NOTICE

Incorrect mounting

The device can be damaged, destroyed, or its functionality impaired through improper

mounting.

● Before installing ensure there is no visible damage to the device.

● Make sure that process connectors are clean, and suitable gaskets and glands are used.

● Mount the device using suitable tools. Refer to the information in Technical data

(Page 239).

4.2 Mounting to linear actuator

Requirements

There are linear actuators for standard mounting in accordance with IEC 60534 and for

integrated mounting. Use the reduced mounting kit 6DR4004-8VK for actuators with integrated

mounting. Integrated mounting is not possible with flameproof stainless steel enclosure

(6DR5..6).

This section describes how to connect the positioner to the linear actuator according to

IEC 60534. Depending on the stroke height, you will need the following mounting kit:

● 3 to 35 mm mounting kit 6DR4004-8V

● 35 to 130 mm mounting kit 6DR4004-8V and additional 6DR4004-8L

See also

Construction (Page 240)

Procedure

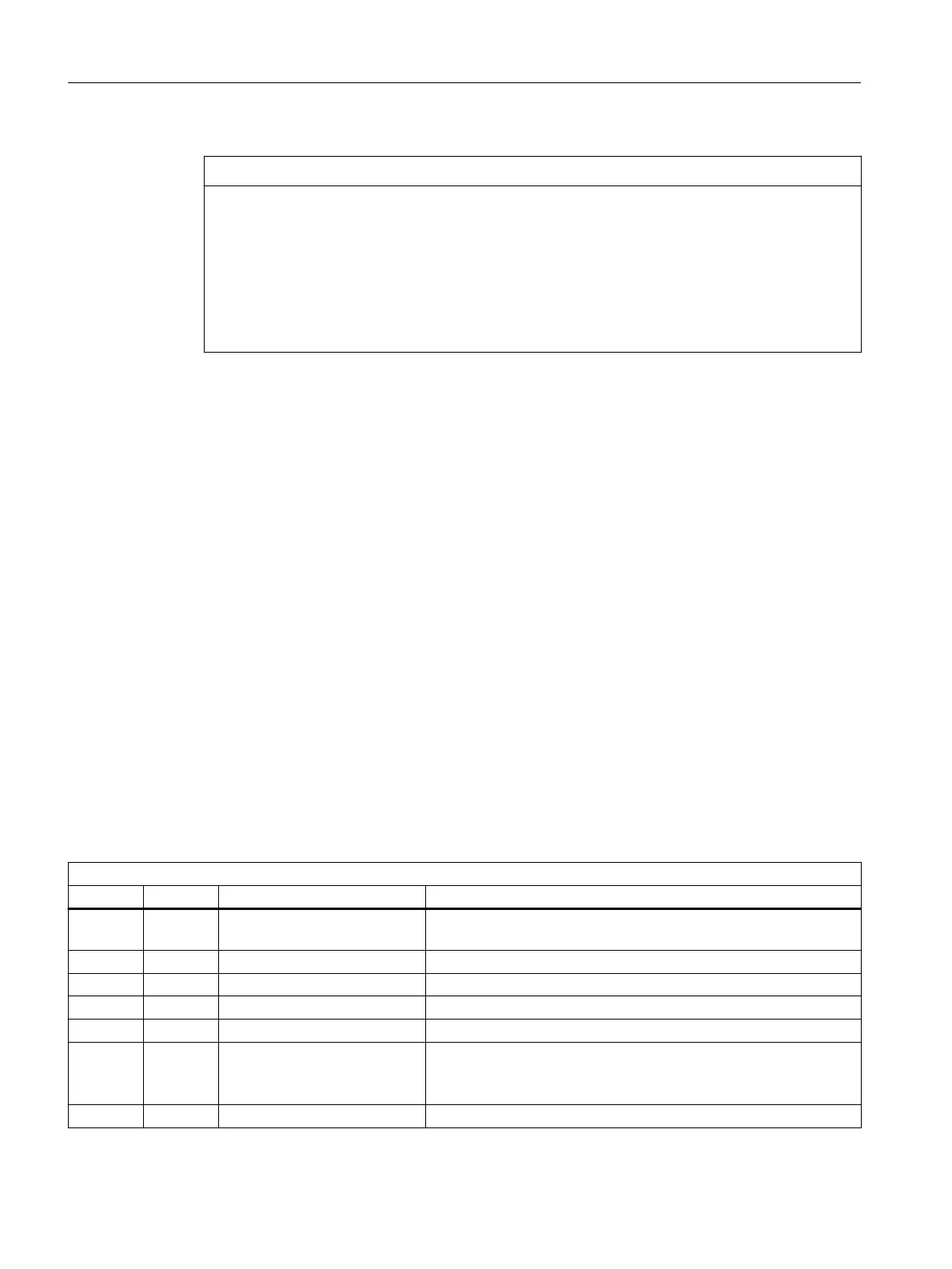

"Linear actuator IEC 60534 (3 to 35 mm)" mounting kit 6DR4004-8V and 6DR4004-8L

Sr. no.

*)

Quantity Name Note

① 1 NAMUR mounting bracket

IEC 60534

Standardized connection point for mount with fin, column or plane

surface

② 1 Pick-up bracket Guides the pulley with the carrier pin and rotates the lever arm.

③ 2 Clamping piece Installs the pick-up bracket on the actuator spindle

④ 1 Carrier pin Installation with pulley ⑤ on lever ⑥

⑤ 1 Pulley Installation with carrier pin ④ on lever ⑥

⑥ 1 Lever For the range of stroke from 3 mm to 35 mm

The lever 6DR4004–8L is additionally required for ranges of stroke

> 35 mm to 130 mm (not included in the scope of delivery).

⑦ 2 U–bolts Only for actuators with columns

Installing/mounting

4.2 Mounting to linear actuator

SIPART PS2 with 4 to 20 mA/HART

40 Operating Instructions, 11/2019, A5E00074631-AE

Loading...

Loading...