Operating Instructions GM35

Probe Model

Maintenance

8009389/07-2006 © SICK MAIHAK GmbH • Germany · All rights reserved 69

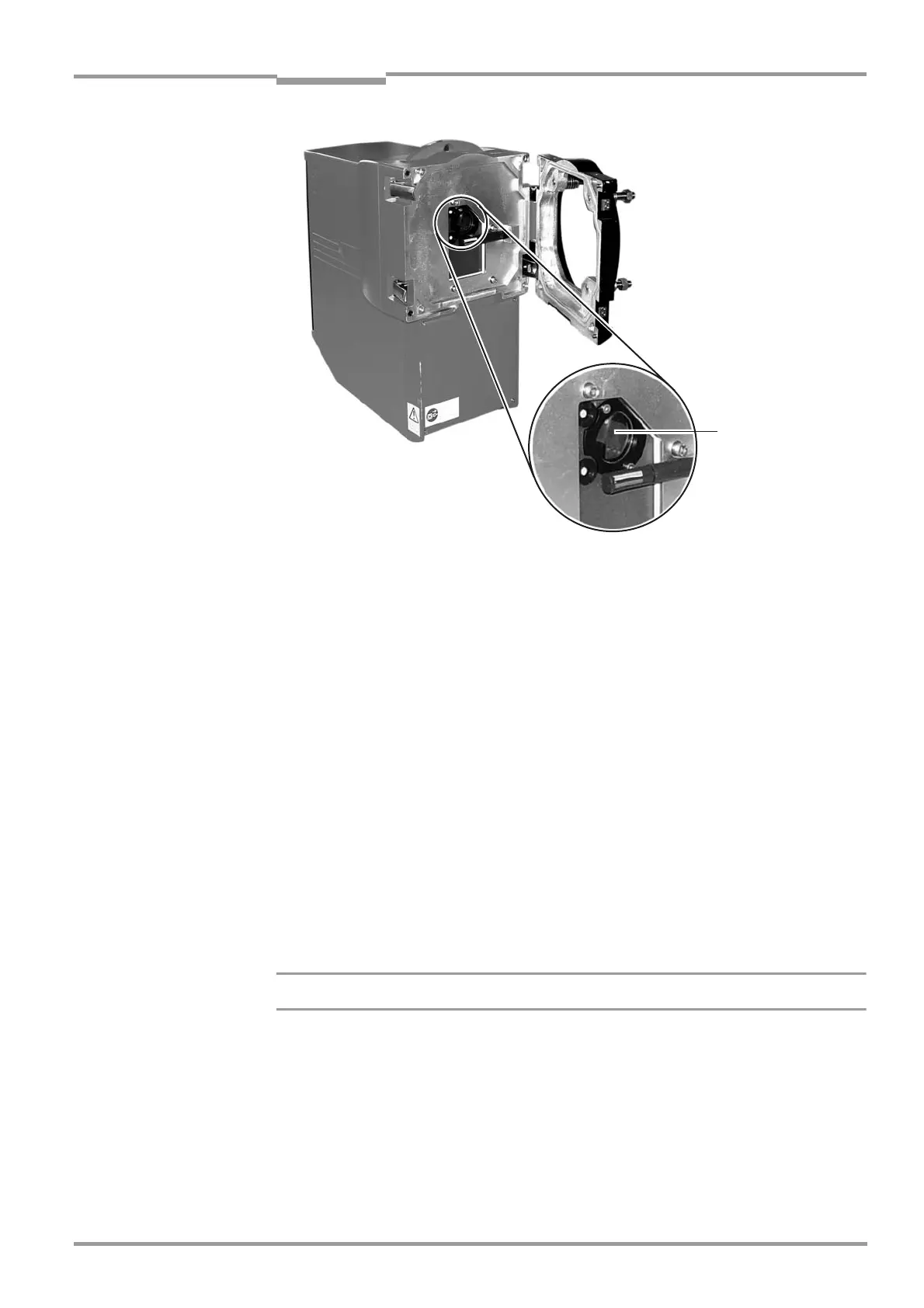

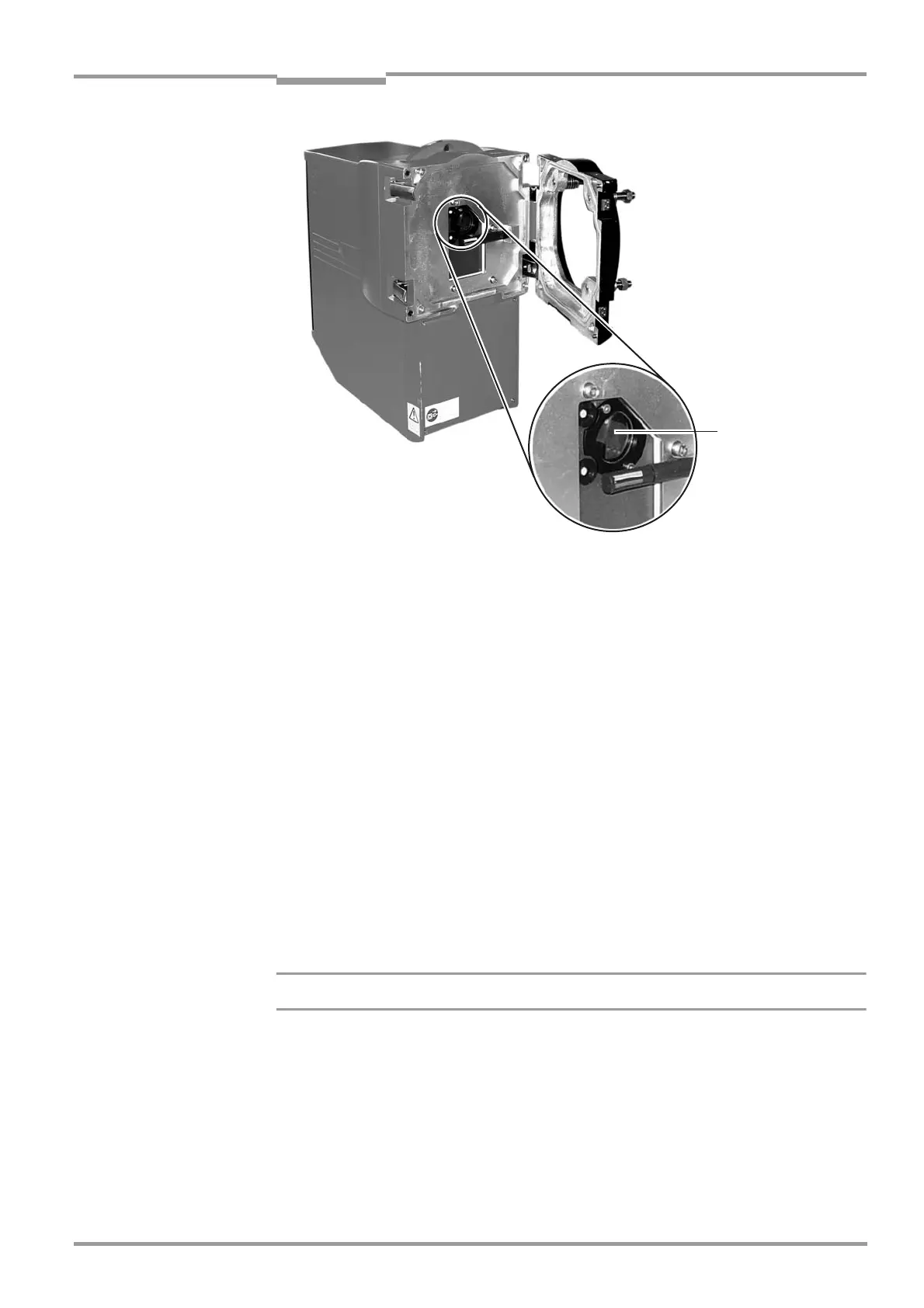

Fig. 37 Optical boundary surface

8.3 Maintenance activities on the purge-air unit

Only if purge air

is used

This Chapter only applies to GM35 configurations with purge-air supply, that is, those using

a GMP measuring probe. The reliability of the purge-air system is essential for ensuring the

availability of the measuring system. Maintenance of the purge-air supply is straightforward,

but should be carried out extremely carefully.

Prerequisites for maintaining the purge-air supply:

– The measuring probe with the SR unit is located outside the measurement gas duct; if

the duct contains a partial vacuum that is sufficient to flush it adequately with ambient air

when the purge-air supply is removed, the probe can remain inside the duct while the

purge-air unit is being maintained.

– The SR unit has been opened fully on the flange attachment so that any dust blown

through the purge-air hose during maintenance is not deposited on the optical boundary

surfaces of the SR unit and measuring probe. As described below, the purge-air hose

should be disconnected from the measuring probe while maintenance is being carried

out.

8.3.1 Preparation and general inspection

Never switch off the purge-air unit while the measuring probe is in the duct!

‡ With the purge-air unit switched on, remove the purge-air hose from the purge-air inlet on

the measuring probe or optional differential pressure monitor to prevent any dust that

has been released during maintenance from being deposited on the optical boundary

surfaces of the measuring probe and SR unit.

‡ Switch off the power supply (three phase) to the purge-air unit and, if necessary, attach

a visible warning to prevent it from being reconnected inadvertently while maintenance is

being carried out.

Optical boundary

surface (front window

Loading...

Loading...