Configuration

5.4 Mounting

1FW3 complete torque motors

Configuration Manual, 08/2020, A5E46027705B AA

113

Connecting the rotor to the drive shaft

You can connect the rotor of the 1FW3 motor to the customer drive shaft either using a

flange or a clamping element:

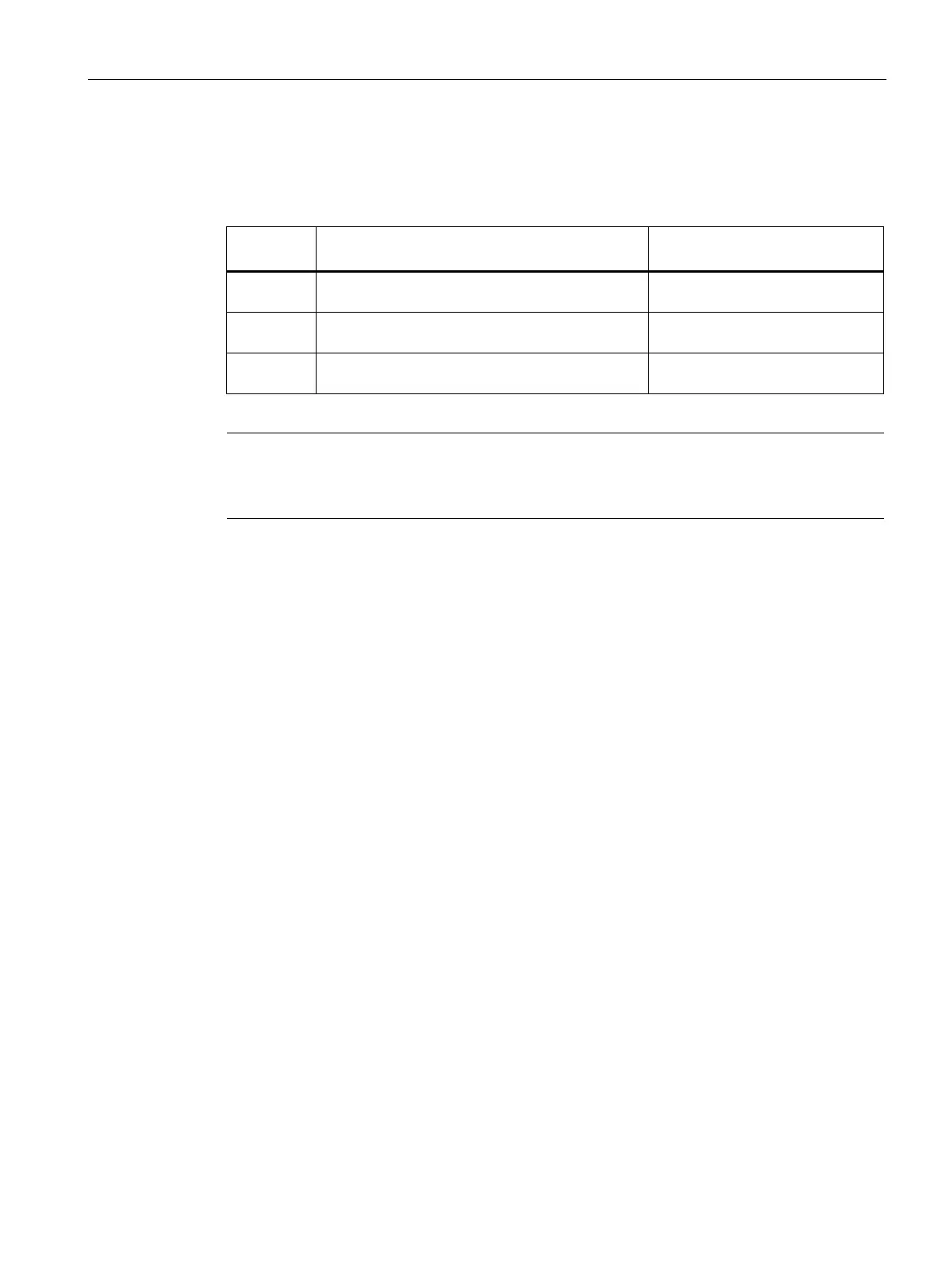

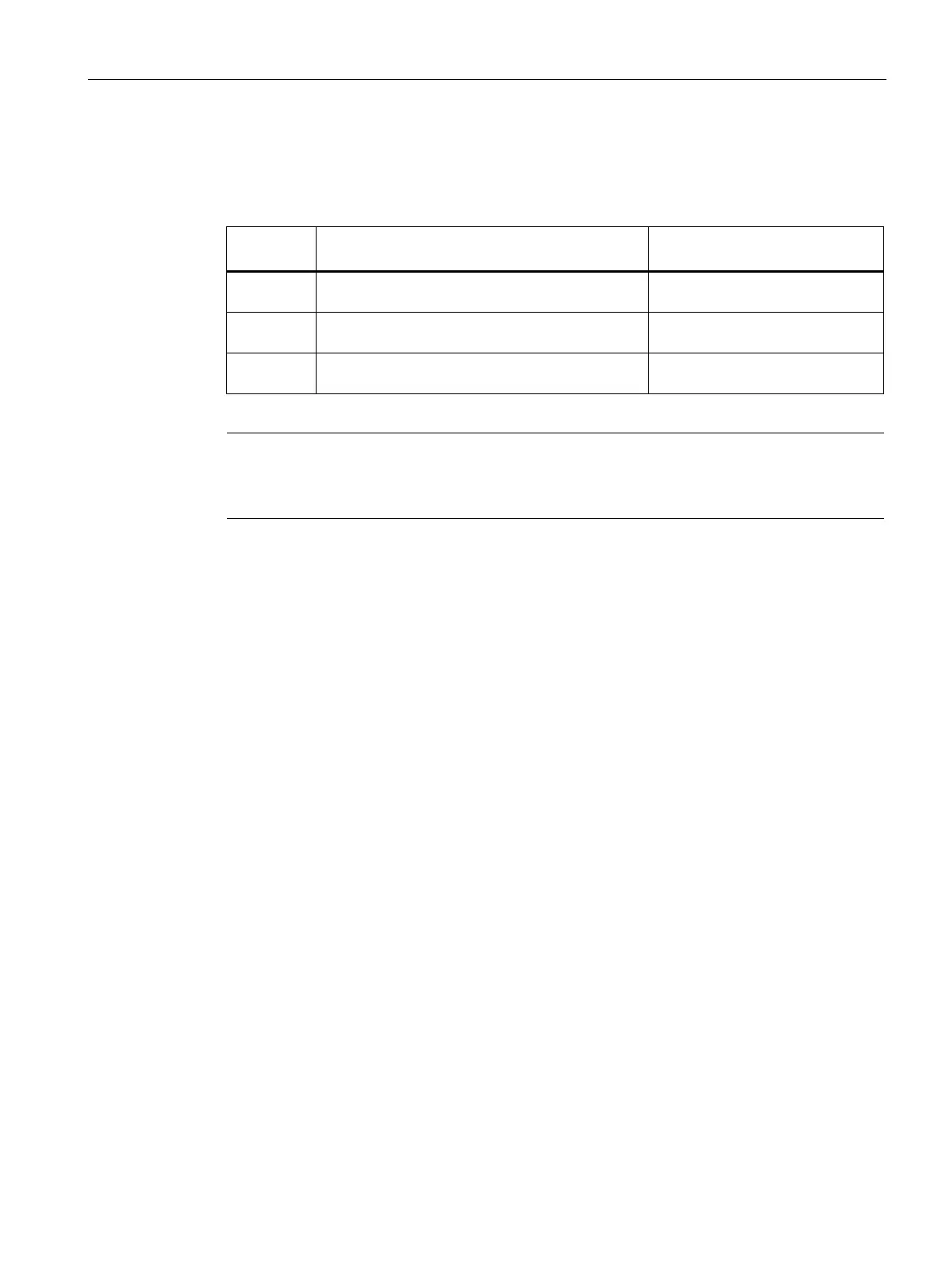

Threaded hole at the rotor DE (face side)

Tensioning elements in the inner

diameter of the rotor

150 12 x M12, 24 mm deep, pitch circle diameter ∅

Inside diameter, 153 mm H7

200 12 x M12, 24 mm deep, pitch circle diameter ∅

Inside diameter, 153 mm H7

280 24 x M16, 34 mm deep, pitch circle diameter ∅

Inside diameter 250 mm H7

Note

Maintain the permissible clamping ranges.

n the permissible surface pressure.

Preconditions for smooth, vibration-free operation

Preconditions for smooth, vibration-free operation include:

● A stable foundation design

● Precise motor alignment.

Comply with the following mounting instructions:

● Ensure a stiff mounting design, especially when flange mounting high-speed motors. As a

consequence, you shift the natural mounting frequency above the maximum rotational

frequency.

● Align the motors using shims under the mounting feet. This avoids deforming/distorting

the motor. Use the fewest possible shims.

● To securely fix the motor and transfer the drive torque, use bolts with property class 8.8.

Loading...

Loading...