Chapter 3 Functional descriptions

SMSO-2-02.03- 15.07.03 85

3.4.9 Rinsing the milk – milk foam pipes

(refrigerator with cold water rinse)

.......... 01.04.2002

.......... Serial no. 505123

Product serving:

Requirements:

Notes

Prior events: no milk or milk foam has been served for at least two minutes. During the rinsing process

product servings are blocked.

Machine in operation, heated up, programmed to serve milk products.

Refrigerator in operation

A small amount of steam is required for the rinse operation. The full process of steam generation is not

described in detail here (see section entitled “Steam system (milk drinks)”). See the section entitled

“Components” in this chapter for detailed functional descriptions of individual components (e.g. pump

with bypass).

During the rinse process, the milk and milk foam pipes are rinsed together. Both steam outlet valves are

also activated accordingly.

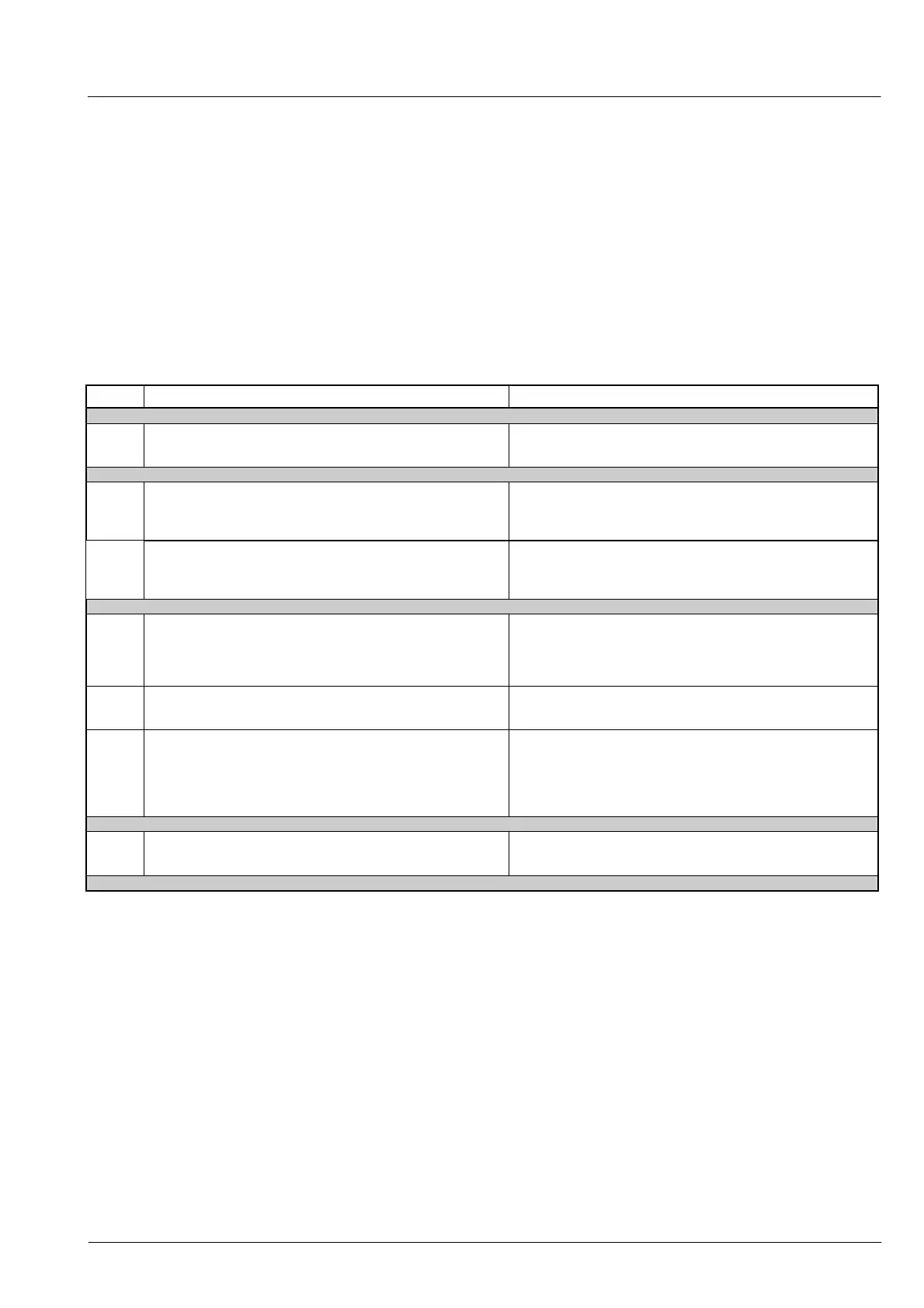

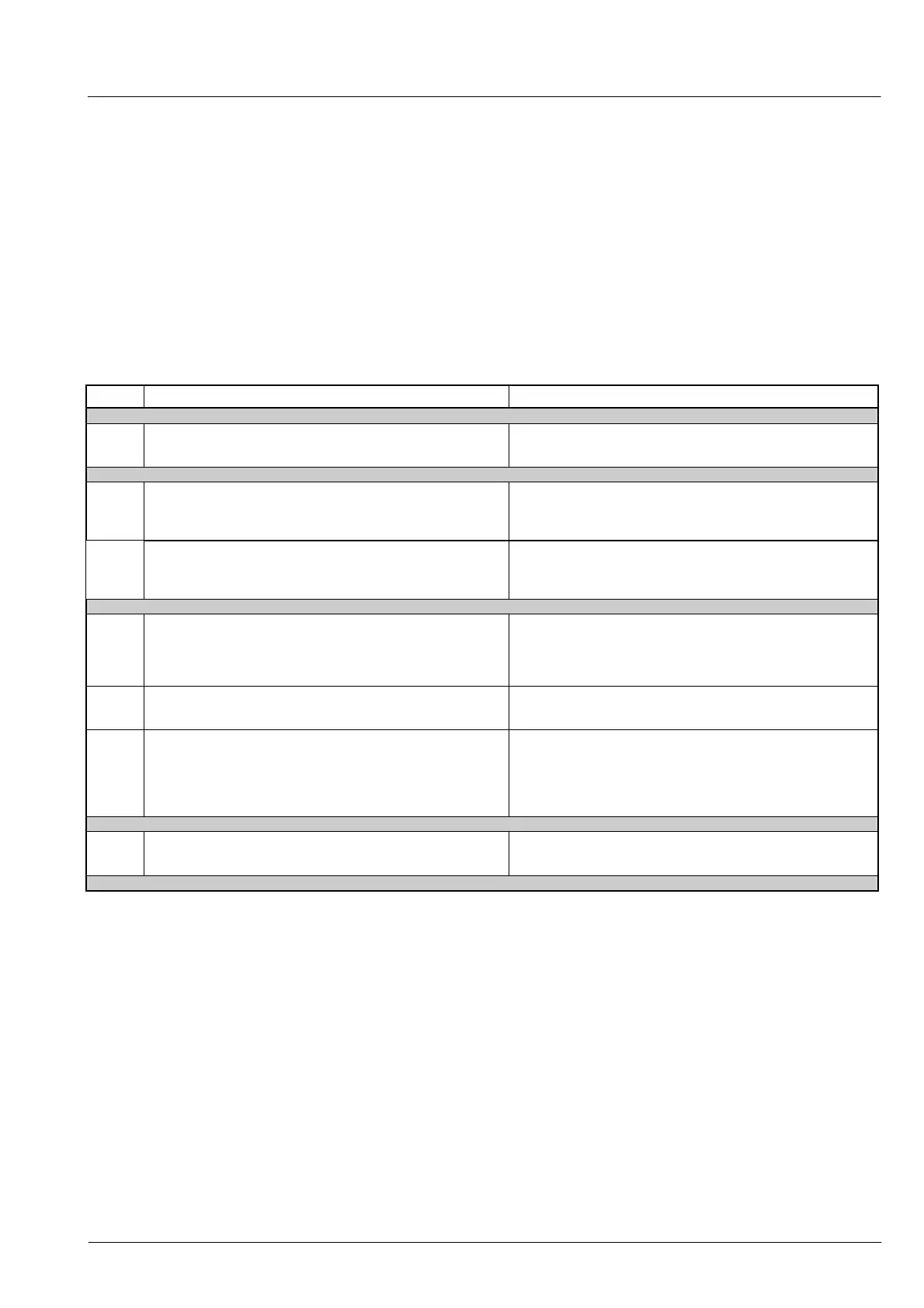

Process

step

Control system (electronic/electrical) Hydraulic system

Product selection

The control system’s monitoring function (timer) has ascertained

that no milk or milk foam serving has been made for at least two

minutes. The milk pipes must be rinsed.

Pinch the milk suction pipes

1 The solenoid valve for the water / squeeze cylinder opens (power

transistor connects through).

The solenoid valve opens and water flows into the water cylinder.

The suction pipes for milk and for milk foam are pinched, so that

no rinse water can flow into the milk container.

2 Solenoid valves for water rinsing open (power transistors connect

through)

