Chapter 2 General notes for service technicians

SMSO-2-02.02- 15.07.03 17

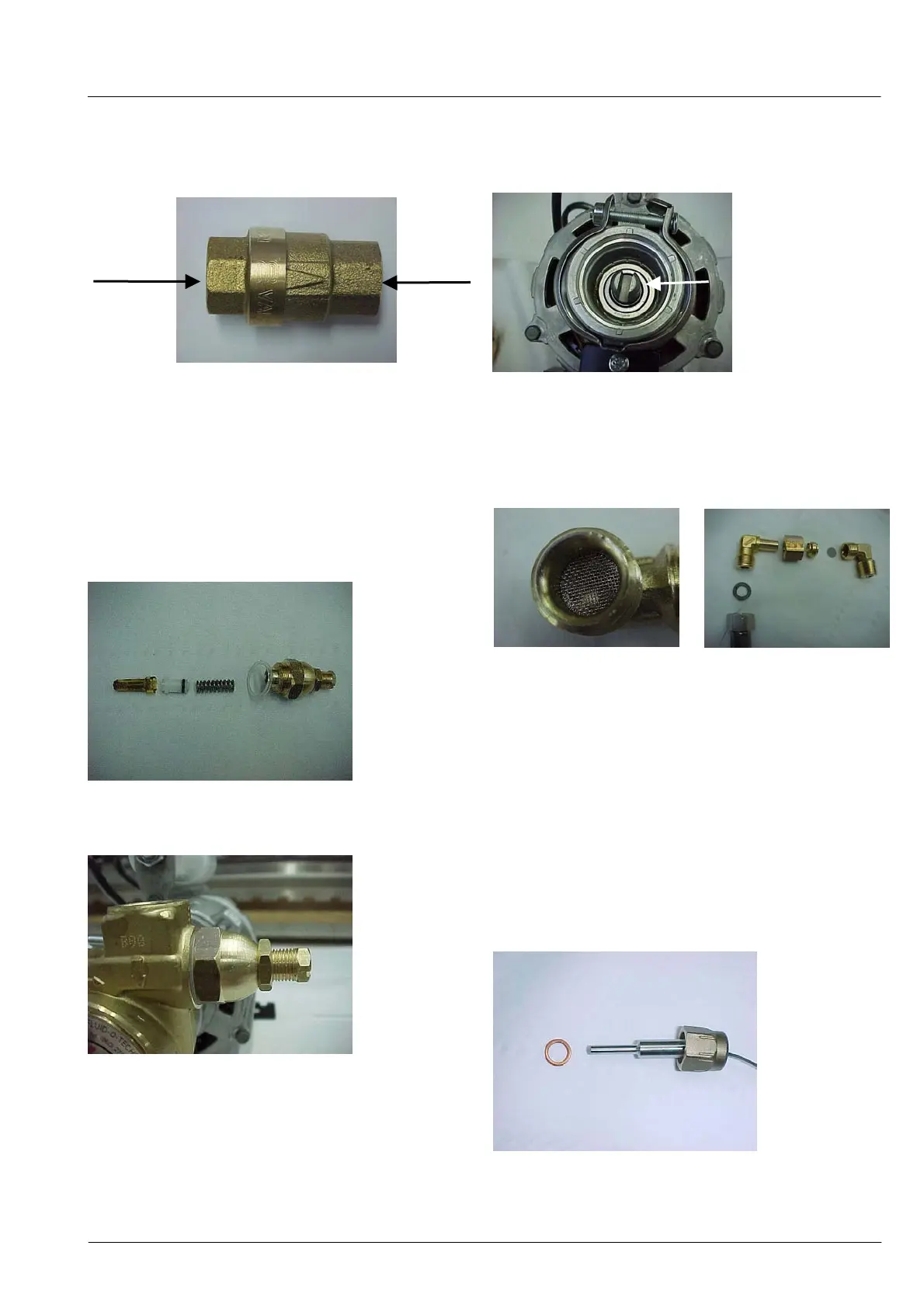

Note 12

Check the non-return valve for calcium deposits and

against the direction of the arrow for seal.

Note 13

Visual check for calcium deposits, damage,

contamination and seal of pipes.

Note 14

Check the pumps for seal, noise and blockages.

Dismantle the pump pressure setting device 065’706,

clean or replace, and liberally grease with grease suitable

for food applications 067’399, and refit.

Check the pump pressure setting of 7-7.5 bar against a

closed system.

