7

Transformations 08.97

7.3 C

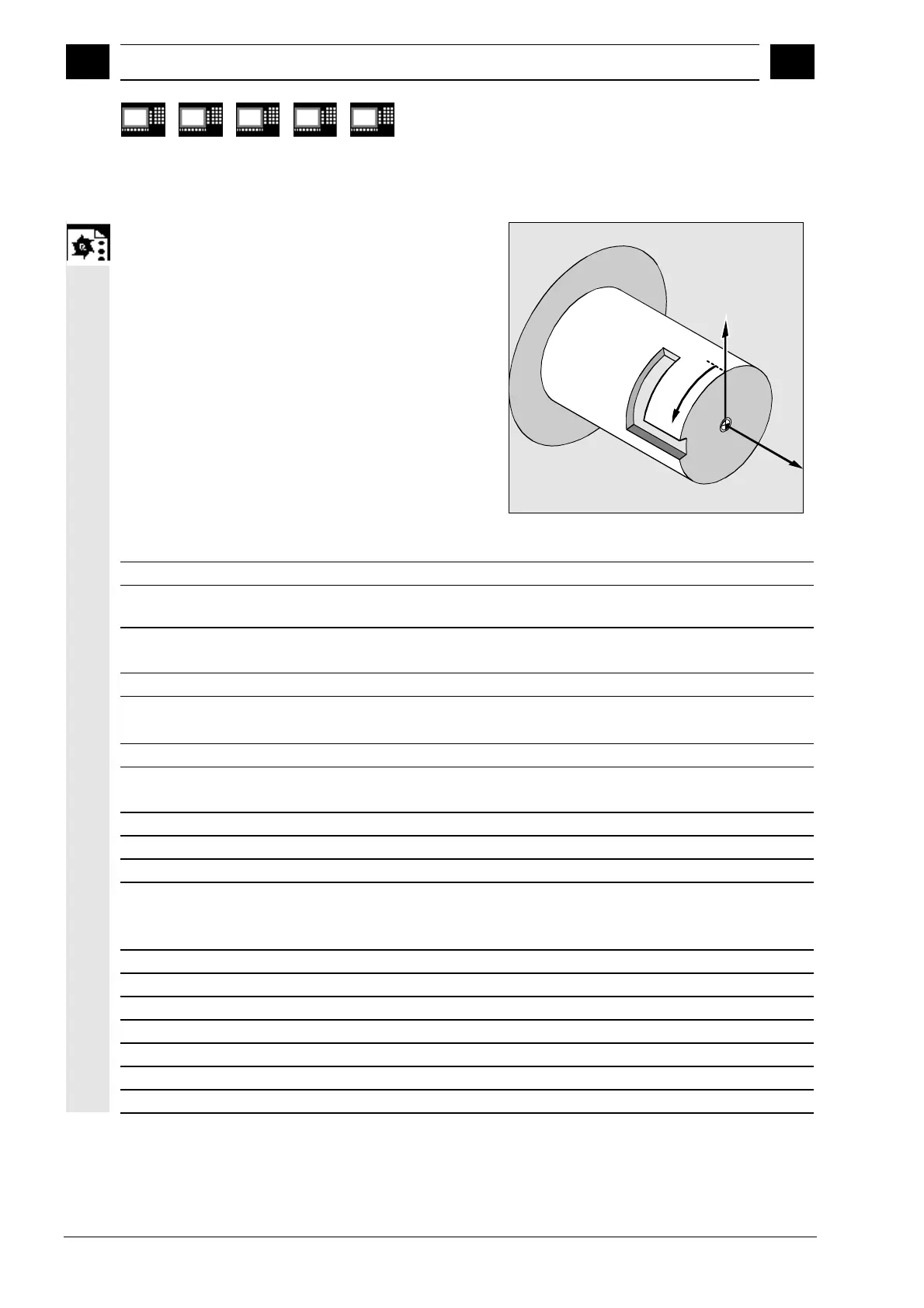

linder surface transformation: TRACYL

7

840D

NCU 571

840D

NCU 572

NCU 573

FM-NC

810D

840Di

Siemens AG 2000. All rights reserved

7-246

SINUMERIK 840D/840Di/810D/FM-NC Programming Guide Advanced (PGA)

−

04.00 Edition

Programming example

X

Y

Z

N10 T1 D1 G54 G90 F5000 G94

Tool selection, clamping compensation

N20 SPOS=0

N30 G0 X25 Y0 Z105 CC=200

Approach reference point

N40 TRACYL (40)

Switch on cylinder surface curve

transformation

N50 G19

Select plane

Producing a hook-shaped groove:

N60 G1 X20

Infeed tool to base of groove

N70 OFFN=12

Set groove side distance 12 mm relative

to the groove center line

N80 G1 Z100 G42

Approach the right groove side

N90 G1 Z50

Groove section parallel to cylinder axis

N100 G1 Y10

Groove section parallel to circumference

N110 OFFN=4 G42

Approach left groove side; set groove

side distance 4 mm from to the groove

center line

N120 G1 Y70

Groove section parallel to circumference

N130 G1 Z100

Groove section parallel to cylinder axis

N140 G1 Z105 G40

Retract from the side of the groove

N150 G1 X25

Retract

N160 TRAFOOF

N170 G0 X25 Y0 Z105 CC=200

Approach reference point

N180 M30

Loading...

Loading...