Model Designations and Specifications UMSITRPDS3-1

November 2005

9-14

Flanged Level Transmitter Accessories

Order number

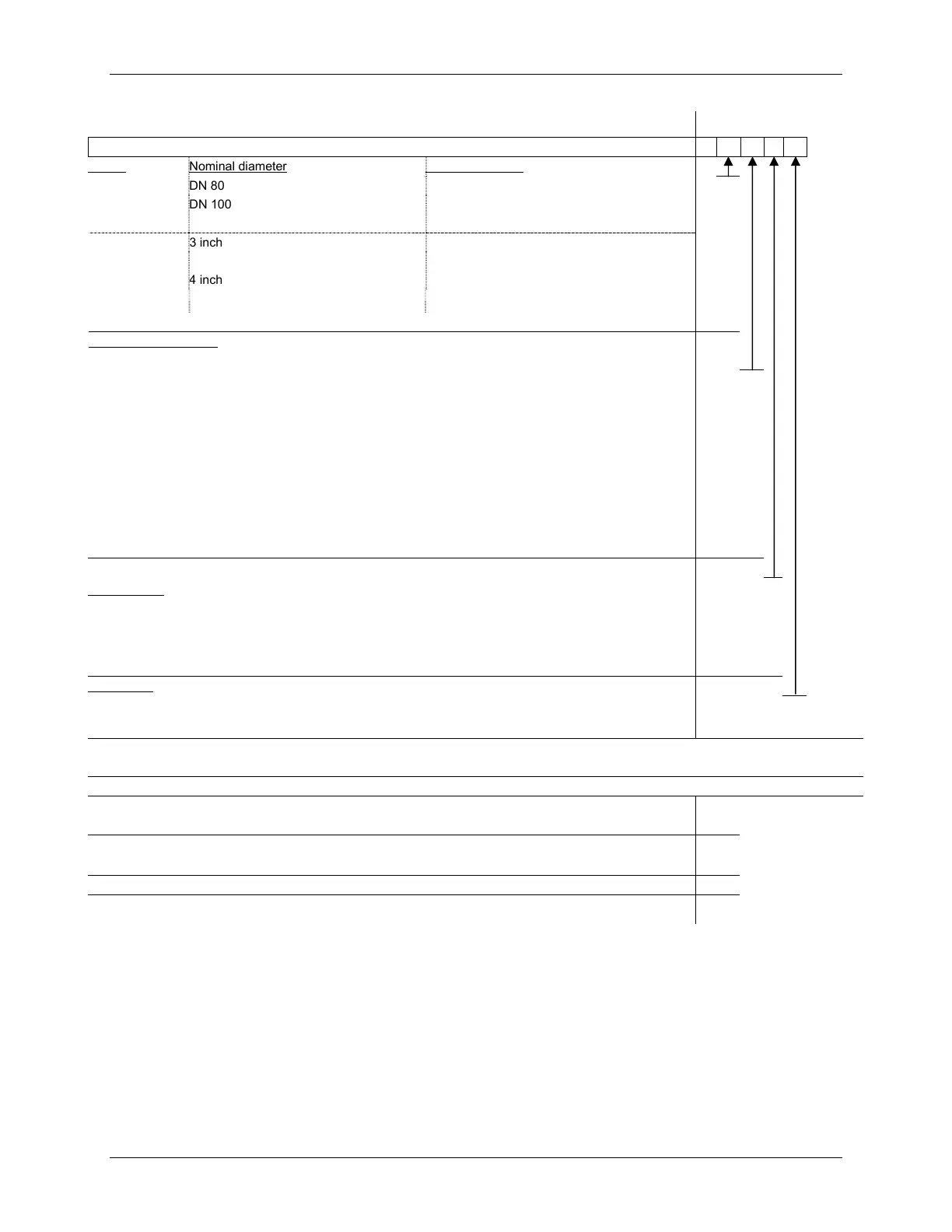

Mounting flange, mounted directly on transmitter, two-wire, 7MF4912-

3

Flange Nominal diameter Nominal pressure

Connection per DN 80 PN 40 psi

D

DIN 2501 DN 100 PN 16 psi

G

PN 40 psi

H

Connection per 3 inch 150 lb/sq. in.

Q

ANSI B 16.5 300 lb/sq. in.

R

4 inch 150 lb/sq. in.

T

300 lb/sq. in.

