8

Tool Offsets 04.00

8.5 Activate 3D tool offsets

8

840D

NCU 572

NCU 573

840Di

Siemens AG 2000. All rights reserved

8-280

SINUMERIK 840D/840Di/810D/FM-NC Programming Guide Advanced (PGA)

−

04.00 Edition

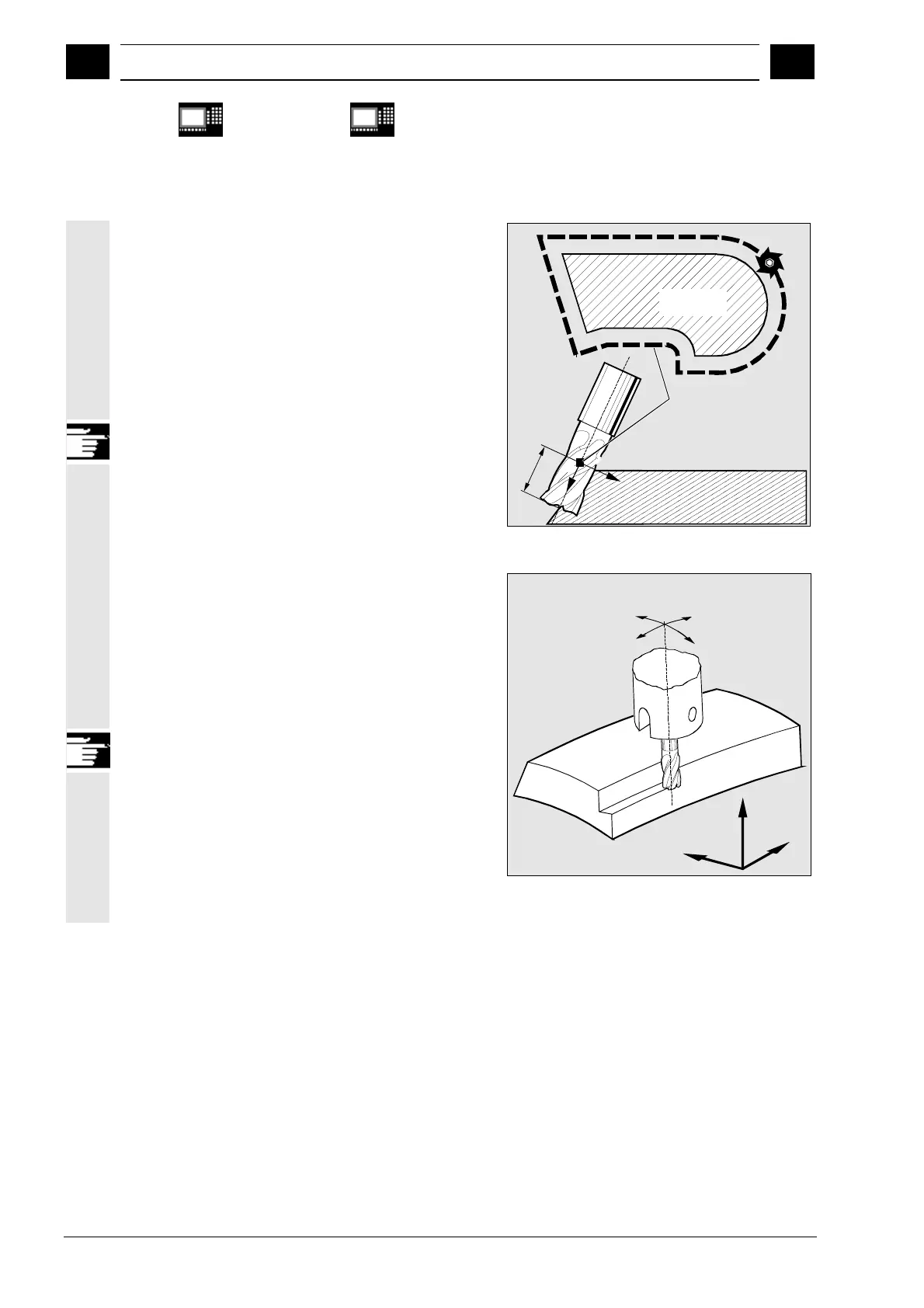

Difference between 2 1/2D and 3D tool radius

compensation

In 3D tool radius compensation tool orientation can

be changed.

2 1/2D tool radius compensation assumes the use of

a tool with constant orientation.

