Safety and Functional Tester GLP2-i/e

During the test, test object and test leads must not be touched!

The safety measures required by law must be adhered to!

Schleich GmbH * D-58675 Hemer * 0049 / (0)2372 / 9498-0 * 0049 / (0)2372 / 9498-99 *

http://www.schleich.com * info@schleich.com 69

6.0 Test methods

6.1 PE resistance test

6.1.1 Explanations on the PE resistance test

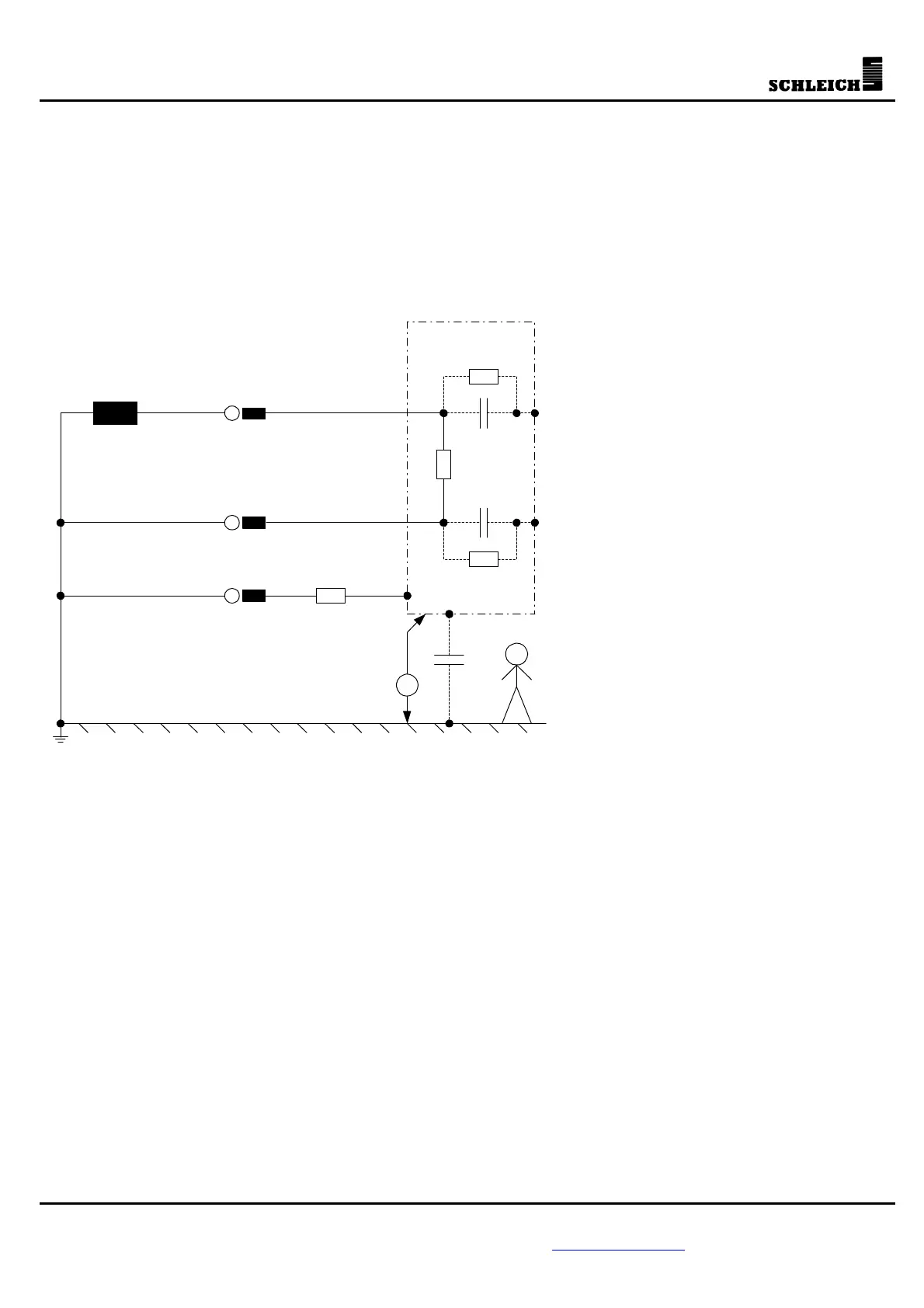

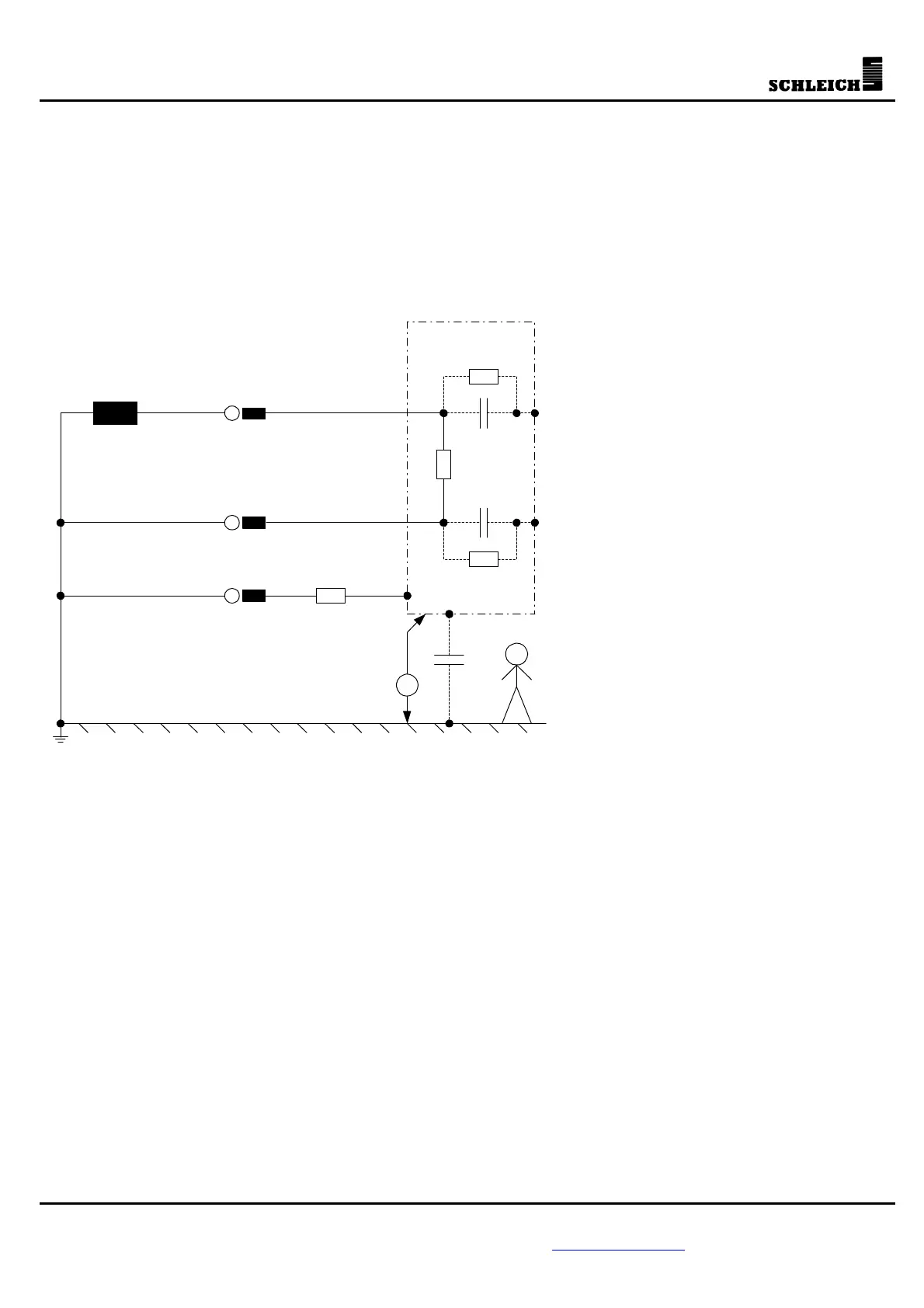

The PE resistance test is used for devices

of protection class I. It is checked,

whether the PE resistance is below a limit

value determined by standards. The

purpose of the test is to find out, whether

possible leakage currents generated in

the test object are correctly discharged to

ground. Faulty PE connections could lead

to a high touch voltage at metallic parts

of the enclosure. If these metallic parts

were touched, the so-called touch current

would be discharged to ground via the

respective person.

It is also possible that later, when

operating the device, the insulation inside

the device gets worse. This could lead to

a short-circuit between the current-

carrying leads and the enclosure of the

device. Through the short-circuit, the

device would be under voltage. In the

worst case, this type of fault could lead to

the enclosure being under mains voltage.

If now somebody touches the device, this

would bear a great risk. By generating a

short-circuit against ground, the PE is

supposed to protect the person. The

generated short-circuit current must

reliably be discharged by the PE against

ground.

For this purpose, a test current that is also determined by standards is lead through the PE. The level of the

test current is normally at least 1.5 times the nominal current of the device. The maximum current level,

however, is limited to 25A ... 30A. The test current produces a voltage drop at the PE, which is measured.

With the level of the test current and the voltage drop, the PE resistance is calculated afterwards.

Un

L

I

L

+ I

abl

I

abl

I

L

N

PE

I

abl

C

k

R

PE

V

Loading...

Loading...