Chapter 3 Functional descriptions

46 SMSO-2-02.03- 15.07.03

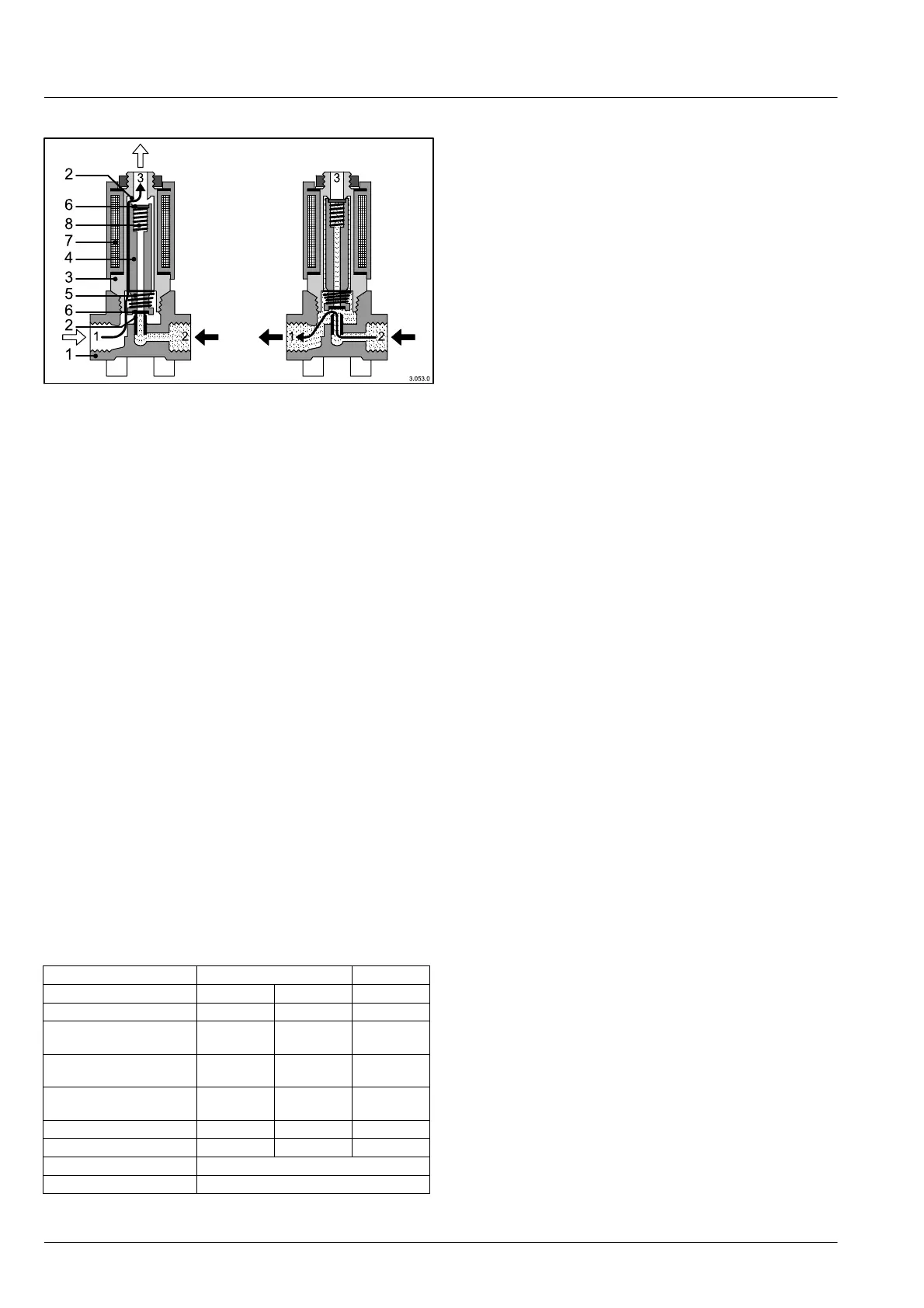

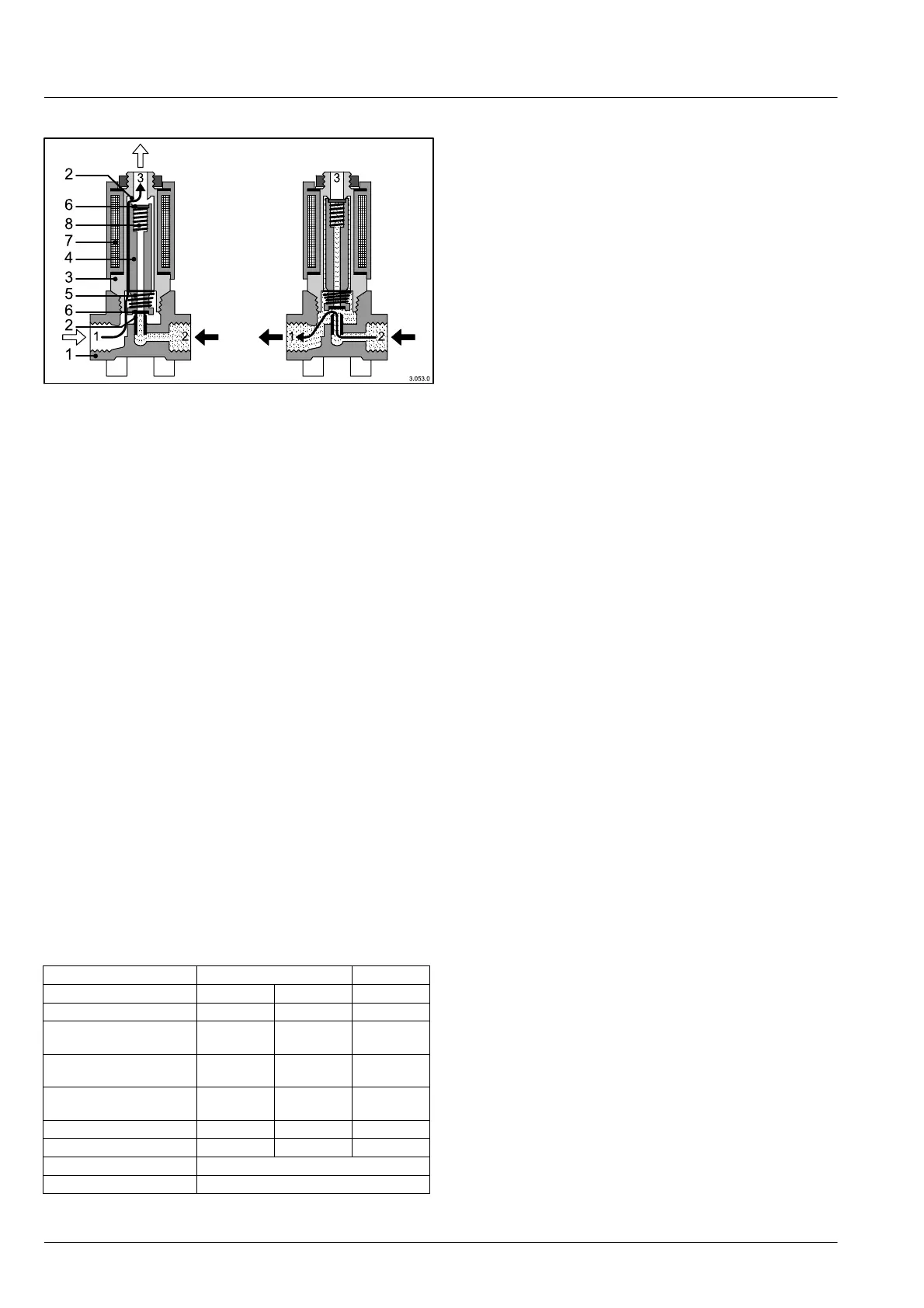

Solenoid valves (3/2 way)

When not powered up, connection 1 is connected to connec-

tion 3; connection 2 is closed.

1 Housing

2 Valve seat

3 Valve body (core guiding tube)

4 Closing element (plunger)

5 Closing spring

6 Core packing

7 Coil

8 Pressure spring for core packing

Valve battery

Several individual valves (2/2 or 3/2 way) with a common

pressure connection can be accommodated on a valve battery

in a single housing!

Applications

2/2 way valves

Brewing valve (with bypass)

Bypass valve (see panel in section on “instant heater”)

Flush valve (see panel in section on “Instant heater”)

Steam valves feed valve for steam element

3/2 way valves

Brewing valve (without bypass and flush)

Connection identification codes / control input

When connecting / replacing solenoid valves make sure that

they are installed in the correct direction. The identification

codes (1,2 etc.) are given in the spare parts catalogue, in the

module drawings.

Also please note that the switch positions which can vary

according to the intended use (open when no current, closed

when no current, etc.)

The 2/2 way valves that are tested for temperature and pres-

sure especially for use in coffee machines carry a label like

the one shown below on the magnetic coil: W<99ZZ

(9=number; Z=letter)

Technical data

