Chapter 3 Functional descriptions

SMSO-2-02.03- 15.07.03 33

3.2.5 Grinder

In the grinder the coffee beans are ground through a three

level grinding unit to become fresh ground coffee. As the cof-

fee beans are crushed, much of the mechanical energy is

converted into heat (friction). The components of the grinder

heat up and in “continuous operation” this heat transfers to the

ground coffee. If the ground coffee gets too warm, the quality

of the coffee can deteriorate. It is therefore very important that

the grinder blades are always in good condition and that the

beans are broken up efficiently and not crushed.

(NOTE: At an average grinding time of 4.5 seconds per coffee,

80,000 cups will signify approximately 100 operating hours).

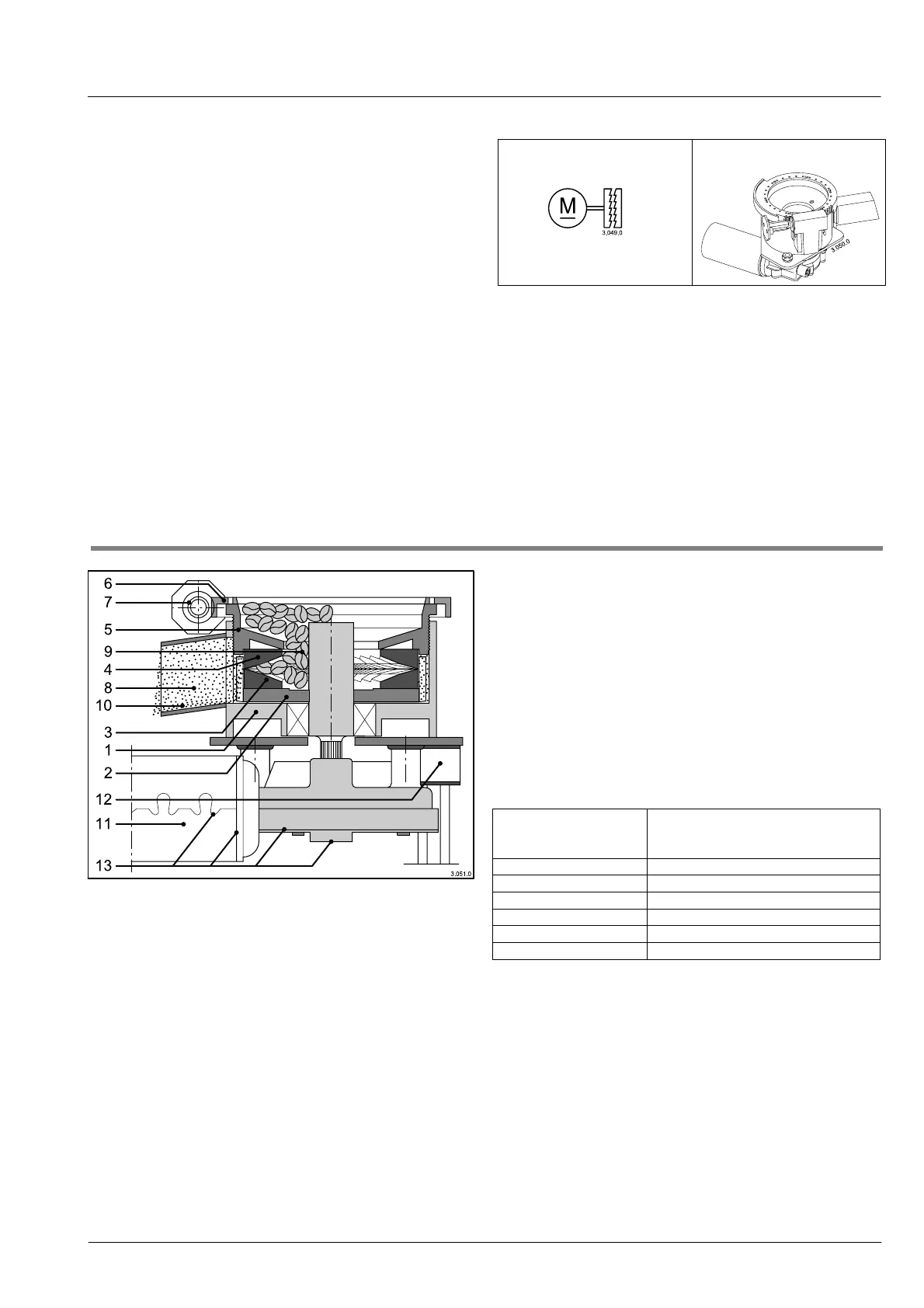

Functional description

The two grinder blades are mounted horizontally. The lower

grinder blade sits on a star shaft at the base of the grinder

housing, and it is driven by means of a worm gear motor. The

upper grinder blade is mounted with a threaded bush so as to

be adjustable axially and does not rotate.

By adjusting the upper grinder blade axially the air gap be-

tween the two grinder blades can be adjusted very accurately.

This air gap defines the grain size of the ground coffee, what

is known as the grinding degree.

The grinding degree setting (the distance between the grinder

blades) is made manually on a “worm gear” which engages on

every quarter turn, and is thus secured against coming loose

(losing its setting). The powder (ground coffee) is discharged

into the powder outlet through four cams attached evenly

around the circumference of the star shaft. A wire at the end of

the powder outlet ensures that the fresh ground coffee falls

into the brewing unit powder inlet in a controlled fashion.

The control system monitors the operating status of the

grinder via the motor current . A grinder running empty, bean

container empty (=low grinding resistance) or foreign bodies in

the grinder (very high grinding resistance) etc. will affect the

current consumption by the motor, which is detected and the

grinder switched off. A relevant error message appears on the

display.

Grinder

1 Grinder housing

2 Star shaft

3 Lower grinder disk

4 Upper grinder disk

5 Upper part of grinder

6 Grinding degree disk (setting scale)

7 Worm gear

8 Powder outlet

9 Coffee beans

10 Ground coffee (coffee powder)

11 Motor / gear

12 Rubber / metal buffer

13 Visual check during service

Technical data

Nominal voltage: 24 V DC

Operating voltage: 30-36 V DC

Operating current: 5-6 A

Idle current: 1-1.6 A

Current when “grinder empty”: < 1.45 A (corresponds to

value 50 in the program-

ming system)

Current when “grinder blocked”: <8A for 1 second or

<8.4A for 0.2 seconds

Grinding degree setting

Drawing symbol

Illustration

Grinding degree setting

Number of clicks of the grinding

degree disk (take note of the directi-

on of rotation).

+/- 10 % 5

+/-20 % 10

+/- 30 % 15

+/- 40 % 20

+/- 50 % 25

over 50% Readjust the grinding degree disk

Loading...

Loading...