Chapter 3 Functional descriptions

54 SMSO-2-02.03- 15.07.03

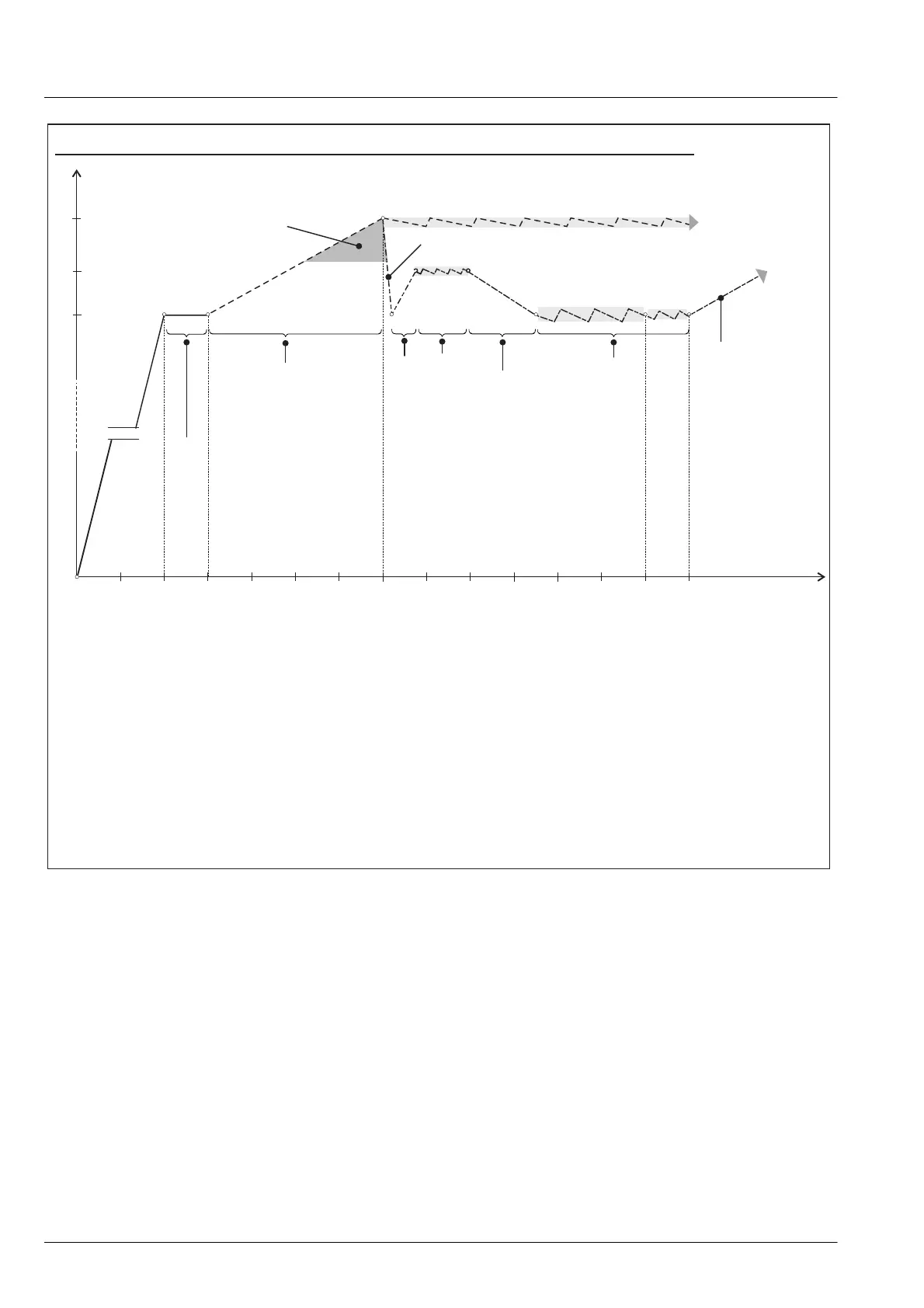

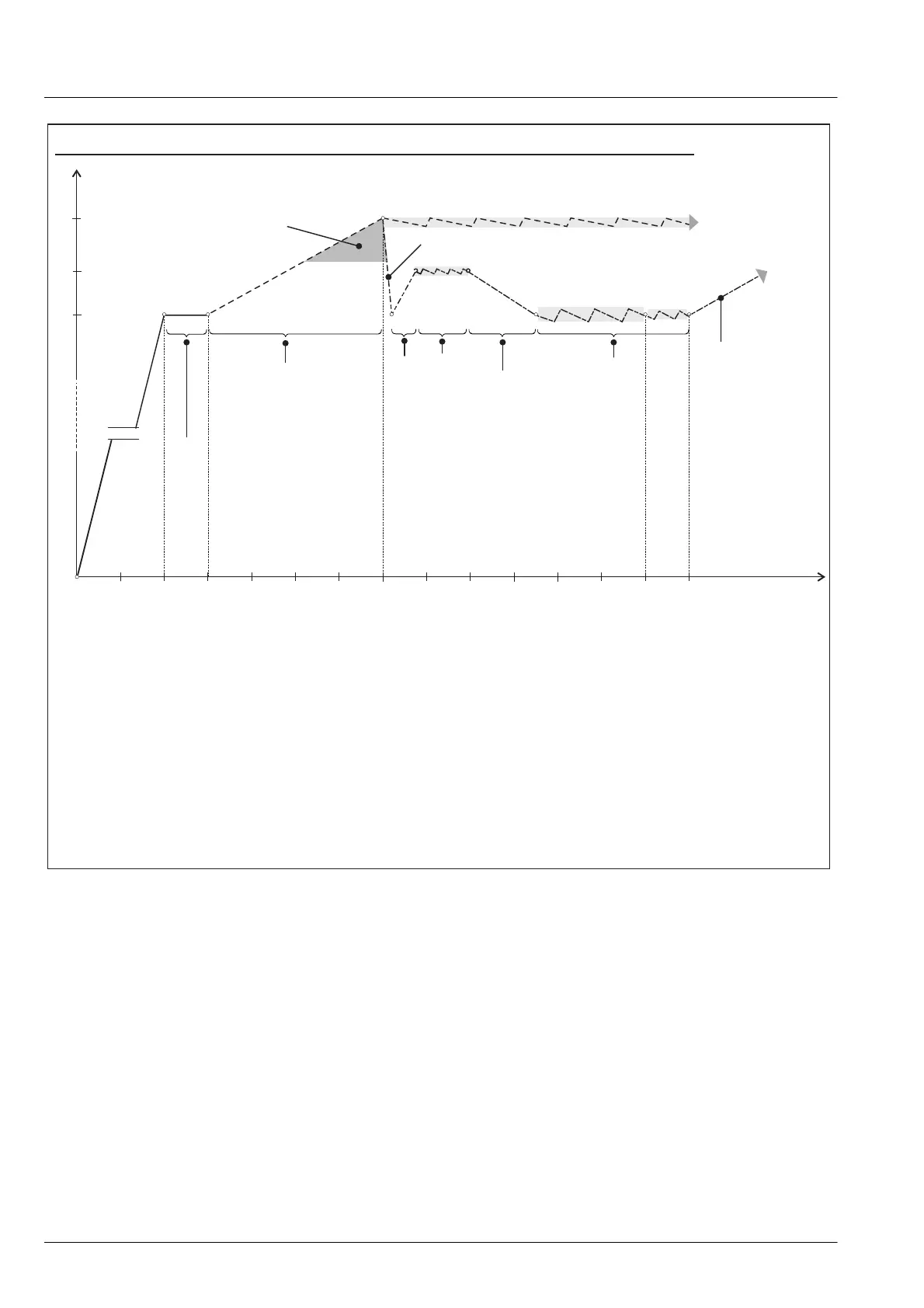

Temperature control for brewing system (flushsystem)

Explanations about the temperature diagram:

1.) The expressions over-temperature “1” and “2” are not meant in the sense of over-temperature as a

faulty operating status but as two loops of the temperature control.

2.) After 300 pulses from the flowmeter caused by uninterrupted product serving, it can be assumed that

the system has reached operating temperature. Therefore, the next product servings can be made at

basic temperature.

The absolute values of basic temperature, over-temperature 1 and over-temperature 2 do not stay

absolutely consistent in practise.

The actual temperature lies within a narrow temperature band about the theoretical value. The constant

cooling down of the machine, the product servings and the heating intervals cause the tolerances in

the temperature pattern.

102

93

86

0 2 4 6 8 1012141618202224

mint []

3.092.0

q

[ºC]

Temperature reserve to

heat up the system for

the 1. product serving.

Drop of temperature because

of product serving

Continuous heating during product

serving. 300 pulses from the flow-

meter or during 40 sec.

More product servings (temperature

drops to 86°C continue to heat

with basic temperature)

More product servings; the heating

temperature moves around 86°C.

No product serving

Heating up

No product serving

during 2 min.

Heat up until over-temperature 1 is

reached (2ºC/min during 8 min.

This happens only, if there has been

no product serving for at least 2 min.)

Heat up until over-temperature 1 is

reached (2ºC/min. during 8 min.)

Heat up until over-temperature 2 is

reached (7ºC immediately, during

product serving)

No product serving during at least

2 min.

2)

(= basic tem-

perature)

Loading...

Loading...