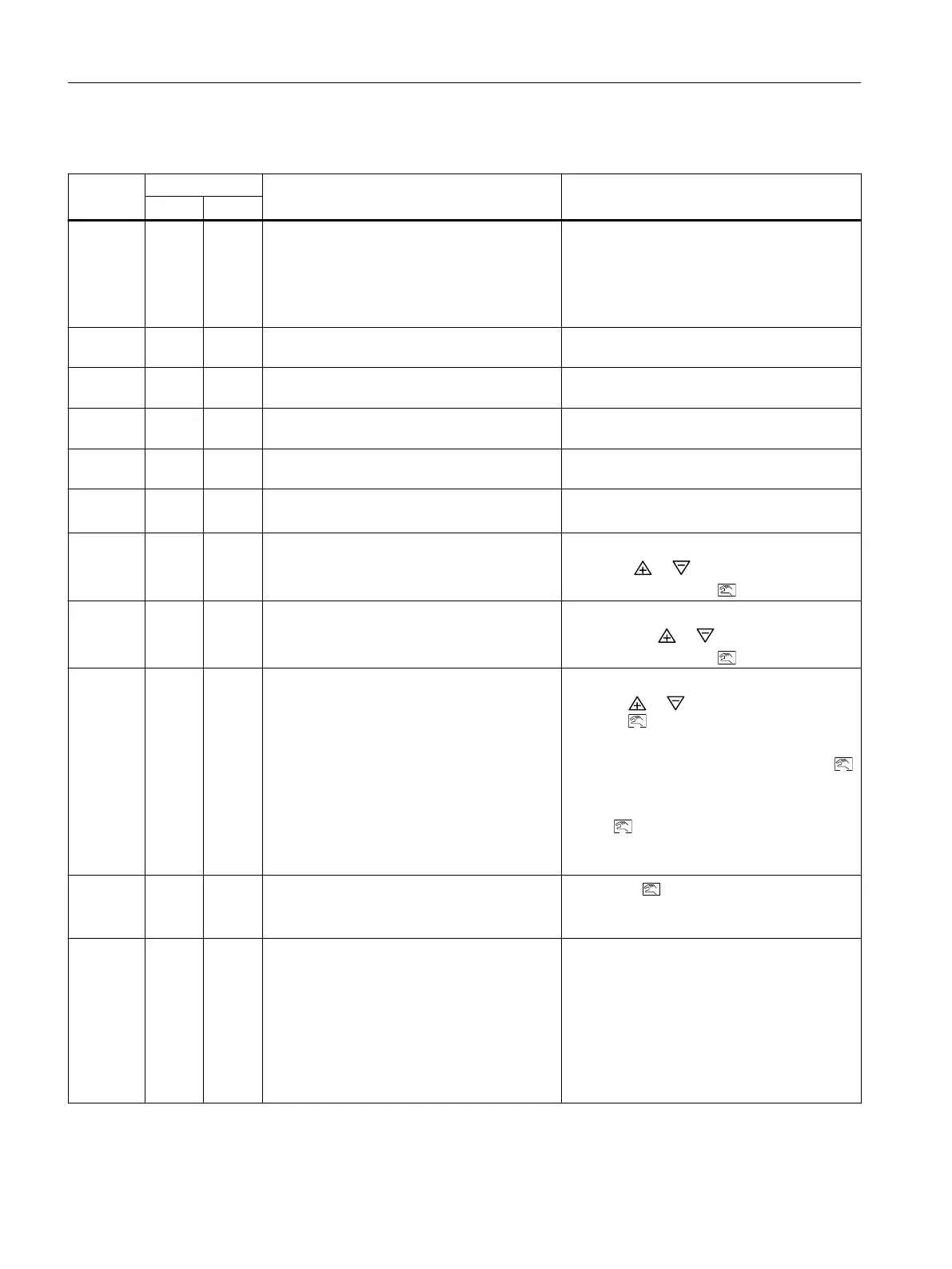

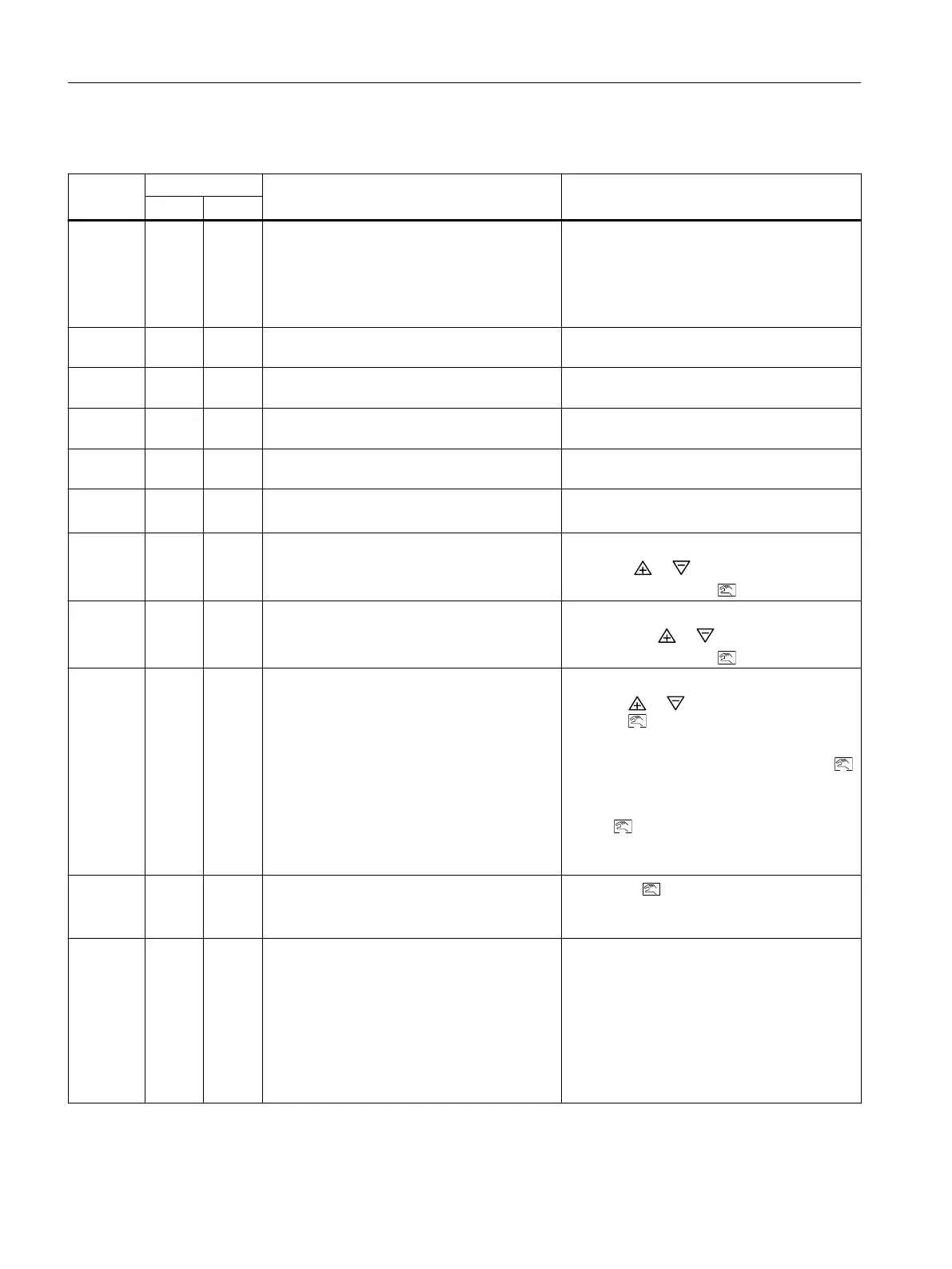

Messages during initialization

Message Line Meaning/cause Measure

Up Down

P--- X Measuring range was exceeded, the potenti‐

ometer is in the inactive zone, the transmis‐

sion ratio selectors or the effective lever arm

are not adjusted as per the actuator travel

● Switch the transmission ratio selector to

90°, especially in the case of part-turn ac‐

tuators.

● Adjust the effective lever length of linear

actuators as per the measuring range.

RUN 1 X Initialization was started, part 1 is active (the

direction of action is determined)

● Wait.

RUN 2 X Initialization part 2 is active (actuator travel

check and determination of stops)

● Wait.

RUN 3 X Initialization part 3 is active (determination

and display of travel times)

● Wait.

RUN 4 X Initialization part 4 is active (determination of

the minimum controller increment length)

● Wait.

RUN 5 X Initialization part 5 is active (optimization of

the transient response)

● Wait until "FINSH" is displayed. Initializa‐

tion was completed successfully.

YEND1 X The first position of the stop can be approach‐

ed only in case of a manual initialization

1. Approach first position of the stop with the

button or .

2. Acknowledge using button.

YEND2 X The second position of the stop can be ap‐

proached only in case of a manual initialization

1. Approach second position of the stop with

the button or .

2. Acknowledge using button.

RANGE X The position of the stop or the measuring

span is beyond the permissible measuring

range only in case of a manual initialization

● Approach a different position of the stop

using or button and acknowledge

using button.

● Move the friction clutch until "ok" is dis‐

played, and then acknowledge with the

button.

● Terminate the initialization process using

the button, switch to the P-manual

mode, and correct the actuator travel and

the position displacement sensor.

ok x The permissible measuring range of end po‐

sitions is achieved only in case of a manual

initialization

● Use the button to acknowledge; the re‐

maining steps ("RUN 1" to "FINSH") run

automatically.

RUN 1 /

ERROR

X Error in "RUN 1", no movement e.g. due to the

lack of compressed air

Possible causes:

● Insufficient supply of compressed air.

● Restrictor(s) blocked.

● Actuator does not move freely.

Measures:

1. Eliminate possible causes.

2. Restart initialization.

Diagnostics and troubleshooting

11.1 Output of system messages in the display

SIPART PS2 with 4 to 20 mA/HART

208 Operating Instructions, 11/2019, A5E00074631-AE

Loading...

Loading...