Chapter 3 Functional descriptions

SMSO-2-02.03- 15.07.03 61

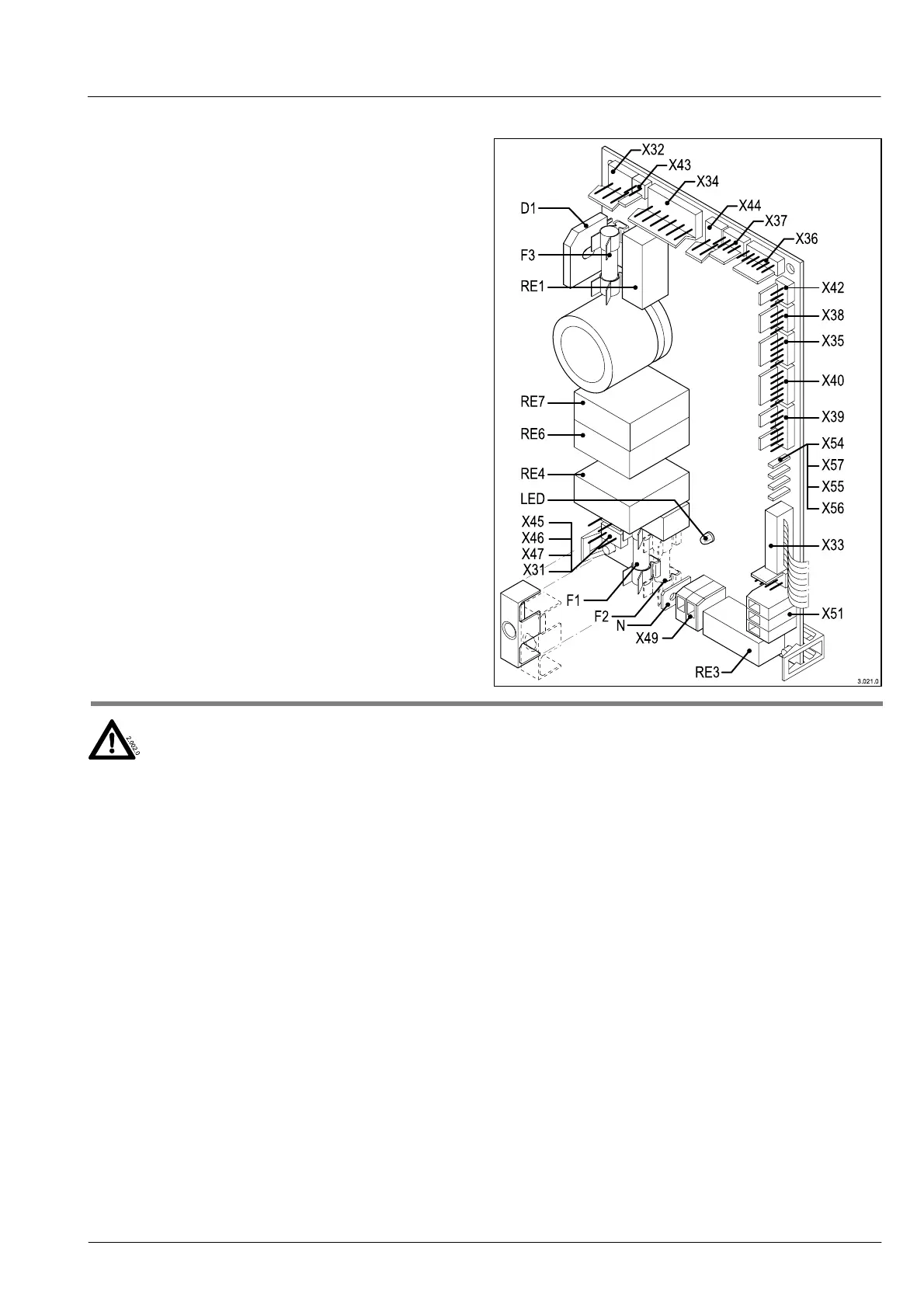

3.2.20 Power PCB

The Power PCB is the power distributor for the machine and

thus the interface between the unit control system and the

consumers. It contains almost all the elements required to

switch the consumers (motors, heaters, valves etc) either

direct or via additional power relays. The power PCB also

contains the power supply, the 36V DC supply with the fuses,

the separately mounted toroidal core transformer and the

rectifier.

The high current for the heaters in the instant heater and the

steam generator is provided via the separate relays.

Function

As soon as the machine is connected to the mains network

(main switch on), 36V DC voltage is generated in the power

supply of this PCB; the LED is lit. This voltage supplies most

of the motors, the cup plate heating and the solenoid valves.

The heavy users of power such as the heaters and the pump

are operated by the power relays at 230 V AC.

The unit control system has its own stabilised 5 V DC voltage

supply located on the unit control system PCB.

The motors and solenoid valves are switched on and off by

electronic switches (=power transistors, semi-conductor

switches) In transistorised circuits the current can be con-

ducted in different ways, the circuit type selected here is the

emitter circuit (see panel).

The rectifier and the power transistors get fairly hot especially

if they are in continuous operation. This heat loss must be

able to dissipate without hindrance. For this reason machines

should be erected so that sufficient cool air can circulate

through the ventilation slits. The power PCB, the toroidal core

transformer and the unit control system are not cooled directly

by the ventilator installed in the rear wall of the machine!.

DANGER TO LIFE / MATERIAL DAMAGE

When carrying out any work on electrical

appliances, fatal injuries may be caused by

electric shock, if live parts are touched.

Even at low voltages, contact with live parts

can also cause bodily harm to people, Such

work must be carried out only by authorised

and qualified electricians.

Static discharge caused while working on the PCBs

can destroy them. When handling PCBs make sure

that they cannot suffer electro-static discharge and

always store susceptible components in anti-static

packaging.

Safety fuses protect connected appliances from cur-

rent surges when an overload occurs, or in the event

of a short circuit. If the fuse values are too high, a

fault could cause material damage or a fire. Safety

fuses should therefore only be replaced with fuses

having the same nominal values.

Technical data

Primary voltage: 110 V AC ± 10 %

230 V AC ± 10 %

Secondary voltage, transformer: 24 V AC

Secondary voltage: 36 V DC

Transformer power: 120 VA

Primary fuse: 110 V: 3.15 A T

230 V: 2.0 A T

Secondary fuse: 8.0 A T

Stabiliser

Primary voltage: 110 V AC ± 10%

230 V AC ± 20%

Secondary voltage, transformer: 42 V AC

Secondary voltage, stabilised: 30 V DC

Transformer power: 140 VA

Voltage stabilising circuit

If there are large voltage fluctuations in the mains network, the

consumer voltage must be stabilised to a constant value by

means of an additional circuit. To this an appropriate toroidal

core transformer, together with an electronic stabilising circuit,

is fitted instead of the standard toroidal core transformer, This

circuit supplies a constant voltage of 30 V DC to supply all the

DC consumers.

When taking voltage measurements in the power electronics,

you should also note whether a voltage stabilising circuit is

present or not; the voltage values differ.

Loading...

Loading...