Chapter 5 Dismantling components

SMSO-2-02.05- 15.07.03 167

5.5.3 Brewing unit

For safety information see the section

entitled “Safety Regulations”

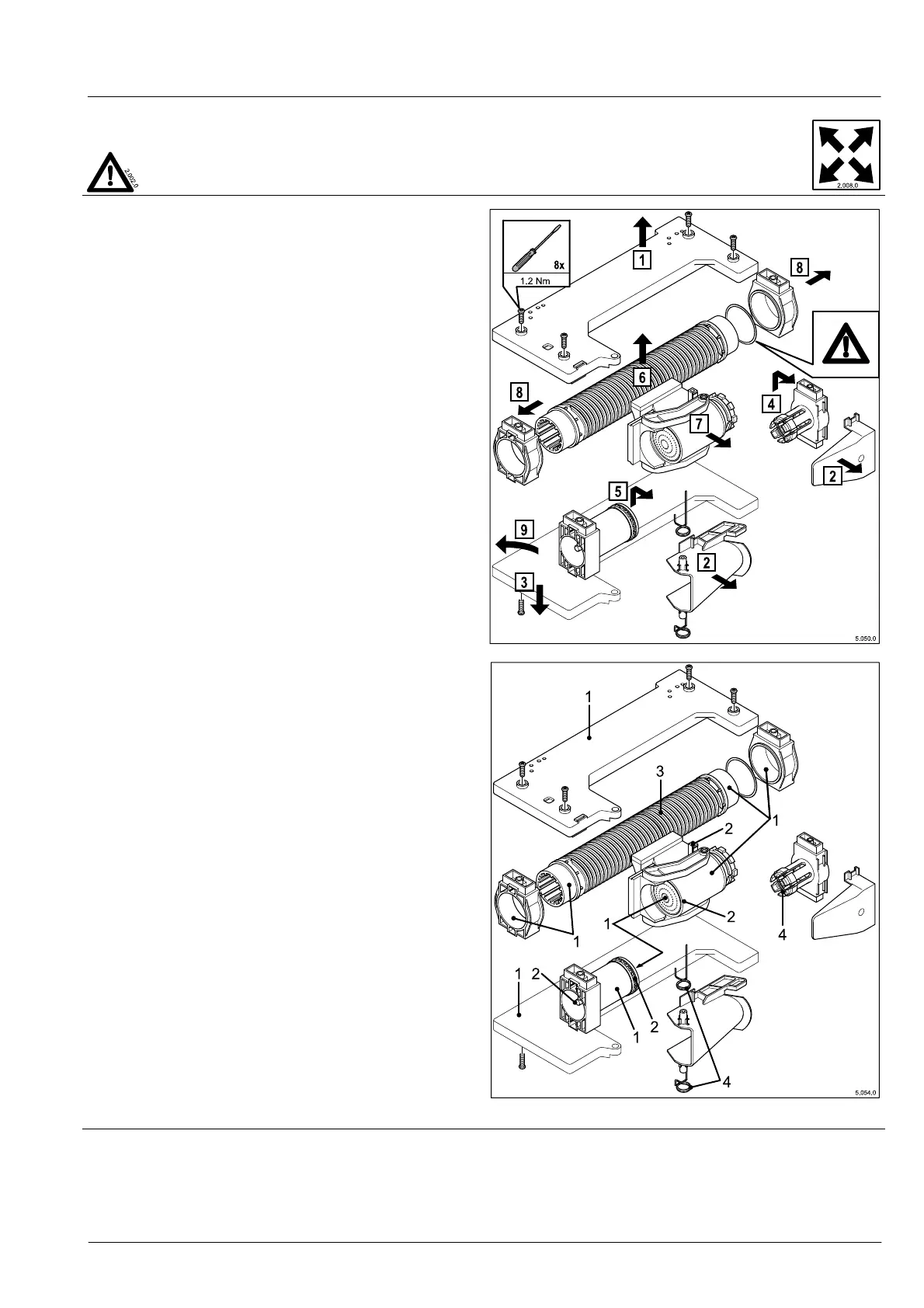

Disassemble the brewing unit

Preparation

Dismantle the brewing unit

1. Screw out the screws on the side panel ; lift off the side

panel, hold down the spring on the funnel.

2. Pull out the funnel with the two springs and the protec-

tion for friction plunger out of the bearings.

3. Unscrew the screws on the left-hand side panel; place

the entire brewing unit on the left-hand side panel, and

then remove the individual components.

4. Take the friction plunger out of the bearing on the side

panel

5. Take the outlet piston out of the bearing on the side

panel

6. Take the spindle with bearings and brewing cylinder /

lower piston out of the bearings on the side panel.

7. Pull the lower piston / brewing cylinder with stripper off

the spindle.

