13

Additional Functions 12.98

13.3 S

nchronized s

indle

13

840D

NCU 571

840D

NCU 572

NCU 573

840Di

Siemens AG 2000. All rights reserved

13-432

SINUMERIK 840D/840Di/810D/FM-NC Programming Guide Advanced (PGA) – 04.00 Edition

Function

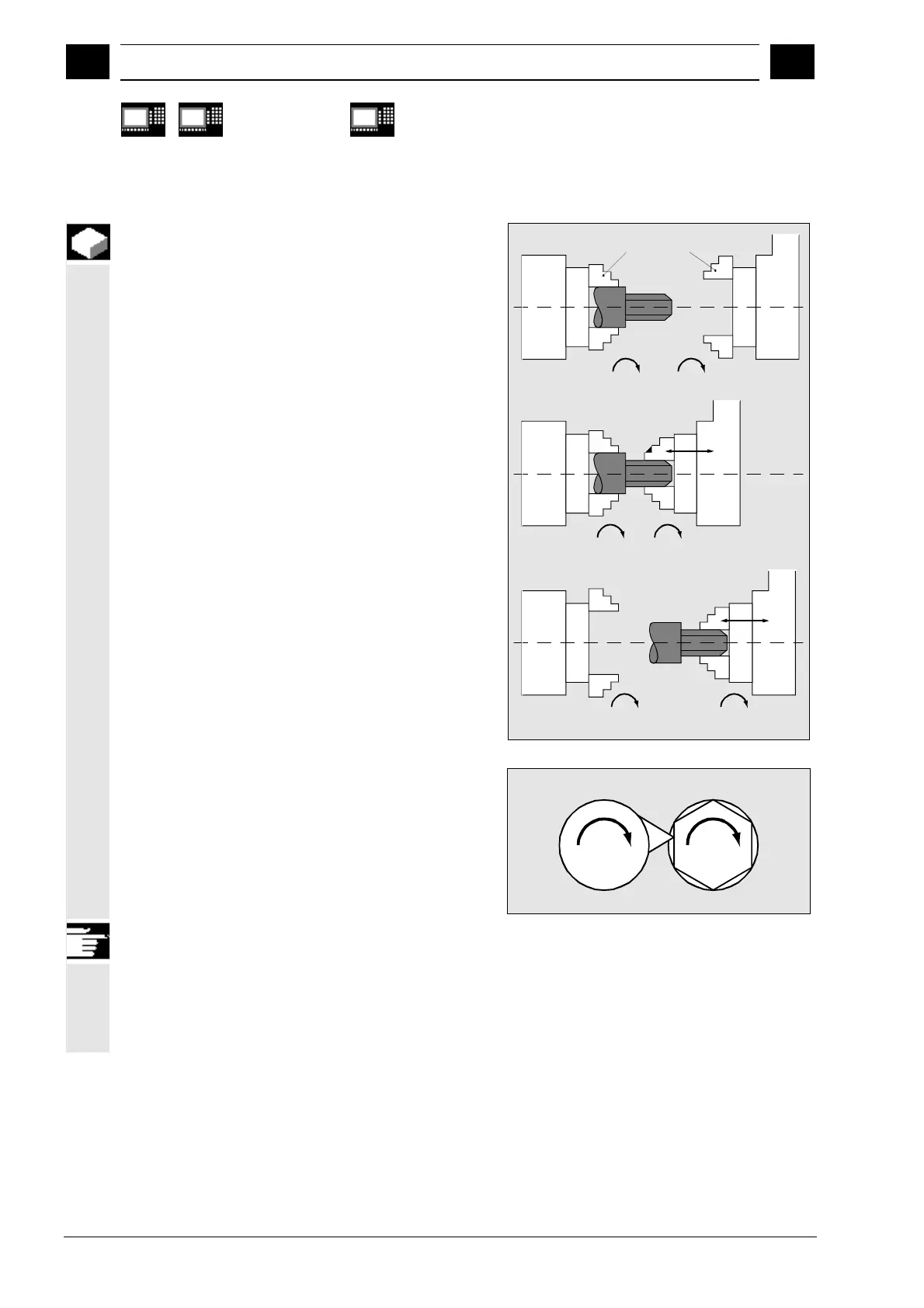

In synchronized mode, there is a leading spindle

(LS) and a following spindle (FS). They are referred

to as the

synchronized spindle pair

.

The following

spindle follows the movements of the leading spindle

when the coupling is active (synchronized mode) in

accordance with the functional relationship specified

in the parameters.

This function enables turning machines to perform

workpiece transfer from spindle 1 to spindle 2 on-

the-fly, e.g. for final machining. This avoids

downtime caused, for example, by rechucking.