3D tool radius compensation is also called 5D tool

radius compensation, because in this case 5

degrees of freedom are available for the orientation

of the tool in space.

ISD

L

R

Path of tool center point

equidistant from contour

Workpiece

contour

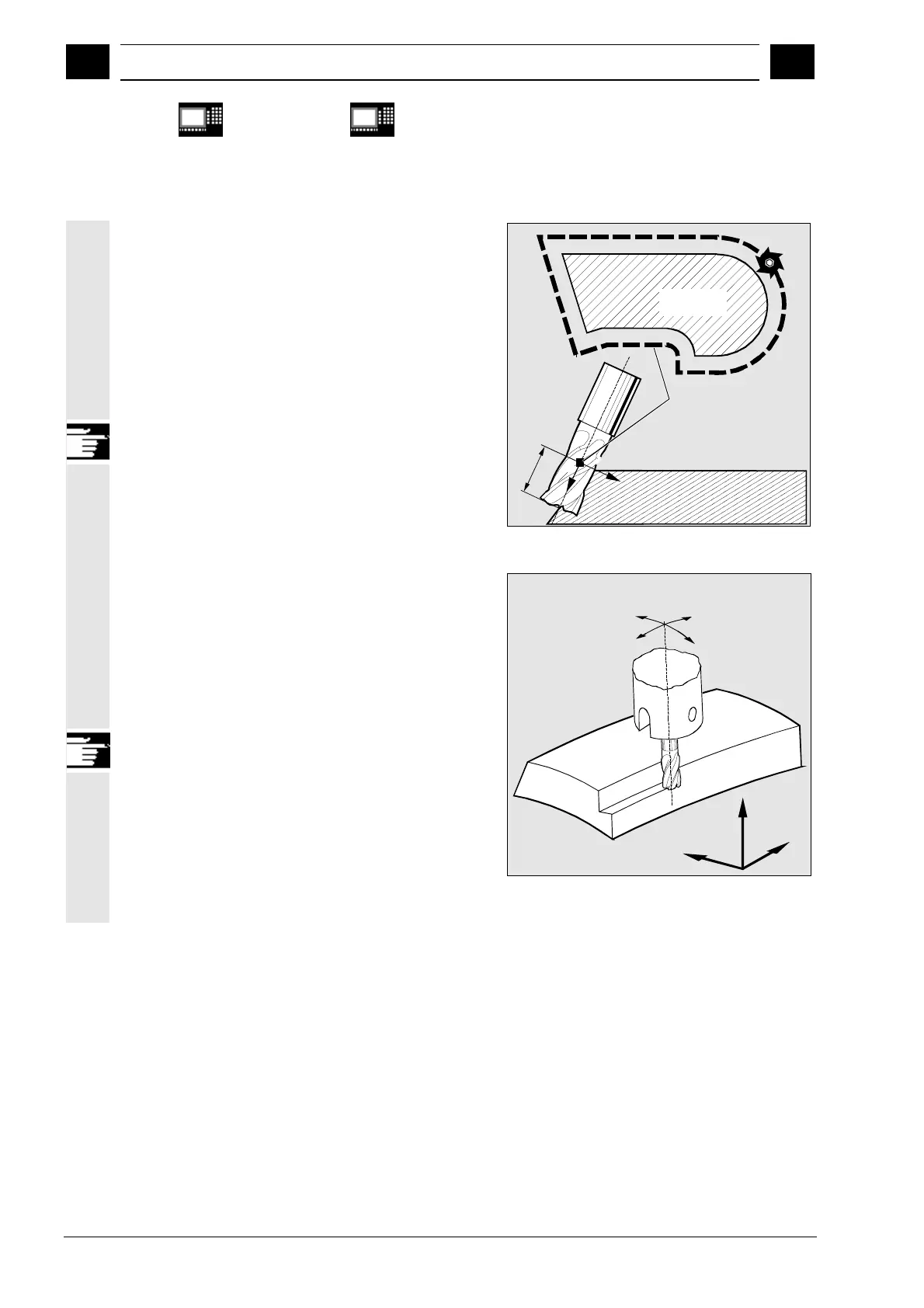

Circumferential milling

The type of milling used here is implemented by

defining a path (guide line) and the corresponding

orientation. In this type of machining, the shape of

the tool on the path is not relevant. The only deciding

factor is the radius at the tool insertion point.

The 3D TRC function is limited to cylindrical tools.

A

B

Z

Y

X

Circumferential milling

Loading...

Loading...