Chapter 3 Functional descriptions

SMSO-2-02.03- 15.07.03 31

3.1.8 Calcium (limescale)

Besides very low quantities of minerals tap water often con-

tains a high proportion of bi-carbonate. Depending on the

proportion involved the water is designated “soft” or “hard”.

When the water heats up these bi-carbonates turn into cal-

cium deposits, i.e. limescale, particularly inside the instant

heaters and the steam elements, and also inside the pipes

and valves. The calcium deposits lead to a poor quality of

energy transfer, and thus to an increase in power consump-

tion, hard seals and gaskets, and shorter service life of com-

ponents. And besides the encrusted deposits, there are often

calcium particles floating freely in the water. These free parti-

cles of calcium can cause a wide variety of faults (reduction in

pipe cross-sections, clogging of valve seats, baffles and fil-

ters).

In order to make a high quality coffee, the water must contain

a certain amount of calcium. If the proportion of calcium is too

low the coffee’s aroma cannot develop fully, the brewing time

becomes longer, and the milk in the coffee coagulates, the

cream becomes flat and unstable. (see “water specifications”).

However, the problem of calcium is not solved by removing all

the calcium from the water with a water softening system. It is

equally unfavourable, if the water is processed through a wa-

ter softener, to have a pH value that is too high (acid) or too

low (alkaline). These properties cause increased corrosion in

pipes and thus an increased risk of leaks.

For this reason service technicians must always be aware of

the latent hazards and problems caused by calcification and

calcium damage.

When maintenance work is carried out, components with de-

posits of calcium can be treated in two ways:

1. The part is replaced. Some components must be replaced

when they are covered with calcium deposits, with others

it is not worth the time involved in decalcifying, or they

may not work efficiently after the decalcifying operation.

The instant heater and the steam generator must never

be decalcified.

2. The component is decalcified: There are relatively few

components that may be decalcified. The table below

shows, which parts these are; the information in the table

is final.