Valve type [ways] 2/2 3/2

Application Brewing Flushing Brewing

Nominal width [mm] 1.6 3 (1/8") 1.6

Max. operating pressu-

re [bar]

12 11 16

Nominal voltage DC

[V]

24 24 24

Current consumption

[A]

0.33 0.45 0.33

Coil rating [W] 8.0 11.0 14.0

Coil resistance [Ohm] 60 48 41

On-time 100 %

Protection class IP 65

Maintenance

Most frequent faults

Calcified: Valve does not close, insufficient flow

Faulty coil: Valve does not open/close at nominal voltage

Check

The switching on and off of all solenoid valves can be tested

by means of an output test. (For details see “programming

manual”; system test, output test and select the valve con-

cerned).

Service intervals

After 45,000 coffees or after 12 months’ operation, check for

calcium deposits and wear on the seal in the closing element,

and check the valve seats.

Feed valve for steam element

Rinse water valve (refrigerator)

3/2-way directional control valve for water cylinder

(refrigerator)

Steam valve battery

After every 45,000 coffee servings or after 12 months of op-

eration replace:

brewing valves (2/2, 3/2 way)

Flush valve

Hot water valve (tea)

Steam valves (individual valves)

Use repair kits (part no. 063247) for the valve battery.

After 36 months of operation, replace:

Steam valve battery, complete

Rinse water valve (refrigerator)

3/2-way directional control valve for water cylinder

(refrigerator)

Feed valve for steam element

Loading...

Loading...