Chapter 3 Functional descriptions

56 SMSO-2-02.03- 15.07.03

3.2.17 Booster

The booster is a heat storage device that transfers its heat to

the brewing water for the first servings of the product before it

enters the brewing cylinder. This compensates for the loss in

temperature in the brewing water through the brewing valve.

With this system, the brewing or outlet temperature can be

maintained at the optimum set values. In particular, this en-

ables those products that use small amounts of water (ris-

tretto/espresso) always to be served at a constant quality, from

the first cup onwards.

The booster consists of an aluminum body with a bore hole for

the water flow and a built-in heating cartridge. The temperature

is controlled by turning the heating cartridge on and off. The

temperature sensor connected to the housing transmits the

control signals. A safety fuse is built into the heater power

circuit as a safety element against over-temperatures.

The entire booster body is surrounded by heat insulation. It is

completely wired as a unit into the machine and used as a

replacement part.

Drawing symbol

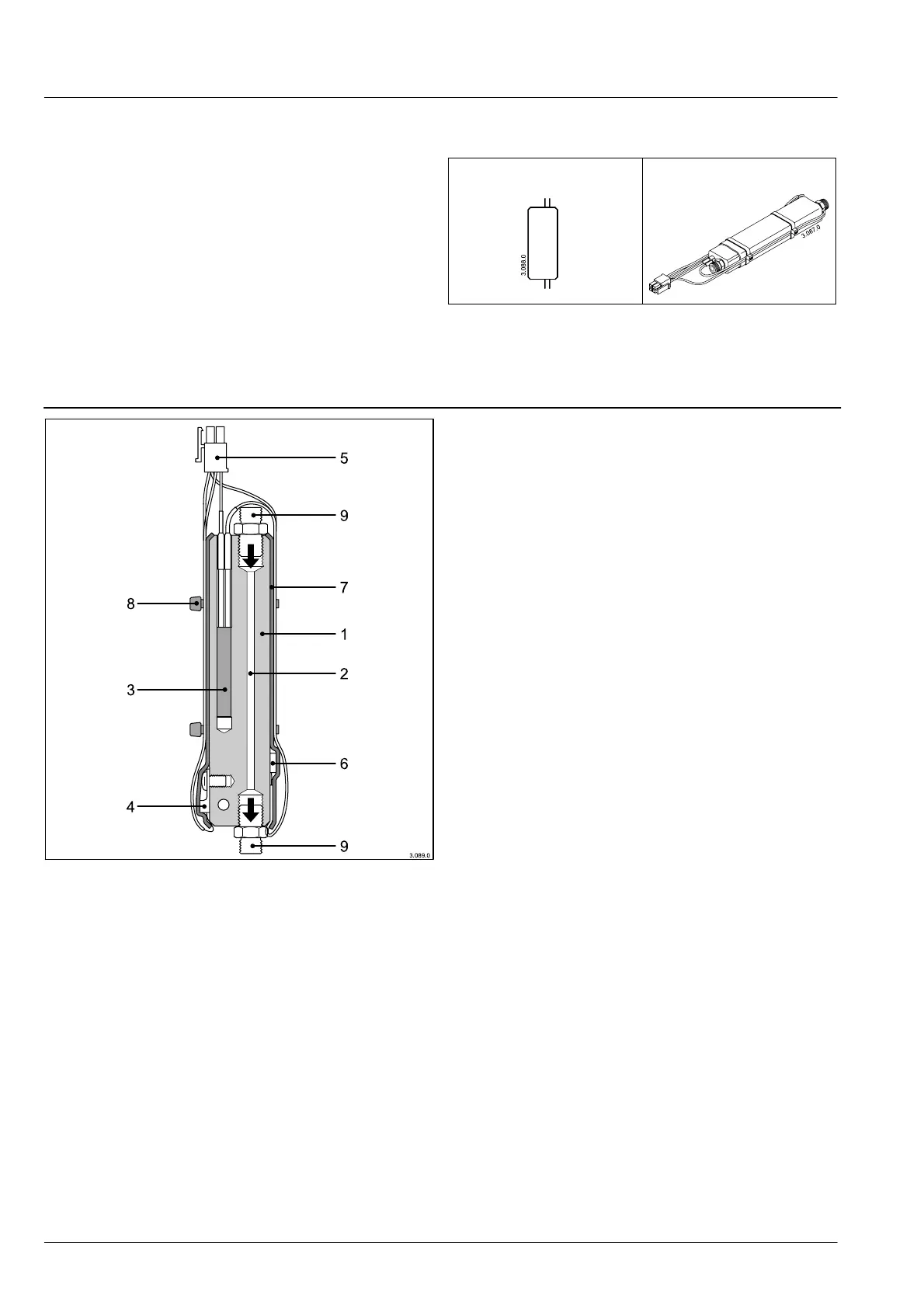

Illustration

Booster

1 Base body

2 Hole for water to flow through

3 Heating element

4 Temperature sensor

5 Plug casing

6 Over-temperature safety fuse

7 Insulation tube

8 Cable holder

9 PEEK connection nipple

Technical data

Nominal voltage: 36 V DC

Power rating: approx. 20 W

Resistance of

heating element at 20

o

C: approx. 35 -38 Ohm

Resistance of

Temperature sensor: 20 °C = 12.5 kOhm

26 °C = 9.6 kOhm

30 °C = 8.0 kOhm

Operating temperature: 110

o

C (hard coded)

Over-temperature safety fuse: 135 °C

Maintenance

Most frequent faults

clogged due to contamination / coffee residues

The unit does not evacuate correctly (pipe clogged /

closed)

The end of the discharge pipe is immersed into the water

level of the siphon.

Check

Check for contamination and coffee residues

Optimum heat transfer from the metal body (i.e. the heat stor-

age unit) to the brewing water can take place only if the hole is

clean and not clogged with residues or deposits. Slow heat

transfer has a negative effect on the quality of the product.

Service intervals

After every 45,000 coffee servings or after 12 months of op-

eration check the following:

Contamination

Loading...

Loading...