Chapter 5 Dismantling components

168 SMSO-2-02.05- 15.07.03

Assembly

Before starting to reassemble, make sure you are happy

that

all the components are clean, purified and dry

all worn parts have been replaced

faulty components have been replaced with new

ones

all the specified bearing and guiding surfaces have

been greased with the correct lubricating grease

(see functional descriptions, brewing unit, lubrica-

tion chart).

that the individual sub-assemblies have been cor-

rectly pre-assembled

To reassemble the brewing unit the sequence of work

steps is as follows: 9...8...7...6...5...4...3, then: Insert the

protection for the friction plunger and set up the right-

hand side panel. Fasten the screws on the right hand

and left hand side panels to a torque of 1.2 Nm.

Fitting the funnel

Place the brewing unit upright

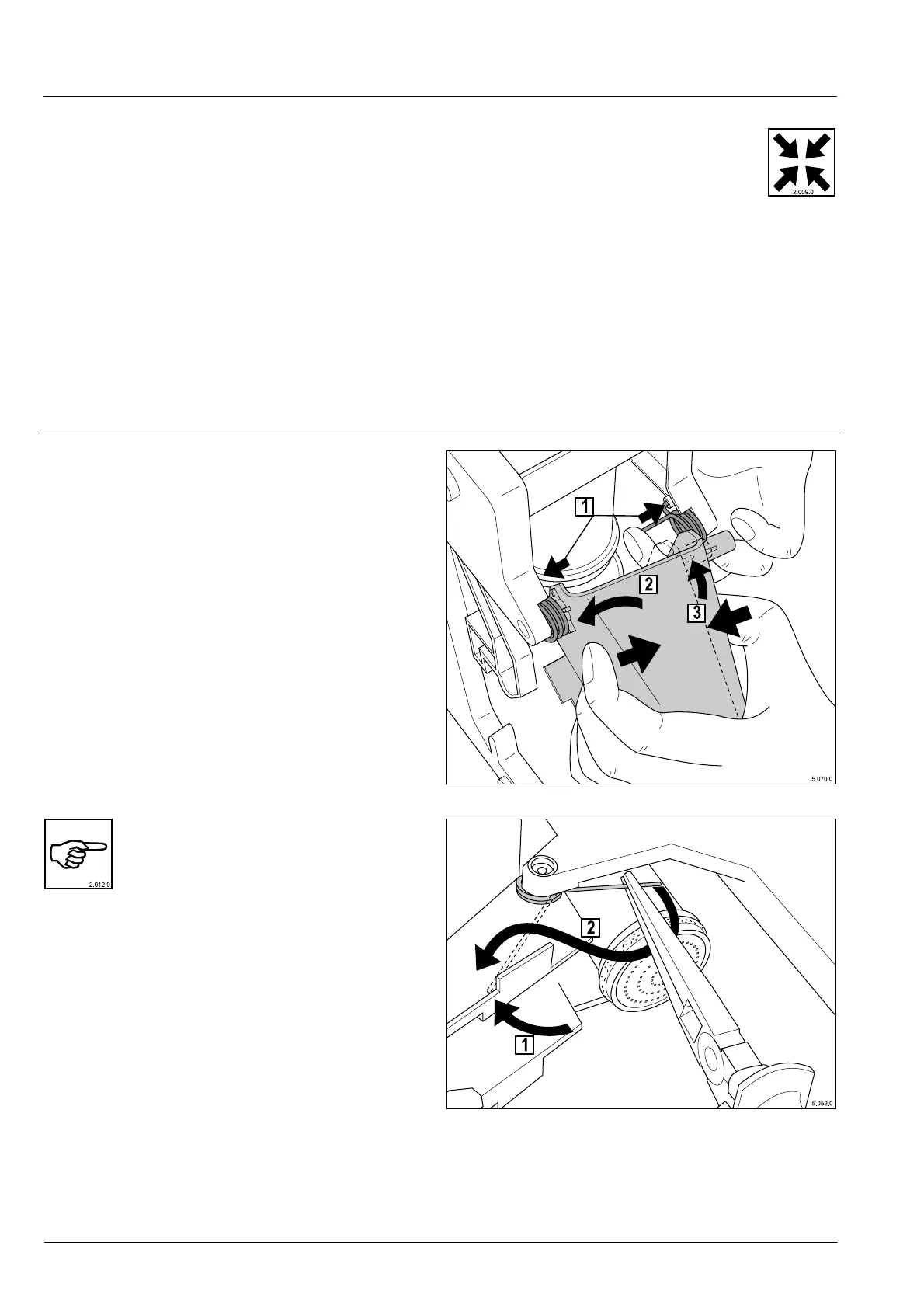

1. Insert the cranked leg of both springs into the side wall

bearings.

