Chapter 3 Functional descriptions

SMSO-2-02.03- 15.07.03 71

Brewing system (coffee), continued ......... 01.04.2002

......... Serial no. 505123

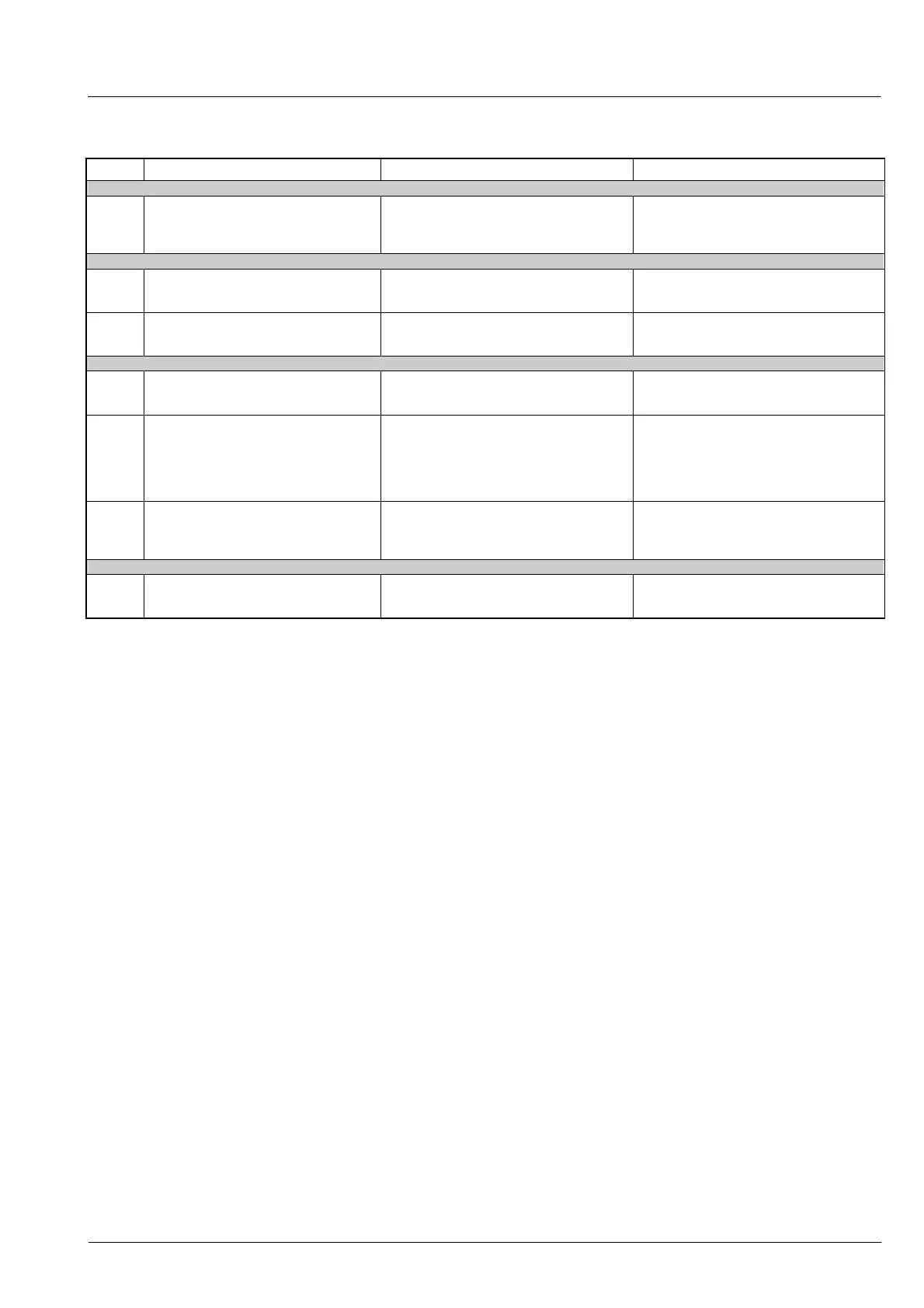

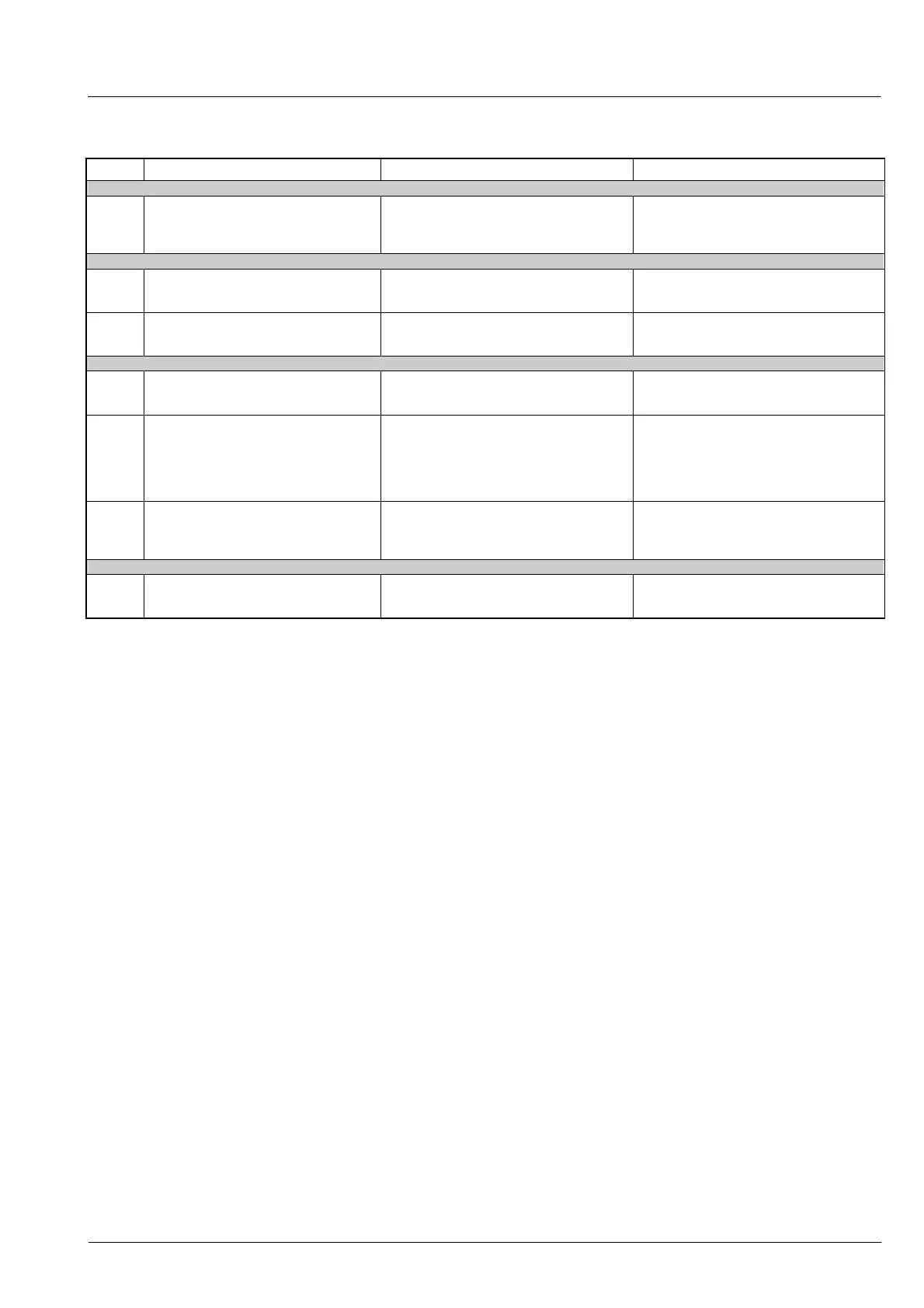

Process

step

Control system (electronic/electrical) Hydraulic system Mechanical processes

Heating the instant heater

10 The instant heater heating is switched on

and off according to the programmed

control conditions (transistor switches

power relay 11)

The water in the instant heater is heated.

Repress

11 Switch on piston motor to repress the

coffee grounds. The piston motor stays on

for approximately 0.2 seconds.

The brewing cylinder travels upwards a little

higher and presses the coffee grounds

The remaining water in the coffee grounds

flows through the brewing pipe and the open

flush valve into the drip tray.

Ejection of coffee grounds, brewing unit moves back to start position

12 End re-press process, reverse the direc-

tion of the piston motor to open the brew-

ing cylinder.

13 The brewing cylinder now moves down-

wards; the lower piston slides on the friction

piston 2000 and pushes the coffee grounds

out of the brewing cylinder. The stripper

ejects the coffee grounds into the drawer for

coffee grounds.

When the piston cannot go down any

further, its direction of rotation is reversed

via the piston motor current measurement

device.

The brewing cylinder moves back up, and

the friction piston 2000 retains the lower

piston until it is pulled out of the friction

piston 2000 through the brewing cylinder.

Start position of brewing unit

14 The microswitch on the machine sends a

“piston start position reached” signal; the

piston motor switches off

The brewing unit is in the start position.

Additional water

To made a weak coffee (for example so that a spirit can be added) there is a bypass system that is used for a programmed

period, while the product is discharged (step 8) to mix hot water from the instant heater through the bypass valve into the coffee

outlet pipe.

Loading...

Loading...