U

Special version according to customer specifications

Z J1Y

Material of wetted parts

Stainless steel M.-No. 1.4571:

Without foil, uncoated

A

With PTFE foil

1)

E

With ECTFE coating

1)

F

With PFA coating

1)

D

Monel 400, W.-No. 2.4360

G

Hastelloy B2, W.-No. 2.4617

H

Hastelloy C276, W.-No. 2.4819

J

Tantalum

K

Hastelloy C4, W.-No. 2.4610

U

Special version to customer specifications

Z K1Y

Smooth processing face according to DIN 2526, Form D:

Tube length

2)

Flush mount

0

2” / 50 mm

1

4” / 100 mm

2

6” / 150 mm

3

8” / 200 mm

4

Filling liquid

Silicone oil M5

1

Special version to customer specifications

9 M1Y

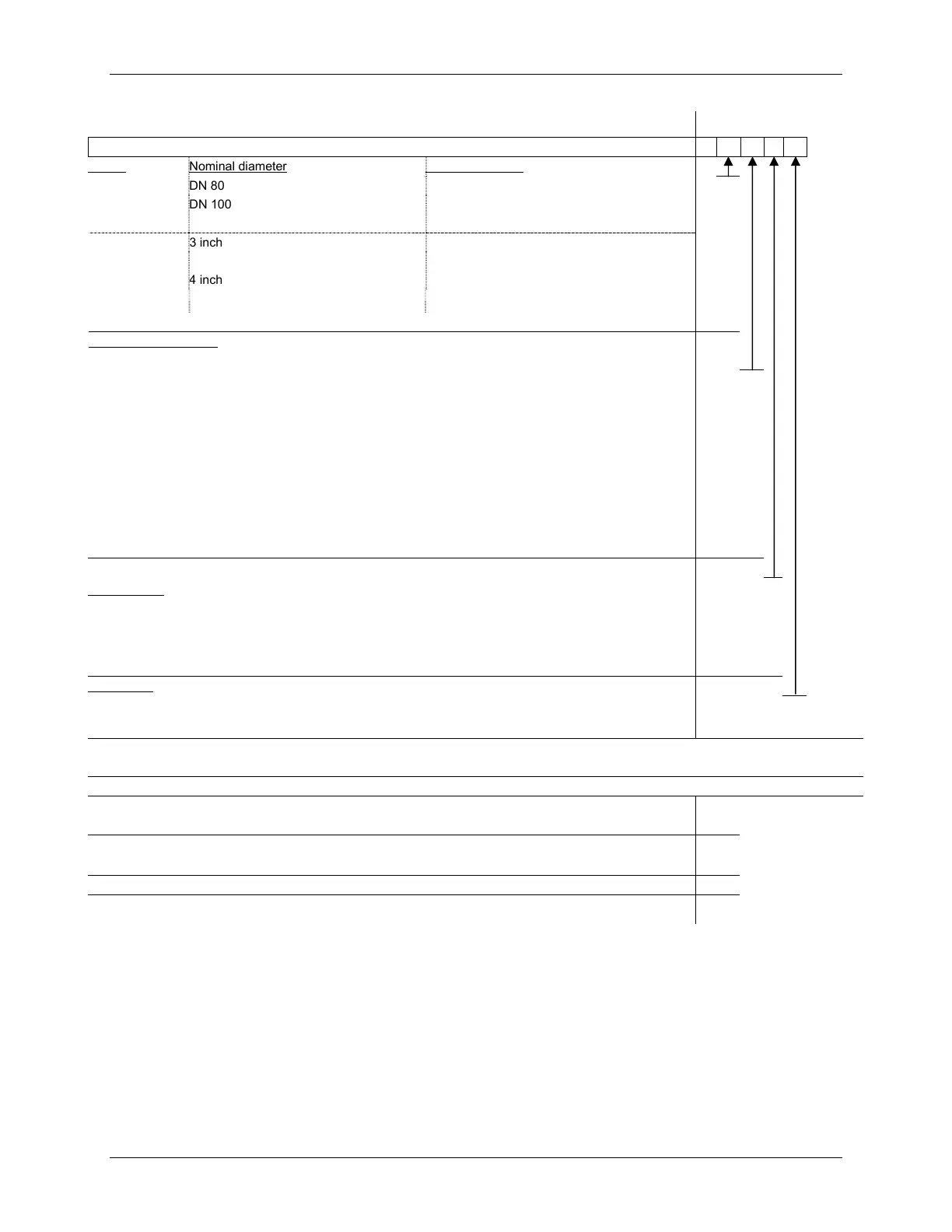

Other versions for mounting flange

Add "-Z" to the order number and add short spec.

7MF4912 - . . . . . -Z

With flame barrier for mounting in zone 0 (with documentation)

A01

Manufacturer test certificate M acc. to DIN 55 350, Part 18, and ISO 8402 (not with supplement "P01")

C11

Acceptance test certificate B according to DIN 50 049; see Section 3.1 and EN 10 204

C12

Vacuum-proof version (use in vacuum pressure range)

V04

Calculation of span of the corresponding transmitter, enclose completed questionnaire! (Not with supplement

“P01.”)

Y05

Notes:

1)

For vacuum on request

2)

Prices for the stated tube lengths are based on the material of the wetted part: stainless steel M. No. 1.4571.

Prices for other materials are available upon request.

Loading...

Loading...