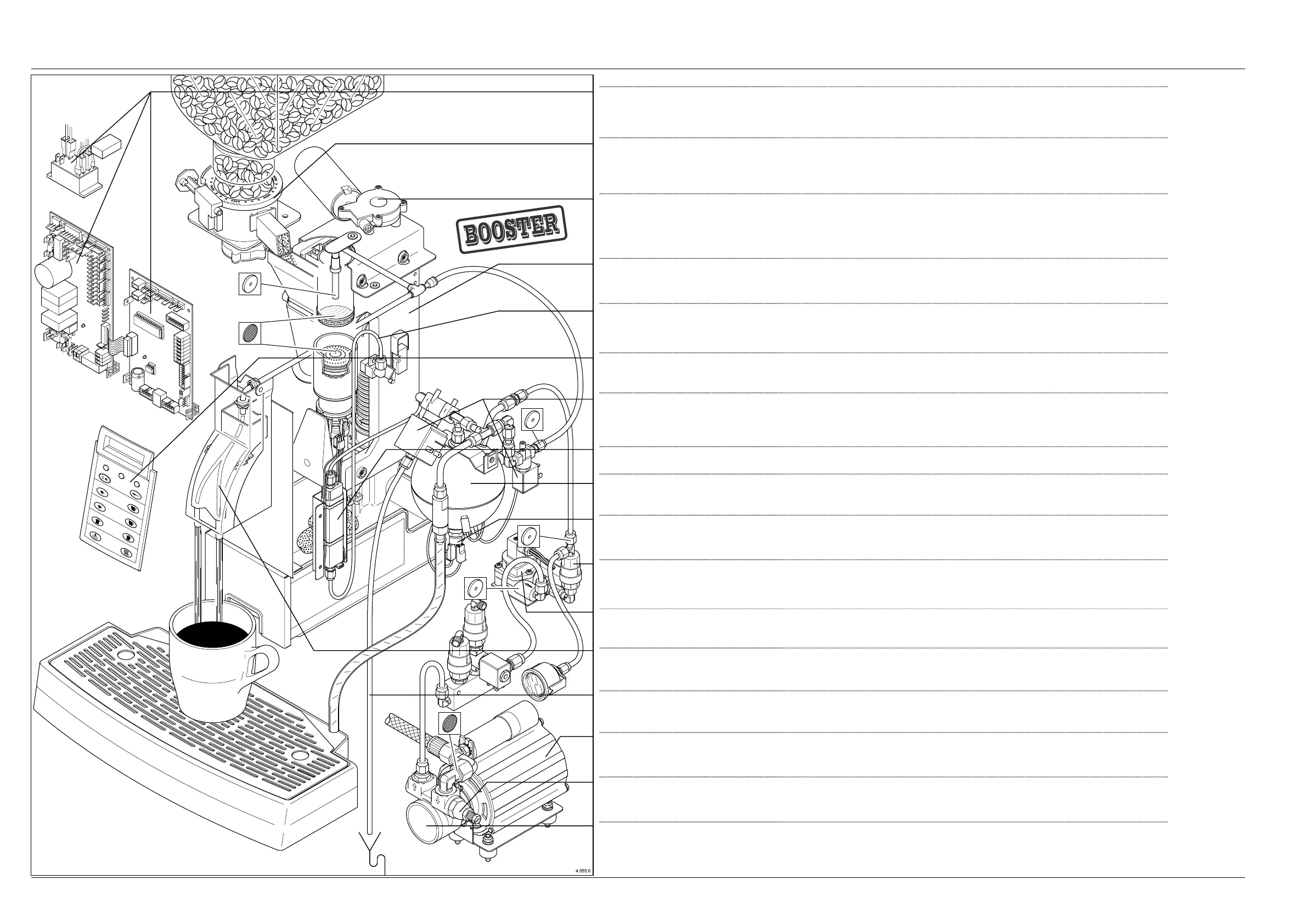

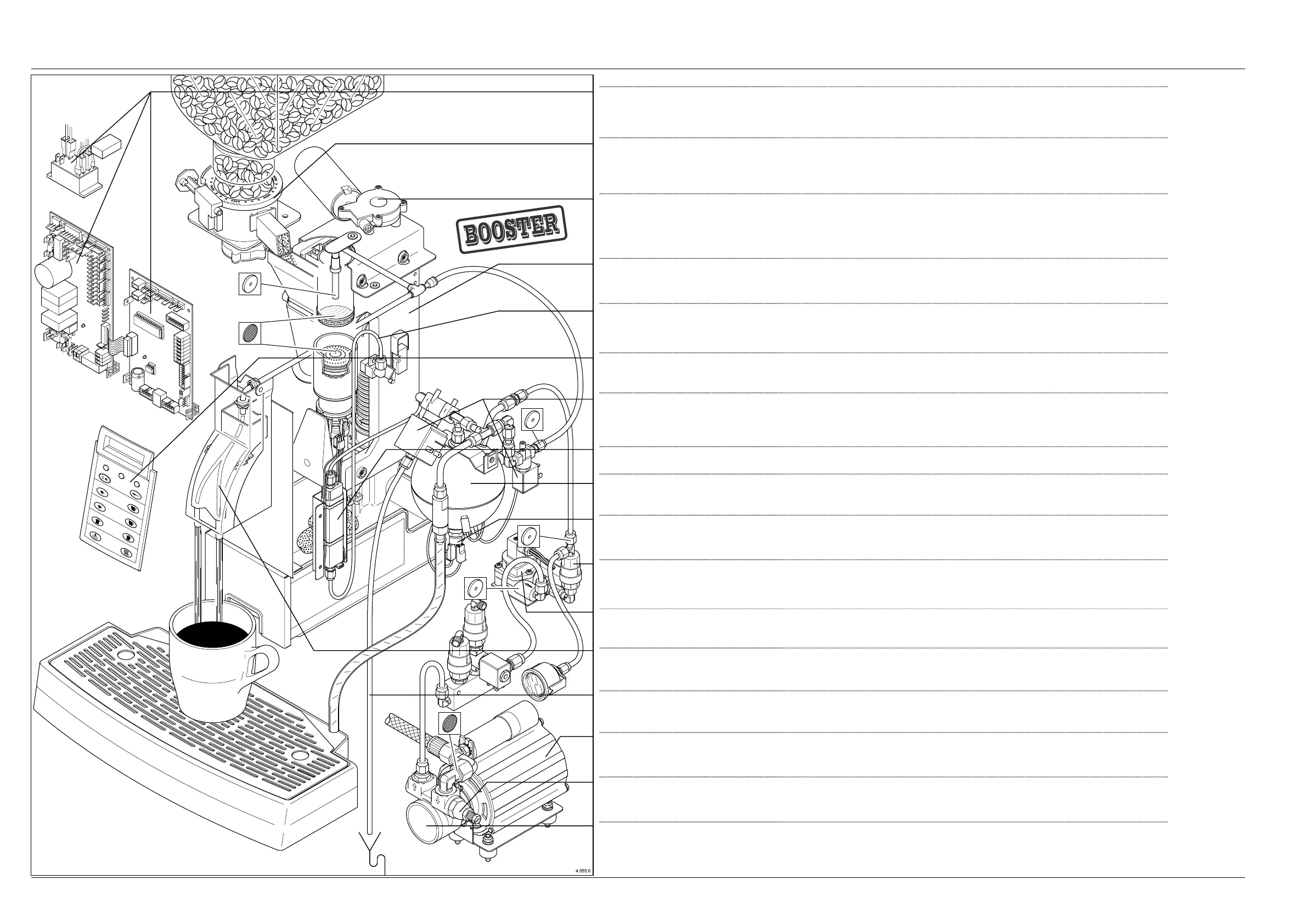

Chapter 4 Fault diagnosis

SMSO-2-02.04- 15.07.03

Power PCB / unit control system /

Power relay

Faulty fuses

Faulty relay or power transistor

Faulty EEPROM

Faulty power relay

Grinder

Grinder blade worn

Foreign bodies

Faulty motor / gear

Piston motor

Faulty motor / gear

Faulty control system / power PCB

Brewing unit

O ring defective or worn out

Inlet / outlet piston dirty

Faulty microswitch for start position

Faulty brewing cylinder, scratched

Brew pipe Clogged / dirty (coffee grease)

Bent (wrong pipe feed)

User panel

Buttons jam / foreign bodies caught in the panel

The keyboard PCB is damp

Brewing valve /

Additional water valve

Valve seat clogged and not water-tight (calcium)

Faulty coil

Faulty seal on closing element

Booster Clogged (coffee grease)

Over-temperature safety activated

Instant heater

Calcium on heating

Faulty heating

Faulty temperature sensor

Heat damage caused by over-heating

Safety thermostat

Triggered as a result of over-temperature

Faulty / faulty contacts

Non-return valve / Baffle

Calcium / not water-tight

Flowmeter

Turbine wheel jamming

Baffle clogged (calcium)

Faulty sensor

Outlet cup Clogged / dirty / faulty

Inserted at an incline

Brewing valve relief pipe Clogged / dirty (coffee grease)

Submerged in siphon in water

Motor Faulty capacitor

Faulty RC module

Control set O-ring defective

Too much / not enough grease

Rotary-vane type pump Clogged (calcium)

Worn out (dry running)

Faulty bearing (noisy)

Loading...

Loading...