Chapter 5 Dismantling components

SMSO-2-02.05- 15.07.03 137

5.4.6 Booster

For safety information see the section entitled

“Safety Regulations”

Preparations

Dismantle the bean container

Dismantle the cup plate

Move the dispenser carriage fully upwards

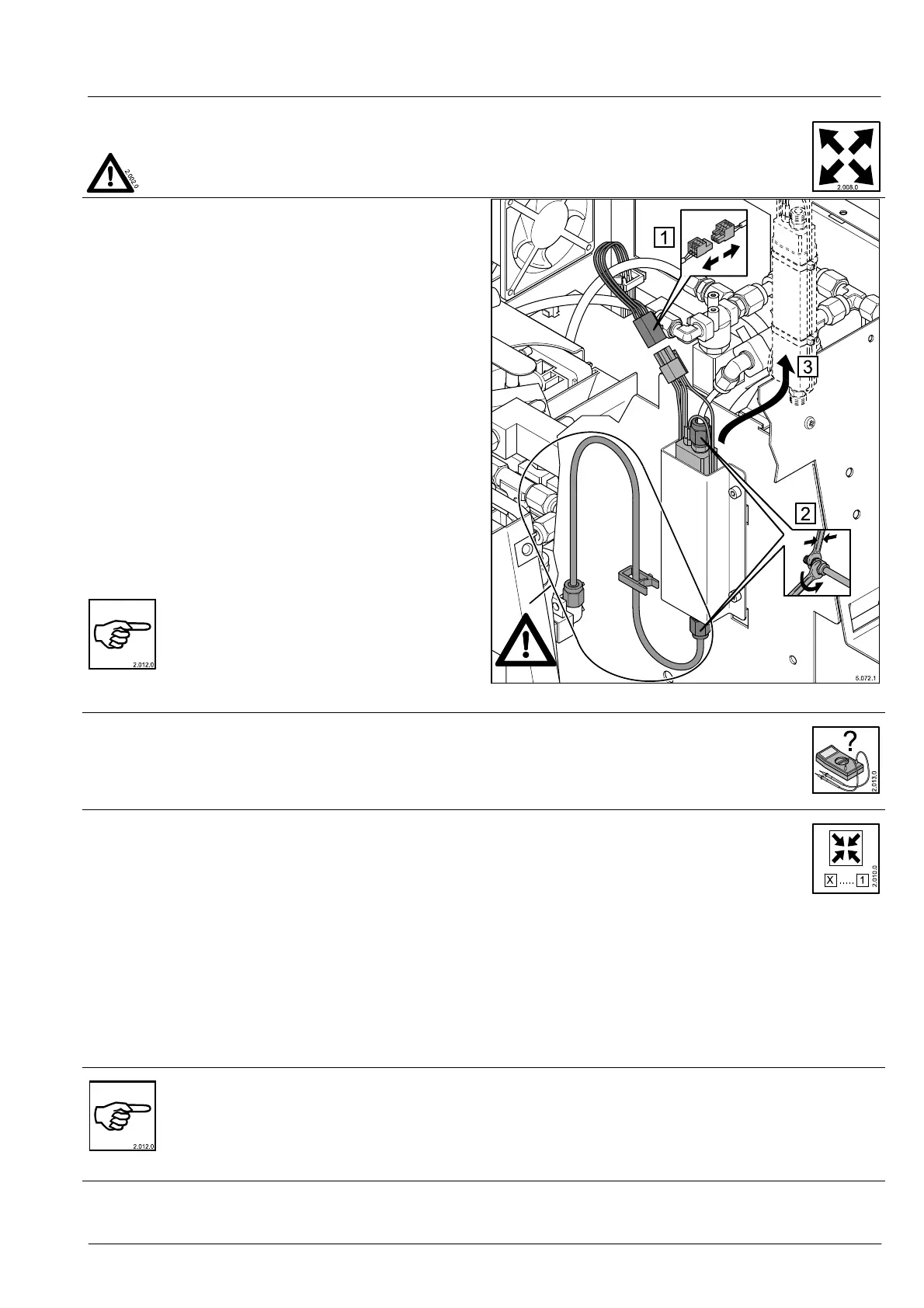

Dismantling

1. Disconnect the plug-in connection

2. Loosen the union nuts on the brewing pipes. Keep a

steady hold on the plastic screw connections on the

booster.

Caution! do not bend the short tube.

3. Pull the booster out of the holder

Service

Carefully clean the water flow hole of contamination (use

a suitable brush; BE CAREFUL, do not scratch the

hole!)

If it is heavily soiled, the booster must be completely

replaced.

In the event of a fault, the booster must al-

ways be replaced as a complete unit. No

components of the unit (heating / over-

temperature fuse etc.) should be replaced

separately.

Electrical check

See section entitled “Control system diagram, Booster”

Installation

Carry out assembly in reverse order to the dismantling

procedure.

Assembling the brewing pipe between booster and

brewing unit

Connect the tube to the booster

Move the brewing piston to the uppermost position

(system test, move brewing piston…)

Check both bends on the brewing pipe (no kinks);

and then

Introduce the brewing pipe into the plastic holder

Move the brewing piston to the uppermost and bot-

tommost positions and again check that the brew-

ing pipe has no sign of any kinking.

The two brewing pipes must be connected very carefully. The booster-brewing unit pipe must lie cleanly on the

supporting wall and it must not prevent any movement of the brewing unit.

Be sure that you do not bend the pipes. Before assembly, submerge the brew pipe for 2 to 3 minutes in 50 to

60°C hot water until it can be shaped more easily.

Loading...

Loading...