The transfer of the workpiece can be performed

with:

•

Speed synchronism (n

FS

= n

LS

)

•

Position synchronism (

ϕ

FS

=

ϕ

LS

)

•

Position synchronism with angular offset

(

ϕ

FS

=

ϕ

LS

+

∆ϕ

)

n2

n2

n1

n1

n2n1

Chuck

Spindle 1

Spindle 2

Spindle 1

Spindle 2

Spindle 1 Spindle 2

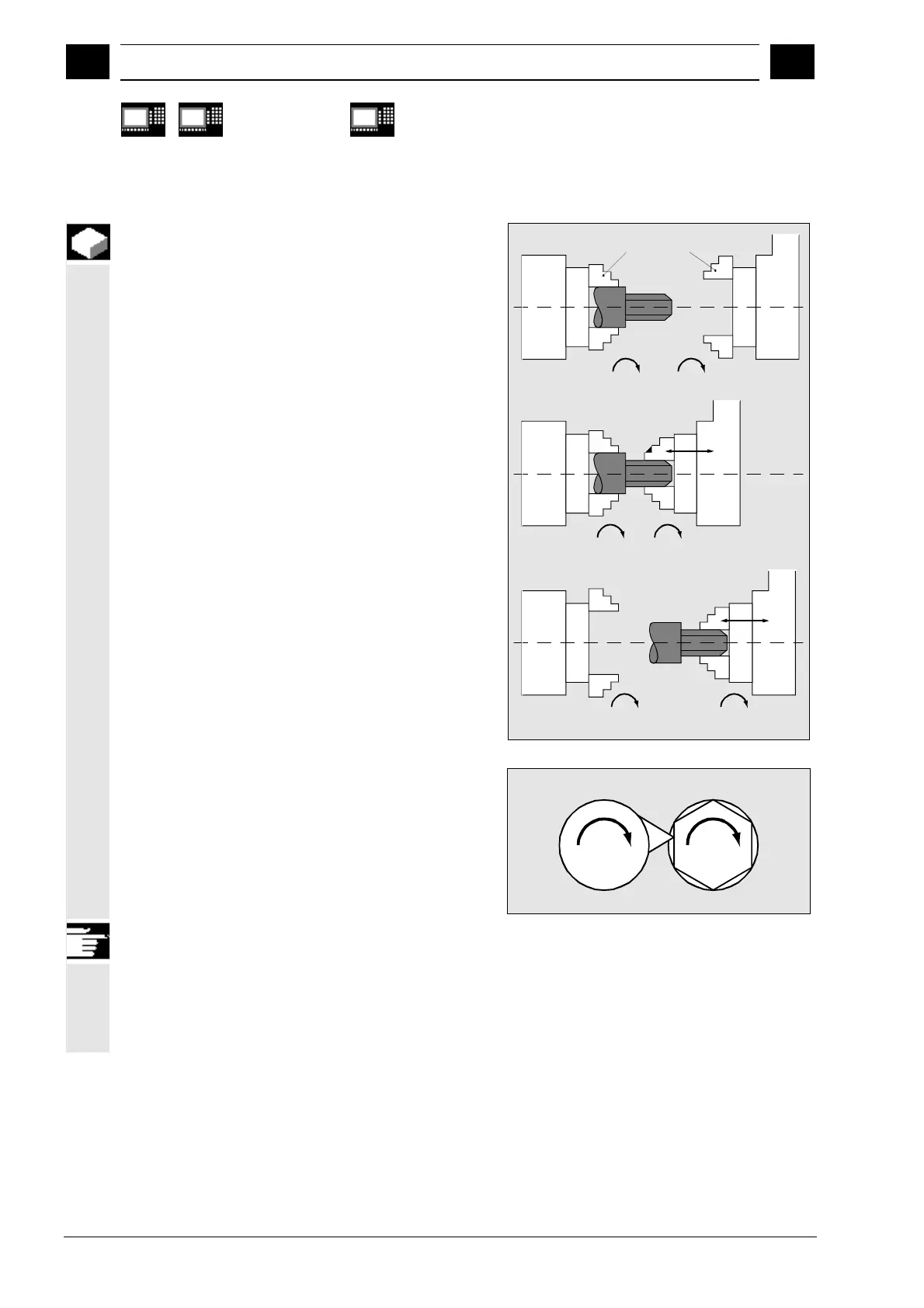

A speed ratio k

Ü

can also be specified between the

main spindle and a "tool spindle" for multi-edge

machining (polygon turning).

n1n2

The synchronized spindle pair can be defined

permanently for each machine with channel-specific

machine data or defined by the user in the CNC part

program.

Up to two synchronized spindle pairs can be

operated simultaneously on each NC channel.

Loading...

Loading...