Safety and Functional Tester GLP2-i/e

During the test, test object and test leads must not be touched!

The safety measures required by law must be adhered to!

Schleich GmbH * D-58675 Hemer * 0049 / (0)2372 / 9498-0 * 0049 / (0)2372 / 9498-99 *

http://www.schleich.com * info@schleich.com 80

6.1.3 Examples for application of PE resistance test

6.1.3.1 Manual test process of the PE resistance test

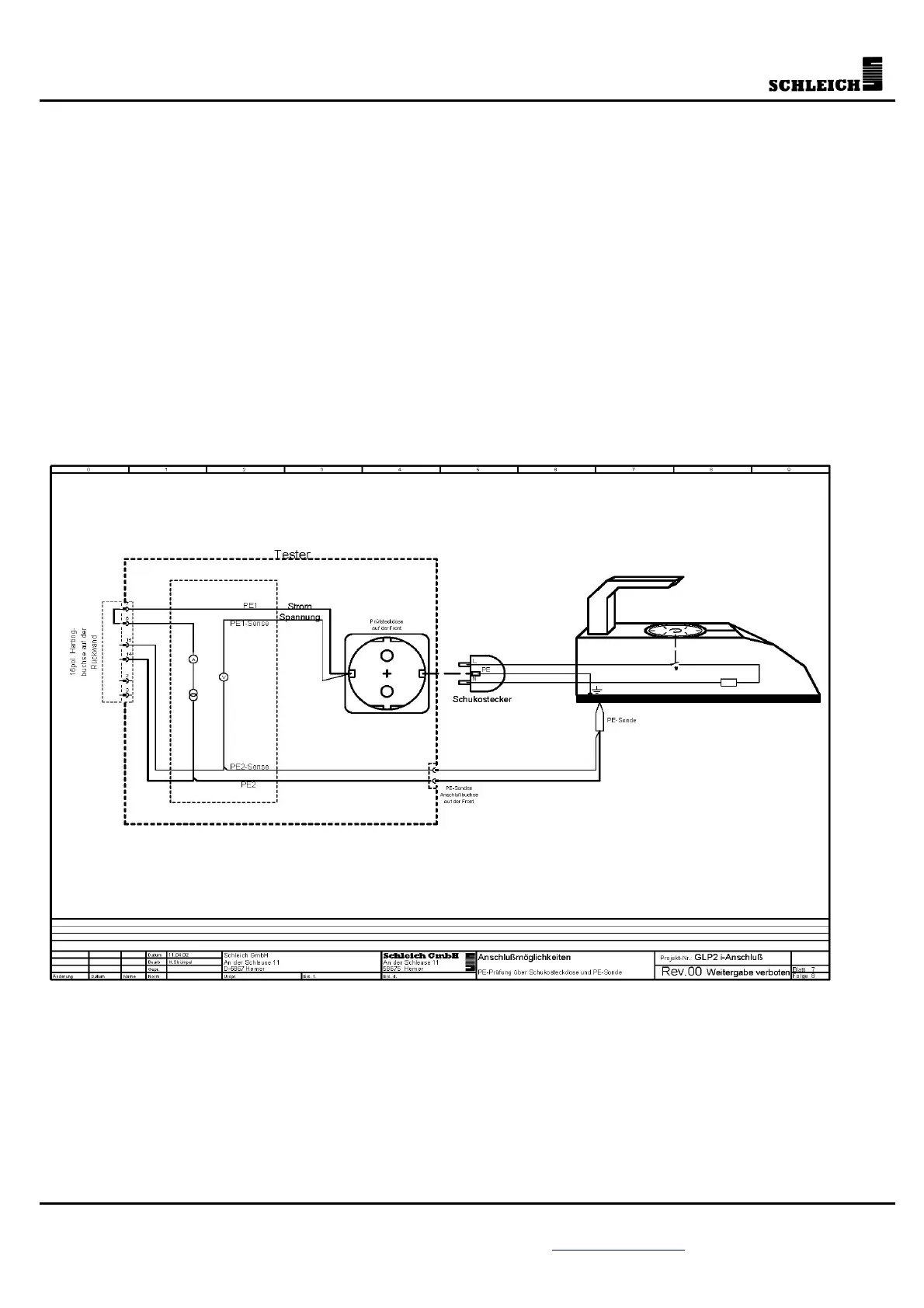

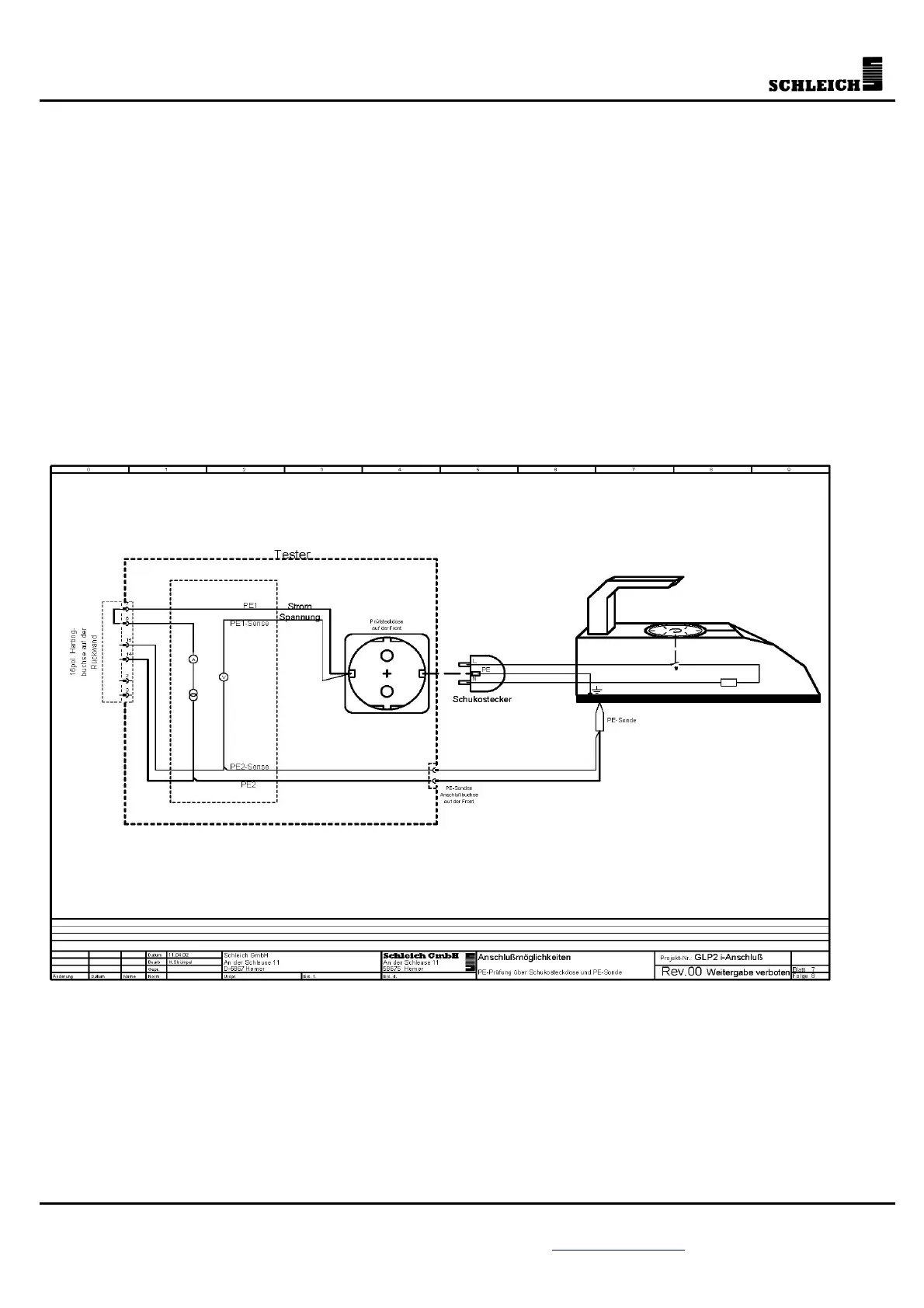

The manual PE resistance test is usually performed with the PE test probe. The test object is connected to

the testing device. It can be connected either via the socket at the front panel (the mains plug is inserted)

or via the industrial connection at the rear panel (via an adaptor or connection box). The test point to be

measured (e.g. enclosure contact) is now touched with the PE test probe. The test process is started by

pressing the switch inside the probe. When the PE resistance test is completed, the result is indicated on the

display and the test process is continued with the next test method of the program. If a limit value is

exceeded, the test can be repeated as often as it has been set in the data of the PE test or in the General

data. Reasons for exceeding a limit value can be, for example, a loos connection lead at the test object,

slipping with the probe, a coat of lacquer on the test object or a PE that is not connected to the test object.

In case of “no go” it is possible to interrupt the test process immediately – the other tests of this test

program will not be executed.

Example:

Loading...

Loading...