Connecting the positioner

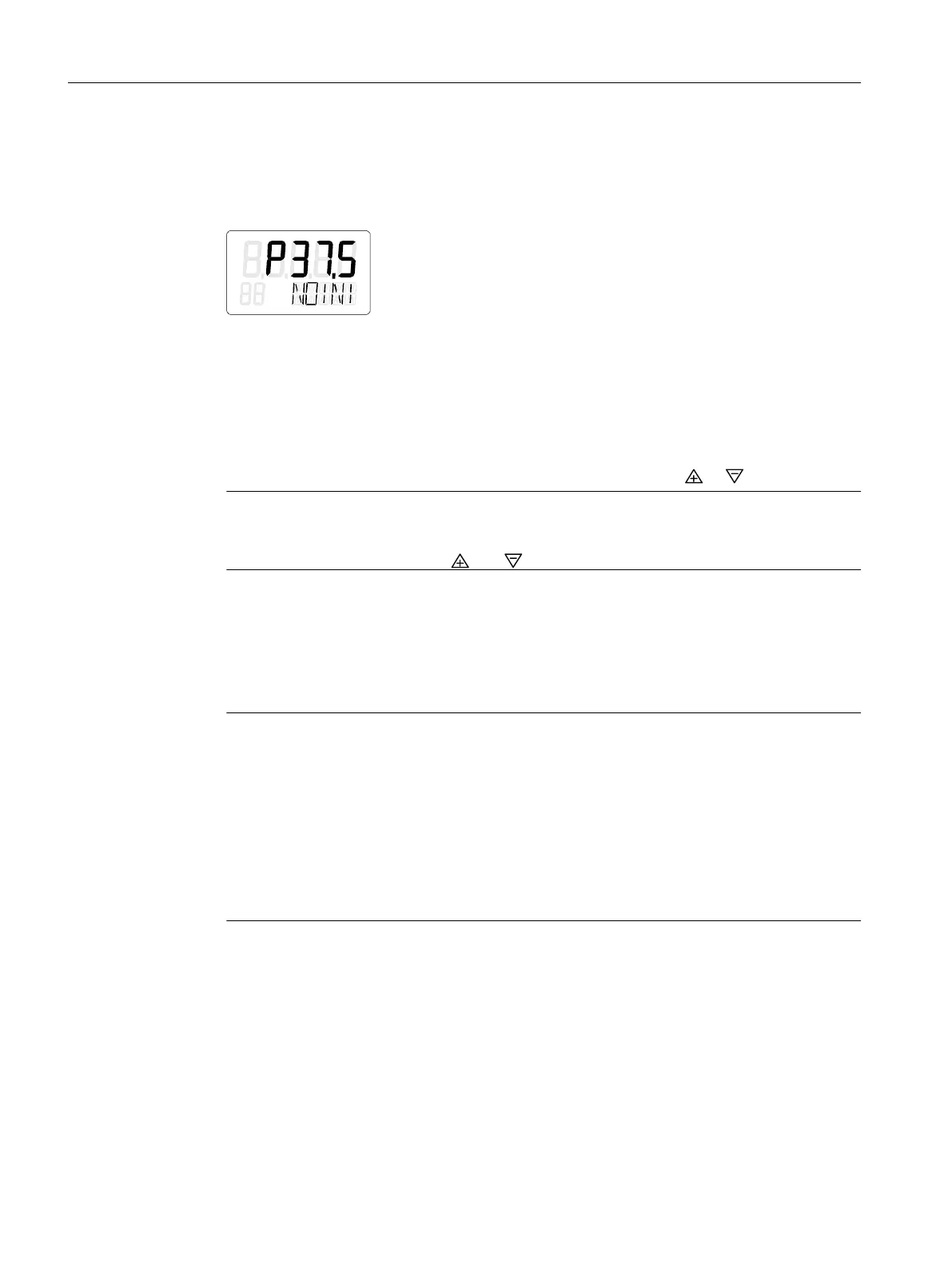

1. Connect a suitable power supply. The positioner is now in "P manual mode". The current

potentiometer voltage (P) in percent is shown in the upper line of the display, e.g.: 'P37.5',

and 'NOINI' flashes in the bottom line:

2. Connect the actuator and the positioner to the pneumatic lines.

3. Supplying the positioner with supply pressure PZ.

Setting the actuator

1. Check whether the mechanical unit can be moved freely in the entire travel range. Move the

actuator to the respective end position for this purpose using the or button.

Note

End position

By simultaneously pressing the and buttons, you reach the end position faster.

2. Now move the actuator to the horizontal position of the lever.

3. A value between 'P48.0' and 'P52.0' is shown on the display.

4. If a value beyond this value range is shown on the display, you must move the friction clutch.

Move the friction clutch until a value between 'P48.0' and 'P52.0' is reached. The closer this

value is to 'P50.0', the more accurately the positioner determines the stroke travel.

Note

For device versions with flameproof enclosure

The inner friction clutch is fixed. Therefore, only move the outer friction clutch. This also

applies when using an internal NCS module.

The following applies to device versions without flameproof enclosure with internal NCS

module 6DR4004-5L.:

The inner friction clutch has no function. This means you should only adjust the adjustment

wheel of the magnet clamp; see section "Internal NCS module (iNCS) 6DR4004-5L / -5LE

(Page 68)". Condition: The '1.YFCT' type of actuator (Page 143) parameter is set.

See also

Mounting to linear actuator (Page 40)

Opening the device version with "flameproof enclosure" (Page 55)

Commissioning

7.10 Commissioning linear actuators

SIPART PS2 with 4 to 20 mA/HART

118 Operating Instructions, 11/2019, A5E00074631-AE

Loading...

Loading...