8. Take the upper and lower spindle bearings off the spin-

dle; gentle remove the lower start-up disk

9. Place the left-hand side panel to one side

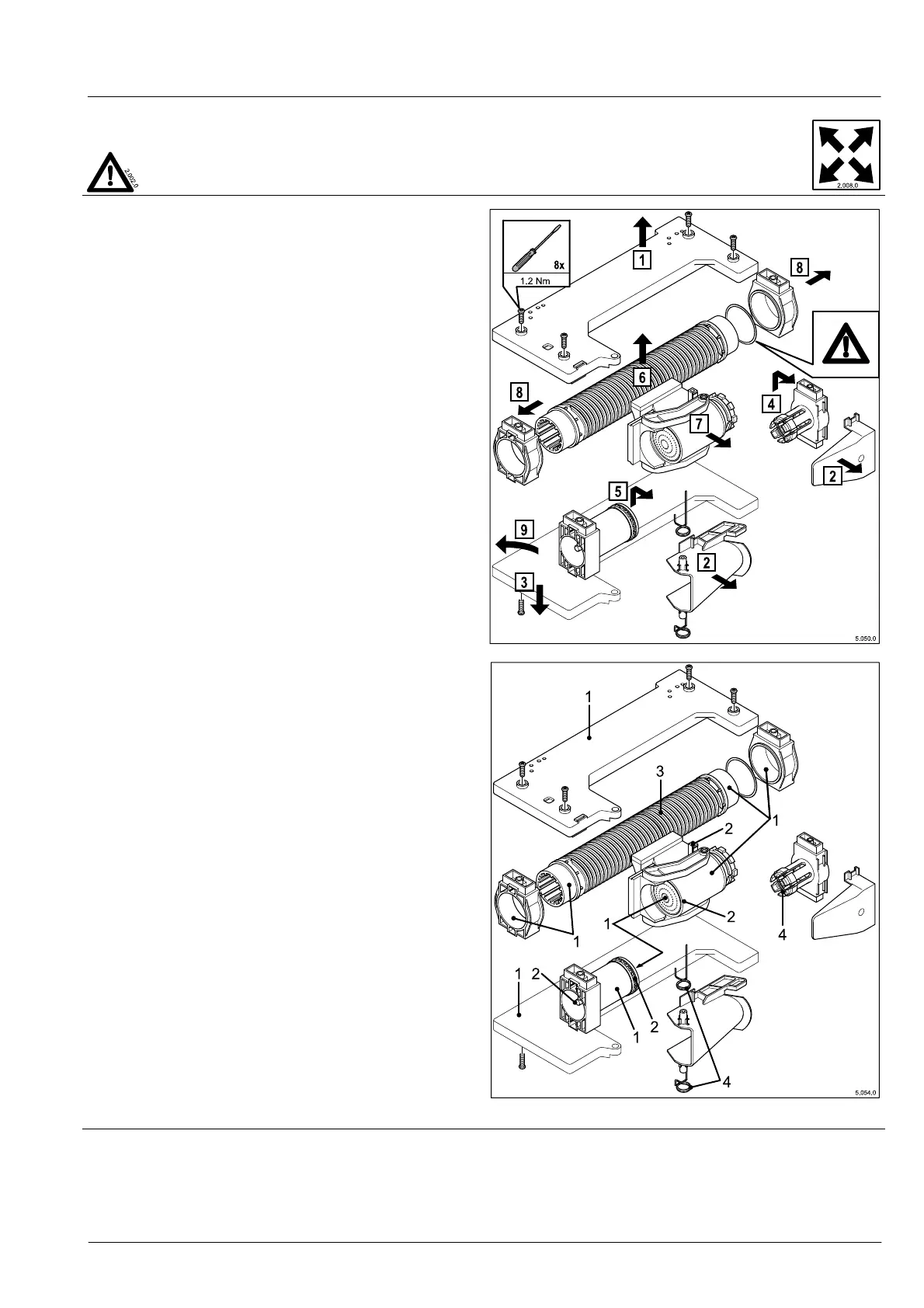

Checks:

All the components of the dismantled brewing unit must be

subjected to a thorough inspection:

1. Plastic parts: for cracks, broken (off) parts, traces of

wear (scoring, marks, the effects of heat and/or chemi-

cals) surface roughness on bearings

2. Lower piston / outlet piston Sieve / baffles with calcium

deposits or clogged with coffee extracts

3. Spindle: Eruptions, damage to bearings, start-up disk

4. Funnel, friction piston: Springs deformed or weak

This intensive check will indicate whether the brewing unit

should be replaced as a complete unit, or whether individual

parts need to be replaced.

Exchanging / repairing sub-assemblies

Lower piston Replace the O-ring

Outlet piston Replace the O-ring

Brewing cylinder Replace the stripper

Loading...

Loading...