2. Push the funnel together with your hand and insert the

left-hand bearing necks through the leg spring into the

bearing on the side wall.

3. Adjust the right-hand spring to the bearing hole and

insert the right-hand bearing neck through the leg spring

in the bearing on the side wall.

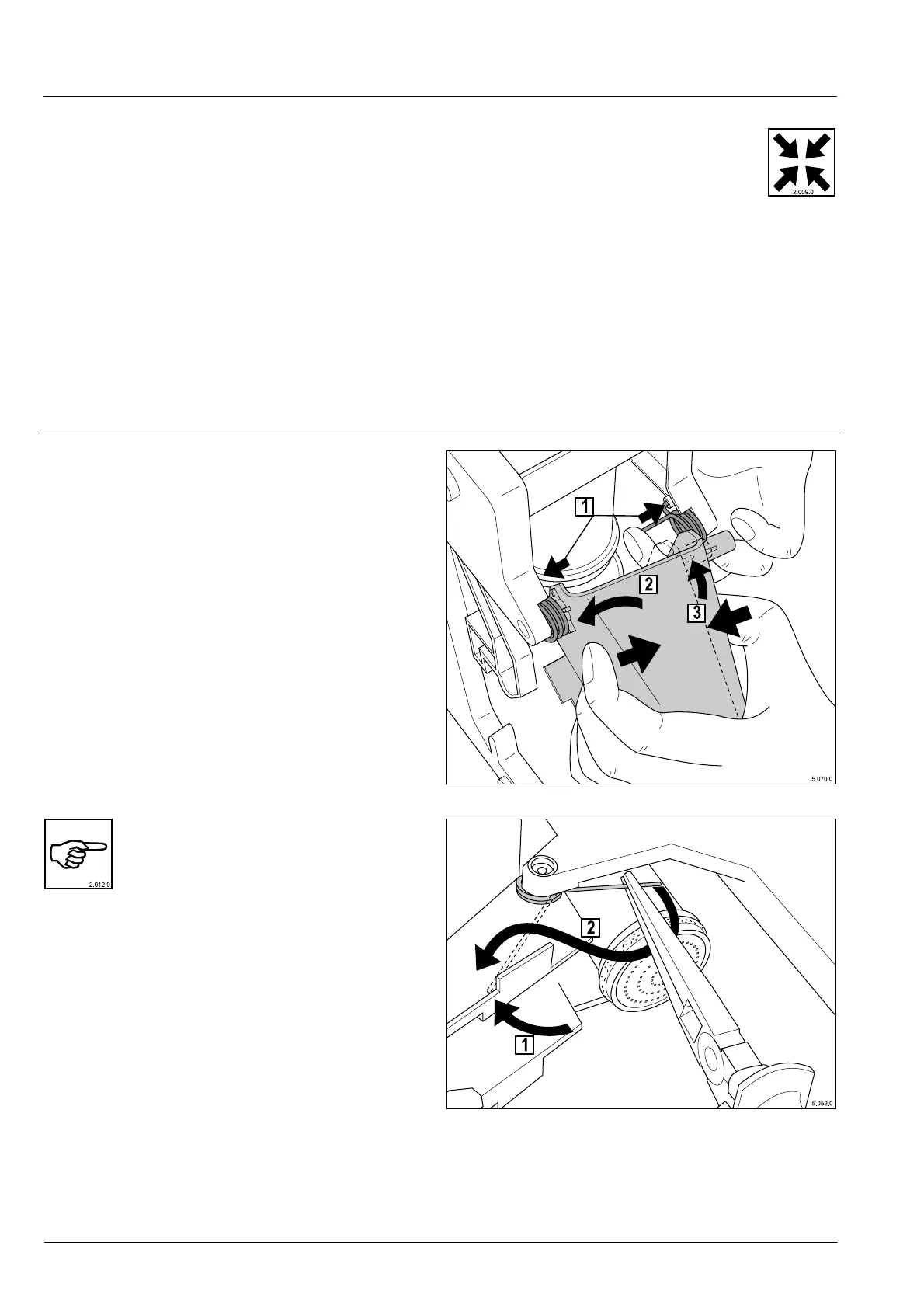

Tension both funnel springs: Swivel the funnel

outwards and with a pair of pliers place the leg

of the springs outwards behind the spring pad

stems. Carefully swivel the funnel back and

check the seating of the springs.

Loading...

Loading...