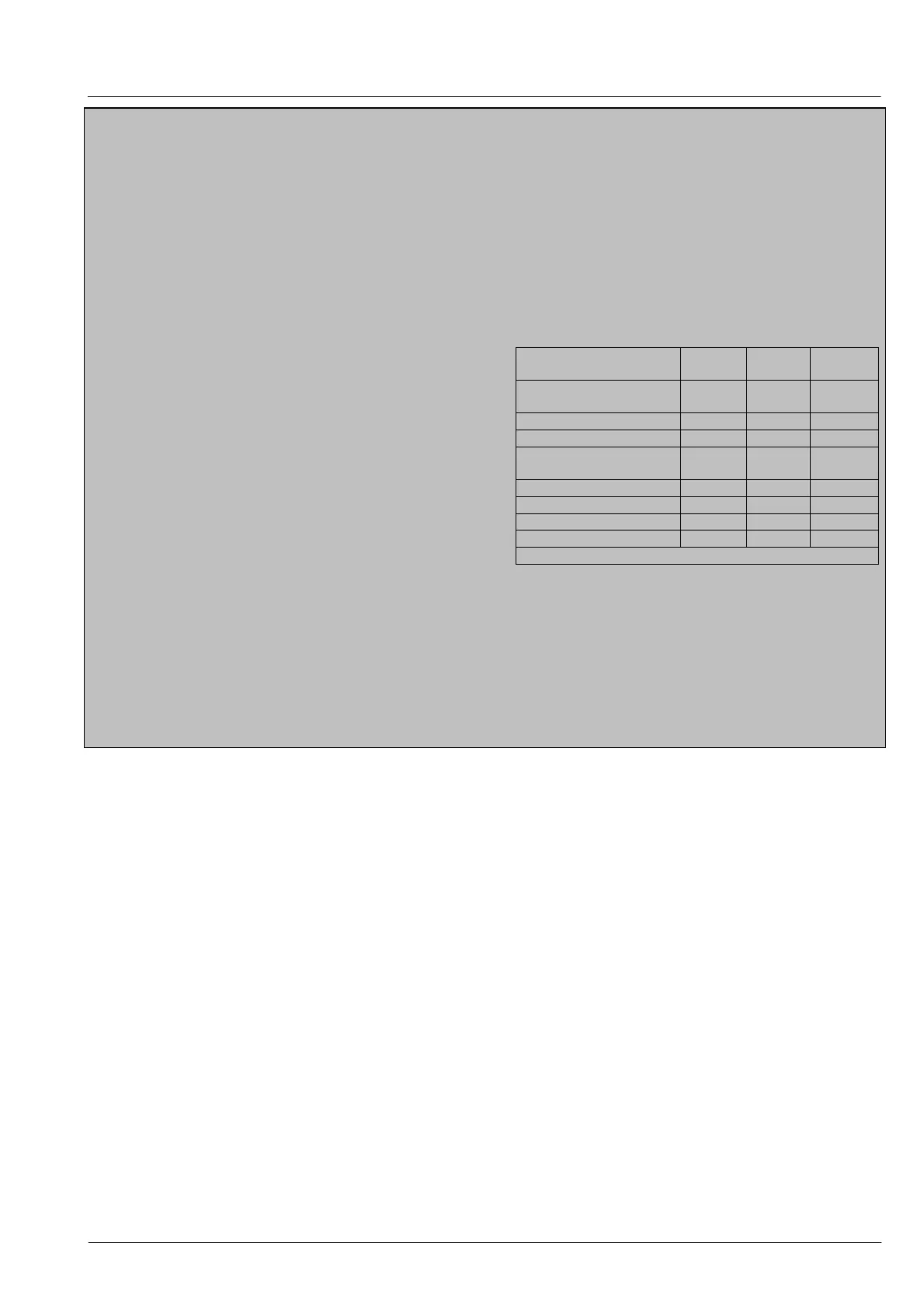

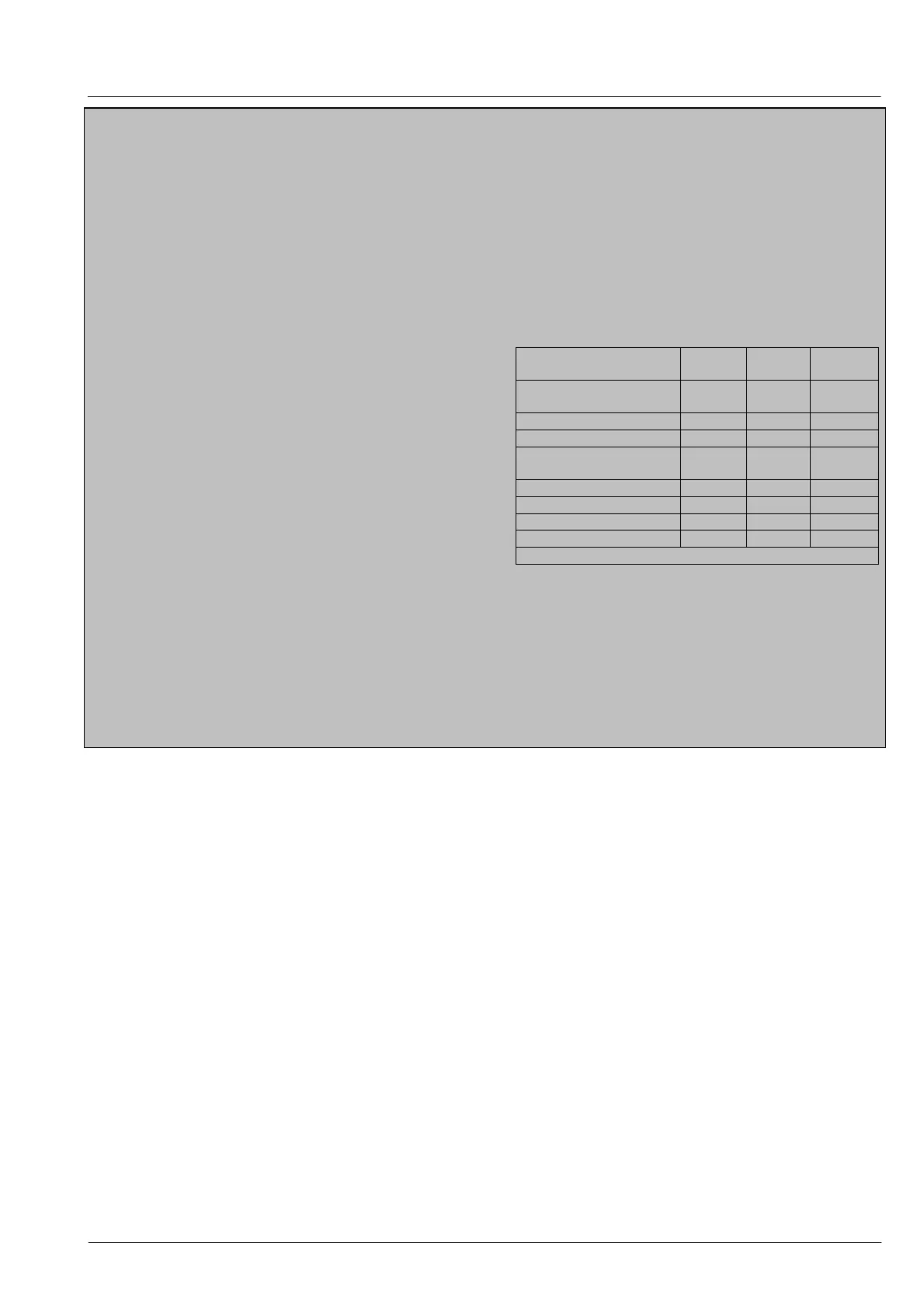

Description of the part

Part

number

Clean Replace

Steam feed pipe 063'404 x x *

HW valve pipe 063'205 x x *

Pipe 063'405 x x *

Coffee hot water feed

pipe

063'304 x x *

Tea hot water feed pipe 063'204 x x *

Level probe 067'068 x

Flow meter 061'226 x x *

Safety valve pipe 065'154 x x *

*Replace if the part is too heavily calcified

The decalcification process can be carried out using standard

decalcifying agents available on the market. Always follow the

instructions on the decalcifying agent pack. Thoroughly rinse

the treated components after the decalcification process.

If you establish, that there are unusually heavy deposits of

calcium on the components, you should carry out a water

hardness test, and depending on the result, discuss with the

customer what measures should be taken to reduce calcium

damage in the future.

Loading...

Loading...