After the set time, the control systems switches off the two sole-

noid valves. Water rinsing ends.

Solenoid valves open. The milk and milk foam pipes are rinsed

with water. The rinsing water flows into the drip tray.

Milk pipes emptied and foamer head rinsed out

3 The steam outlet valve for milk and milk foam open (power tran-

sistors connect through)

Solenoid valves open and steam flows through the injector noz-

zles into the foamer head. Due to the under-pressure in the injec-

tor nozzles the contents of the milk or milk foam pipes is sucked

away from the refrigerator. The rinsing water flows into the drip

tray.

4 Solenoid valve for the water / squeeze cylinder switches off Solenoid valve closes; water / squeeze cylinder releases the milk

suction pipes and milk can now be extracted from the milk con-

tainer.

5 After approximately 0.2 seconds:

Lifting magnet on ventilation valve switches on (power transistor

connects through)

The lifting magnet opens the ventilation valve. The pipes to the

foamer head are sucked empty through the steam output from the

injector nozzles. The milk foamer housing is rinsed out. The rins-

ing water flows into the drip tray.

The milk that had been sucked up as far as the ventilation valve

now flows back into the milk container.

Rinse procedure ends

6 Solenoid valves switch off

Steam outlet operation

Ventilation valve

The steam outlet operation ends; the milk and milk foam pipes

and the milk foamer head have been rinsed clean.

The ventilation valve closes the milk and milk foam pipes.

See “Steam output (milk drinks)” for heating the steam generator, topping up the steam generator

Loading...

Loading...