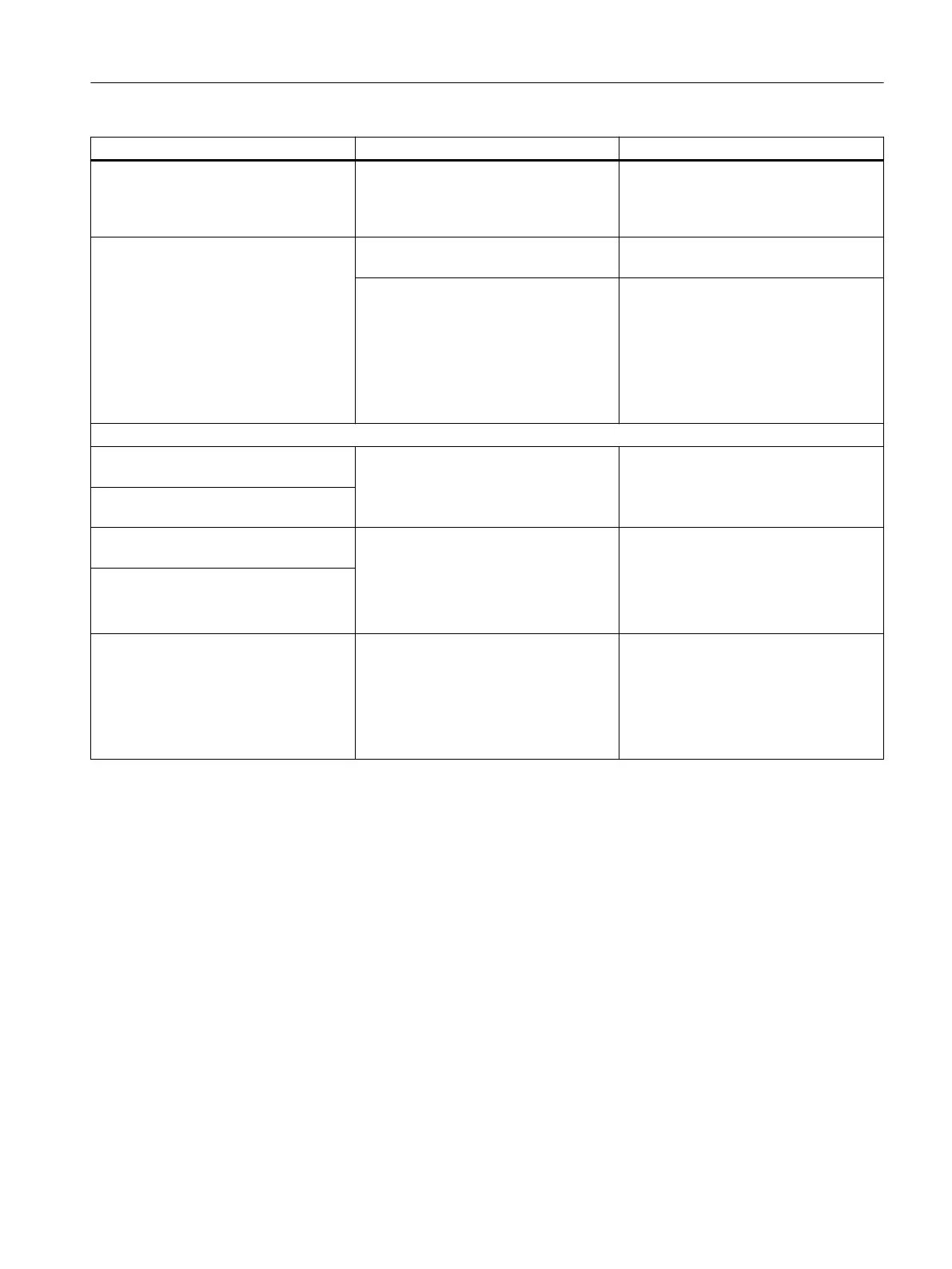

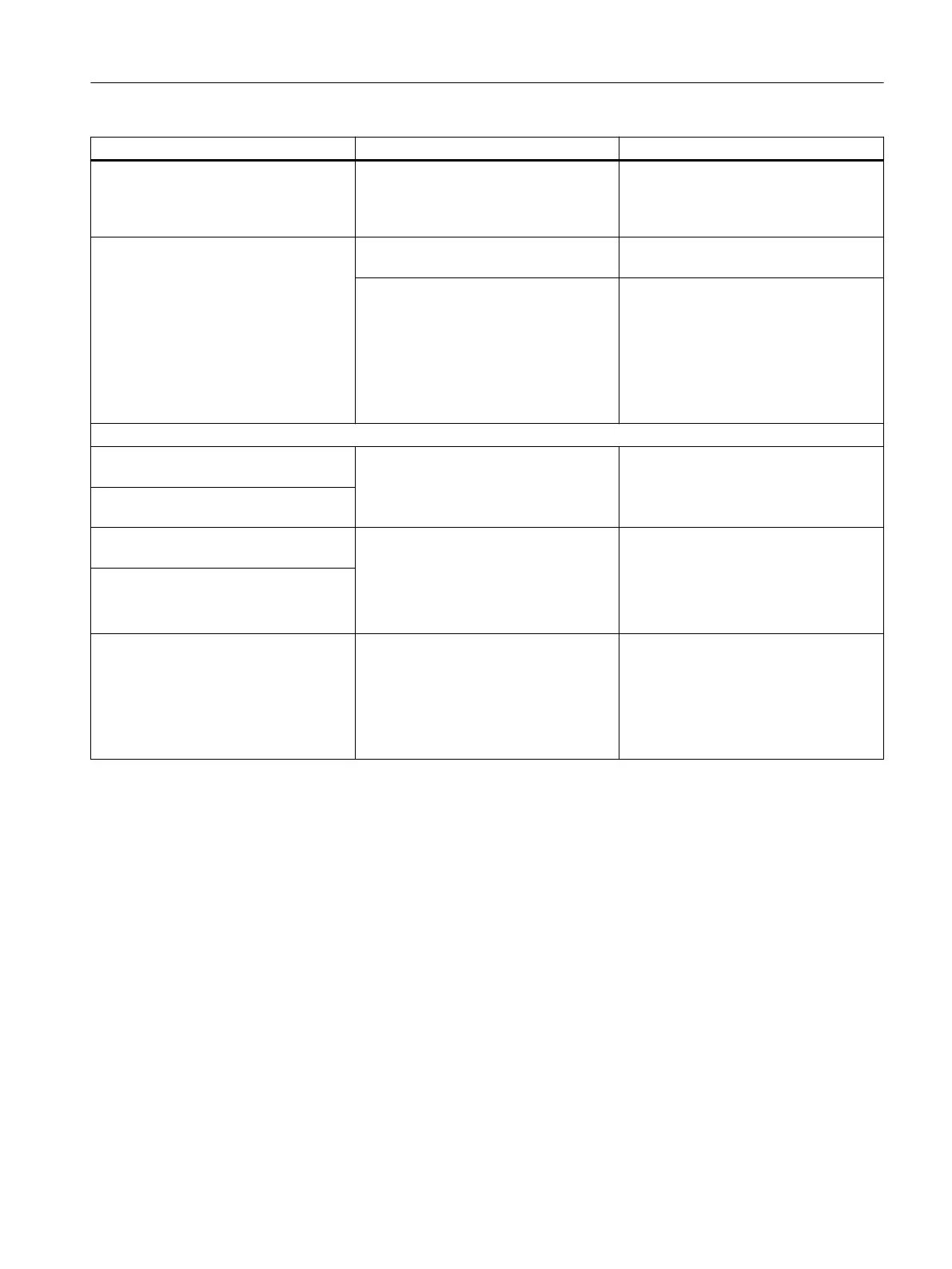

Fault profile (symptoms) Possible cause(s) Remedy

Zero point displaces sporadically (> 3%). Impact or shock loads result in acceler‐

ations so high that the friction clutch

moves, e.g. due to "vapor shocks" in va‐

por lines.

● Rectify the causes for shock loads.

● Re-initialize the positioner.

The device function has completely

failed: No representation on the display

either.

Electrical auxiliary power is not ade‐

quate.

● Check the electrical auxiliary power.

In case of very high continuous loads

due to vibrations (oscillations):

● Screws of the electrical connecting

terminals may be loosened.

● Electrical connecting terminals

and/or electronic components may

be knocked out.

● Tighten the screws firmly and secure

using sealing wax.

● Repair

● For prevention: Install the positioner

on damping pads.

Pressure sensor module

With diagnostic value "60.PZ

(Page 228)", display shows "99999".

● Pressure sensor module defective ● Replace the pressure sensor mod‐

ule (Page 203)

Display shows fault message "17

(Page 234)".

Display shows fault message "18

(Page 234)".

● Supply pressure undershoots the

lower limit (U2.PZLIM (Page 188)).

● Device is set to "Hold position",

when (U4.PZ_FR) "HOLd" is as‐

signed as error response.

● Increase the supply pressure until

the limit (U2.PZLIM) incl. hysteresis

(U3.PZHYS) is exceeded.

Display shows "HOLd".

Display shows fault message "19

(Page 234)".

● Supply pressure outside the specifi‐

cation

● Increase the supply pressure until

the limit (U2.PZLIM) incl. hysteresis

(U3.PZHYS) is exceeded.

● Lower the supply pressure until the

limit (U2.PZLIM) incl. hysteresis

(U3.PZHYS) is undershot.

Diagnostics and troubleshooting

11.4 Fault and remedy

SIPART PS2 with 4 to 20 mA/HART

Operating Instructions, 11/2019, A5E00074631-AE 237

Loading...

Loading...