Chapter 3 Functional descriptions

SMSO-2-02.03- 15.07.03 55

Flush system

The flush system is used to compensate for the heat loss

from the coffee. If no coffee is served for 60 seconds, the

water pipe system (pipes and valves) between the hot water

unit and the brewing unit connection are pre-heated with hot

water before the brewing process.

To prevent the hot water from reaching the brewing unit, an

injector nozzle is installed inside the T-piece. The flush valve

downstream is open when at zero current, and the rinsing

water runs into the drip tray. After the flushing operation,

which lasts three seconds, the flush valve closes and the

water now runs into the brewing unit. After the brewing proc-

ess the flush valve opens again, so that the excess water can

flow again when the coffee grounds are repressed.

Additional water (bypass)

This system is used to produce a light-coloured coffee as pre-

pared for, among other things, coffee that is to have an injec-

tion of a spirit added to it. A proportion of the programmed total

quantity of brewing water is bypassed to the brewing unit in

order to dilute the strongly brewed coffee. This water is di-

verted from the instant heater outlet with a separate 2/2 way

valve, and is sent at the brewing unit outlet into the outlet pipe.

The bypass valve is closed at zero current.

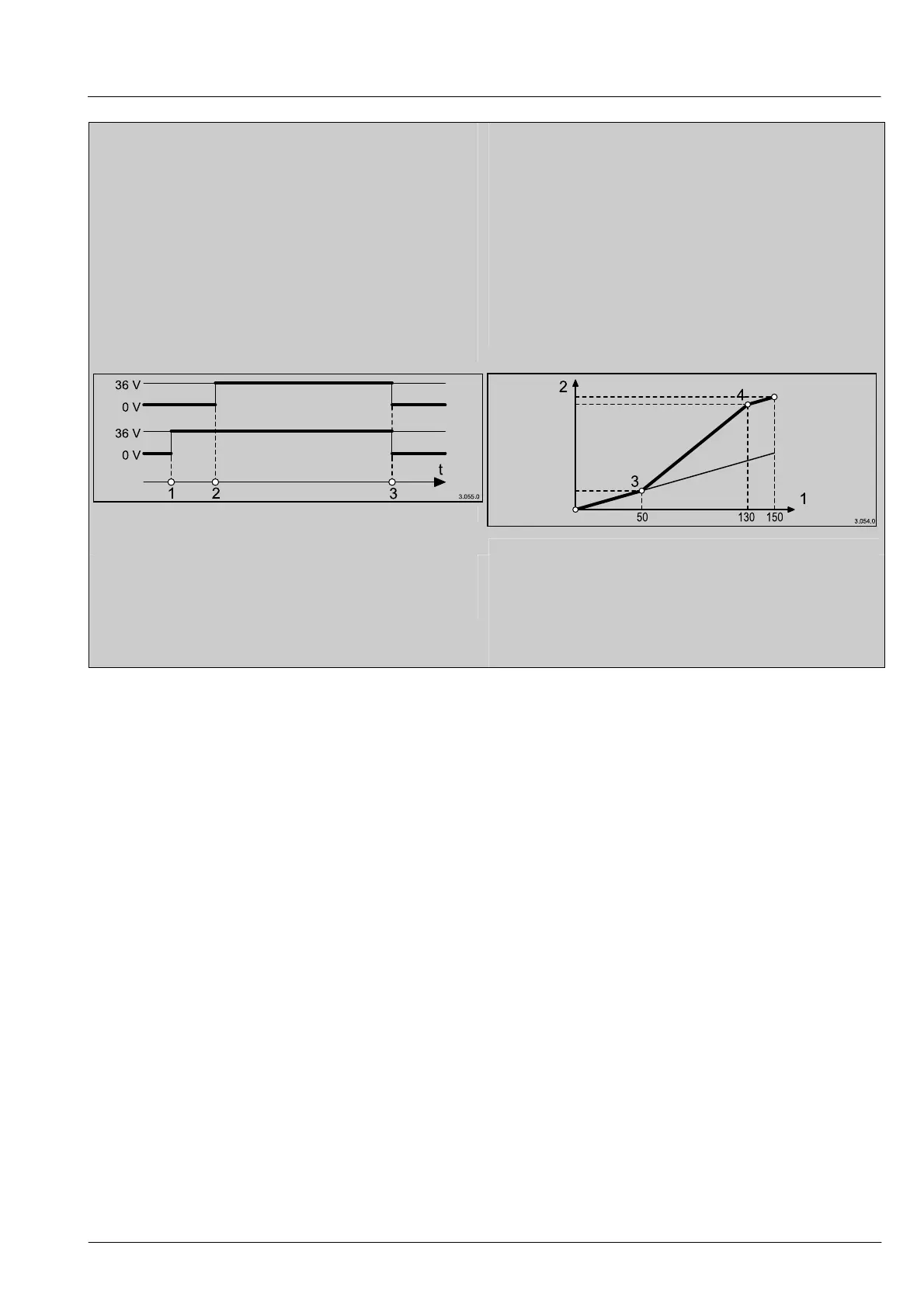

1 Open brewing valve

2 Flush valve closes after 3 seconds, then water

flows through the brewing unit

3 The brewing valve closes, the flush valve opens

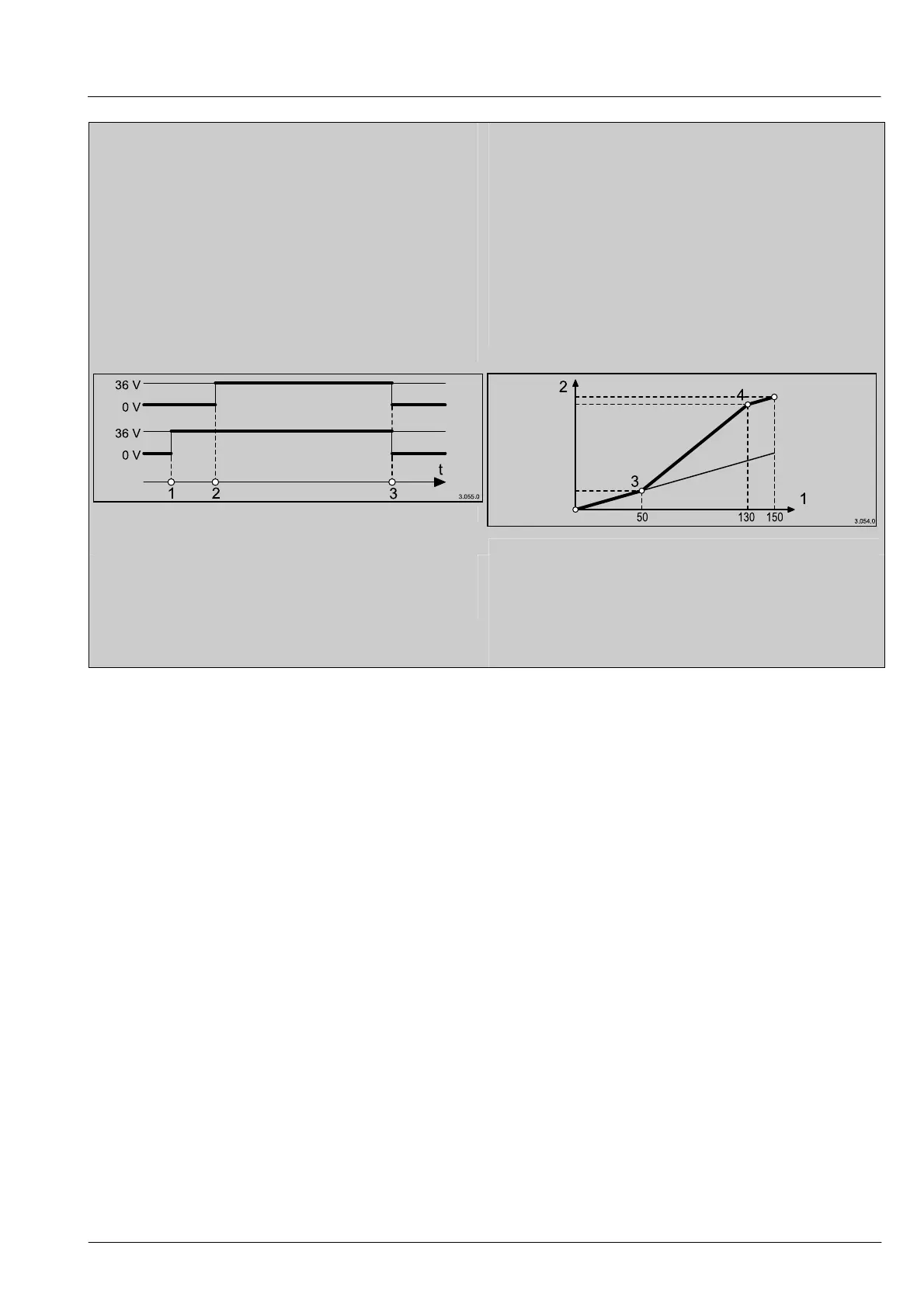

1 Number of pulses from the flowmeter (=”time”) quantity

dosing.

2 Quantity output

3 Bypass opens, dosing takes place according to number of

pulses.

4 Bypass is closed, the rest of the programmed quantity

runs through the brewing unit.

Loading...

Loading...