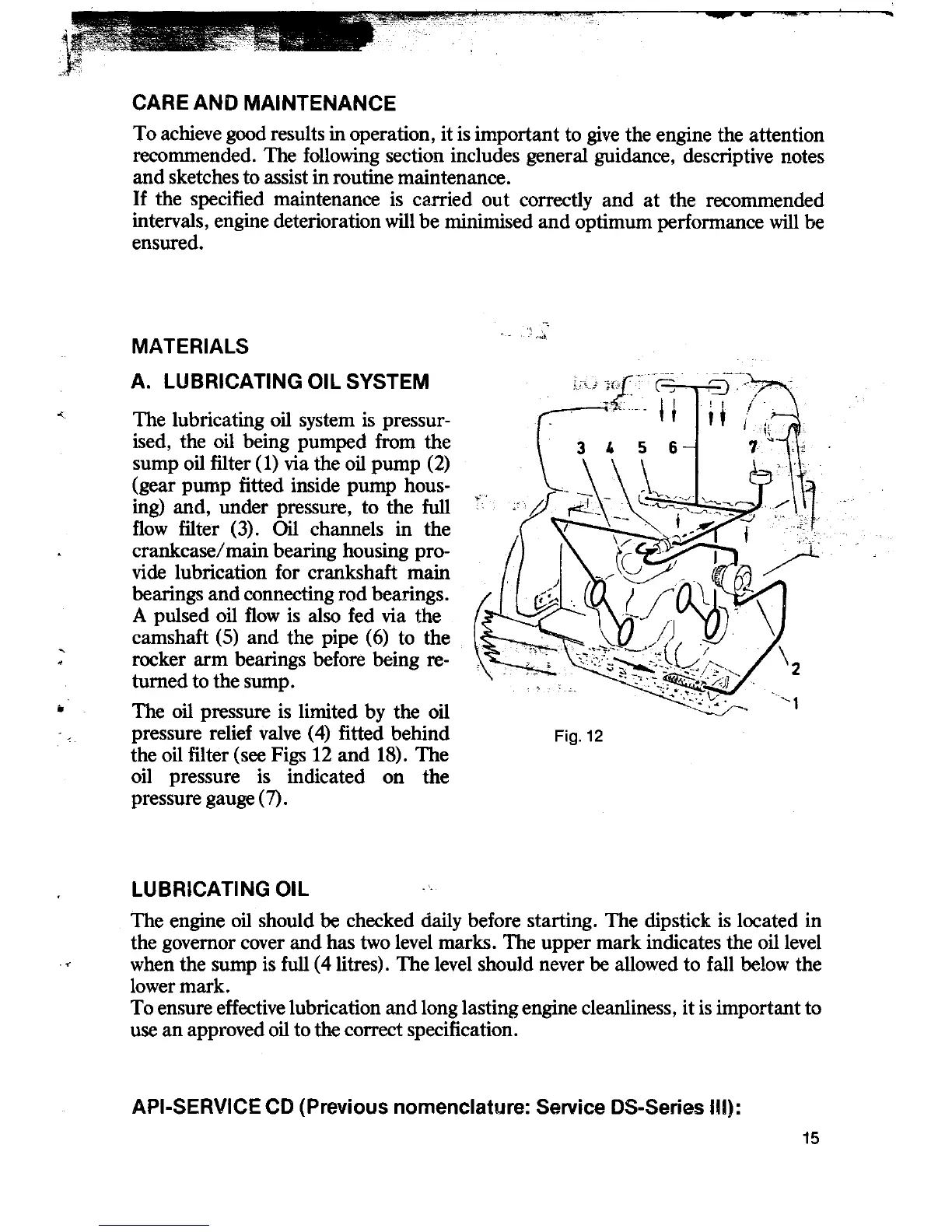

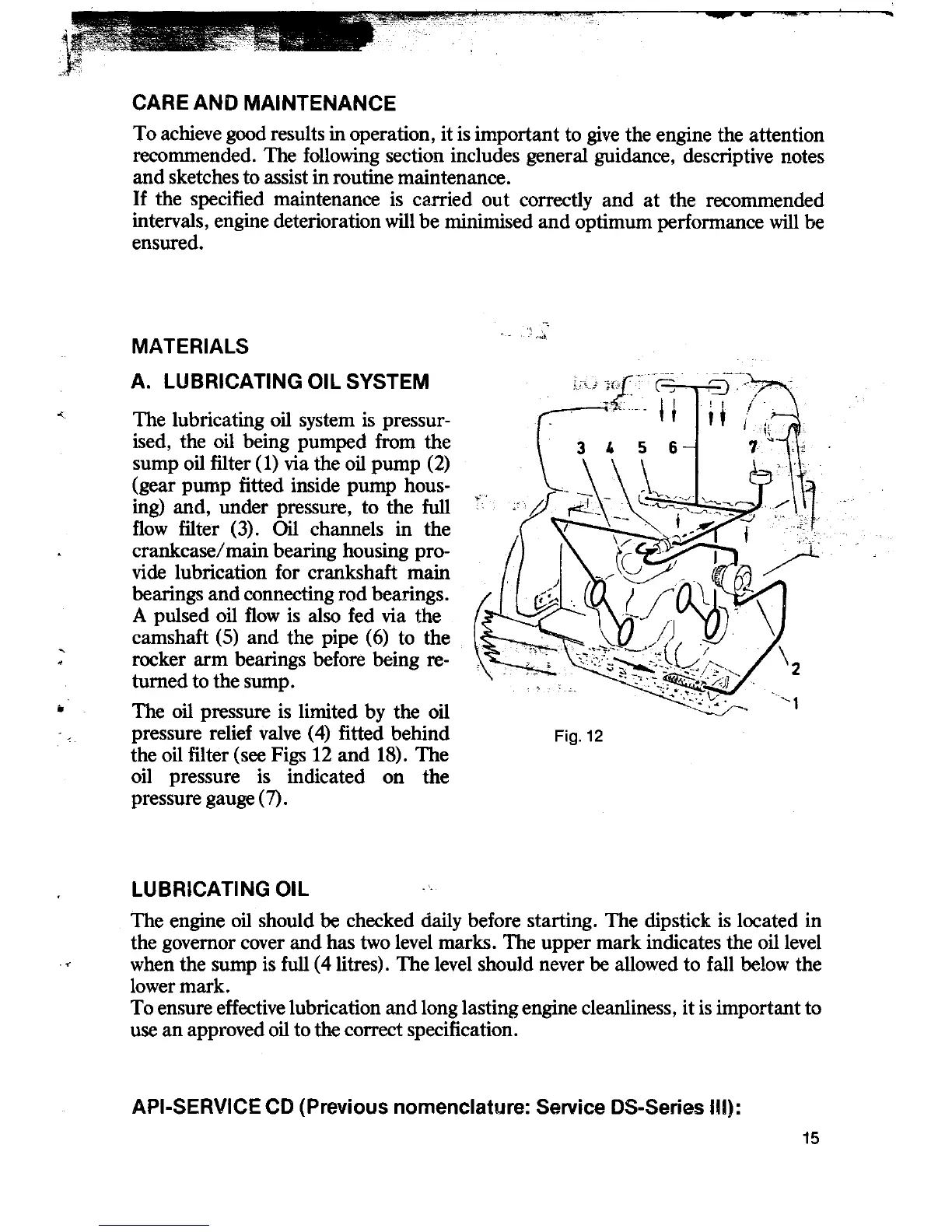

A. LUBRICATING OIL SYSTEM

'" Tbe lubricating oil system is pressur-

ised, the oil being pumped from tbe .

sump oil filter (1) via tbe oil pump (2)

(gear pump fitted inside pump hous-

ing) and, under pressure, to the fu1l

flow filter (3). Oil channels in tbe

crankcase/ main hearing housing pro-

vide lubrication for crankshaft main

hearings and connecting rod hearings.

A pulsed oil flow is also fed via the

camshaft (5) and the pipe (6) to tbe

~ rocker arm hearings before being re-

turned to the sump.

. Tbe oil pressure is limited by the oil

pressure relief valve (4) fitted behind Fig. 12

tbe oil filter (see Figs 12 and 18). Tbe

oil pressure is indicated on the

pressure gauge (7).

LUBRICATING OIL

Tbe engine oil should be checked daily before starting. Tbe dip stick is located in

the governor cover and bas two level marks. Tbe upper mark indicates tbe oillevel

. when the sump is fu1l (4Iitres). Tbe level shouJ.d never be allowed to fall below the

lower mark.

To ensure effective lubrication and long lasting engine cleanliness, it is important to

use an approved oil to tbe correct specification.

API-SERVICE CO (Previous nomenclature: Service OS-Series 111):

15

Loading...

Loading...