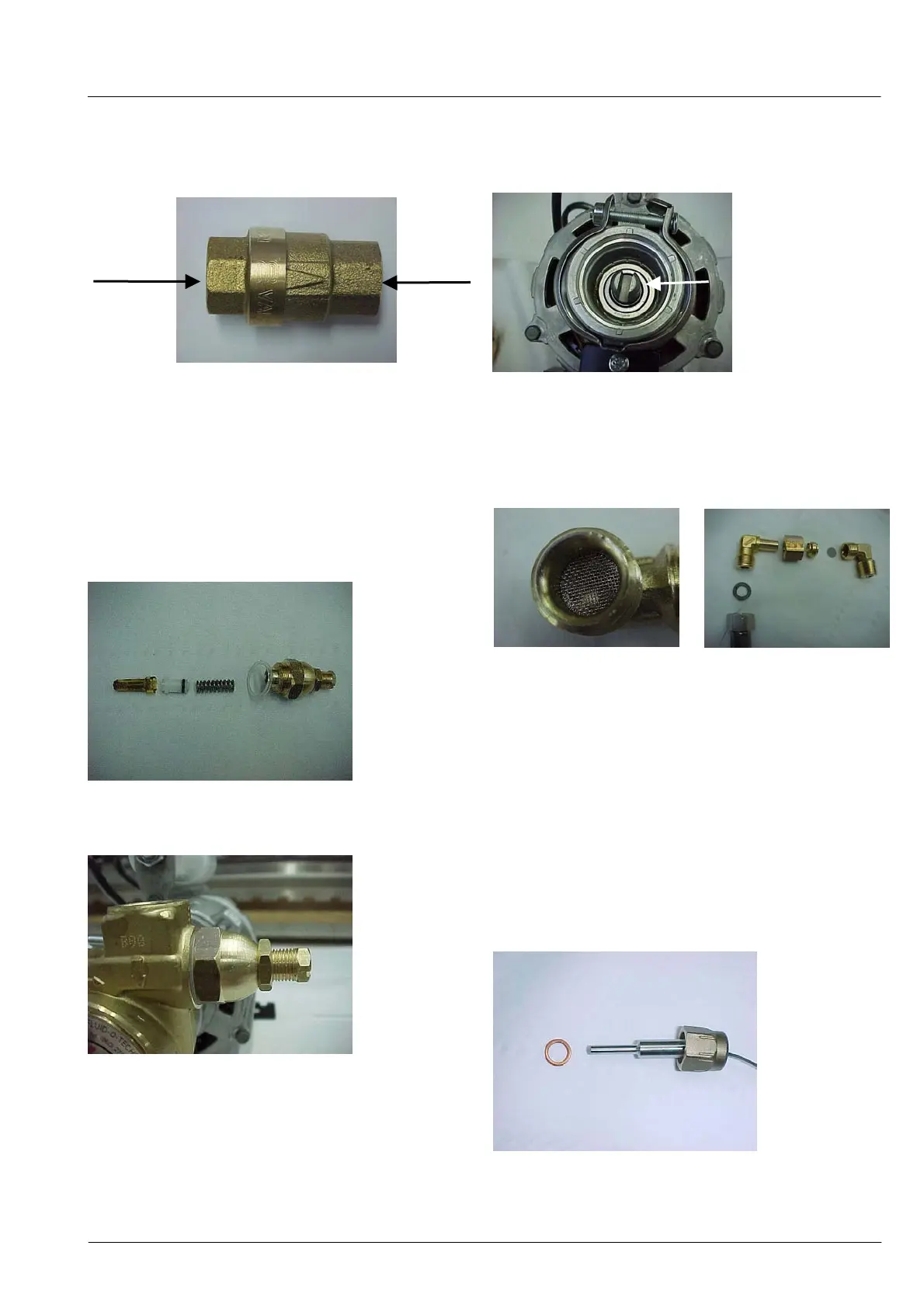

Note 15

Check the motor for proper function and storage. If the

storage is faulty, the motor makes a noise.

Note 16

Visual check for calcium deposits, damage,

contamination and seal of the filter in the pump inlet

screw fittings and at the water connection (mains

connection on the premises)

Note 17

Visual check for water tightness (seal at connections) and

damage to outer casing. The hose must be replaced in

the event of hose casing damage.

Note 18

Check that the water is able to run without hindrance, and

that the hose is water-tight.

Note 19

If the temperature sensor or the supply line can no longer

be tightened after checking an instant heater or a steam

generator, it is possible to use a copper seal 068'423.

No

passing

Passing

Loading...

Loading...