5-25

R

Initiation

5.5 Welding parameters

IMPORTANT

☞ The set welding parameters influence the reproducibility and

quality of the welding results to a large extent. The parameters

depend on the size of the studs and the material properties. The

values indicated in the table are standard values which are

exclusively valid for studs supplied by SOYER. They may vary

depending on the type of workpiece, the workpiece thickness, the

surface condition and on environmental conditions (e.g. low

outdoor temperatures). The settings of the welding pistol or

welding head also influence the welding parameters (if e.g. the lift

is increased, normally the charging voltage has to be increased

too).

Random samples should be taken during any production process to ensure

constantly good welding results (see DVS Guideline, Part 1, "Quality assurance

of stud welding joints").

The welding parameters were determined with the stud welder BMS-10N and

the stud welding pistol PS-3 using a lift adjustment of about 2.5 mm. A steel

plate with a thickness of 2 mm served as base metal for welding copper-plated

capacitor studs made of ST 37-3, as per DIN 32501.

The values for the charging voltage are possibly somewhat lower when using

the amplified stud welder BMS-10NV.

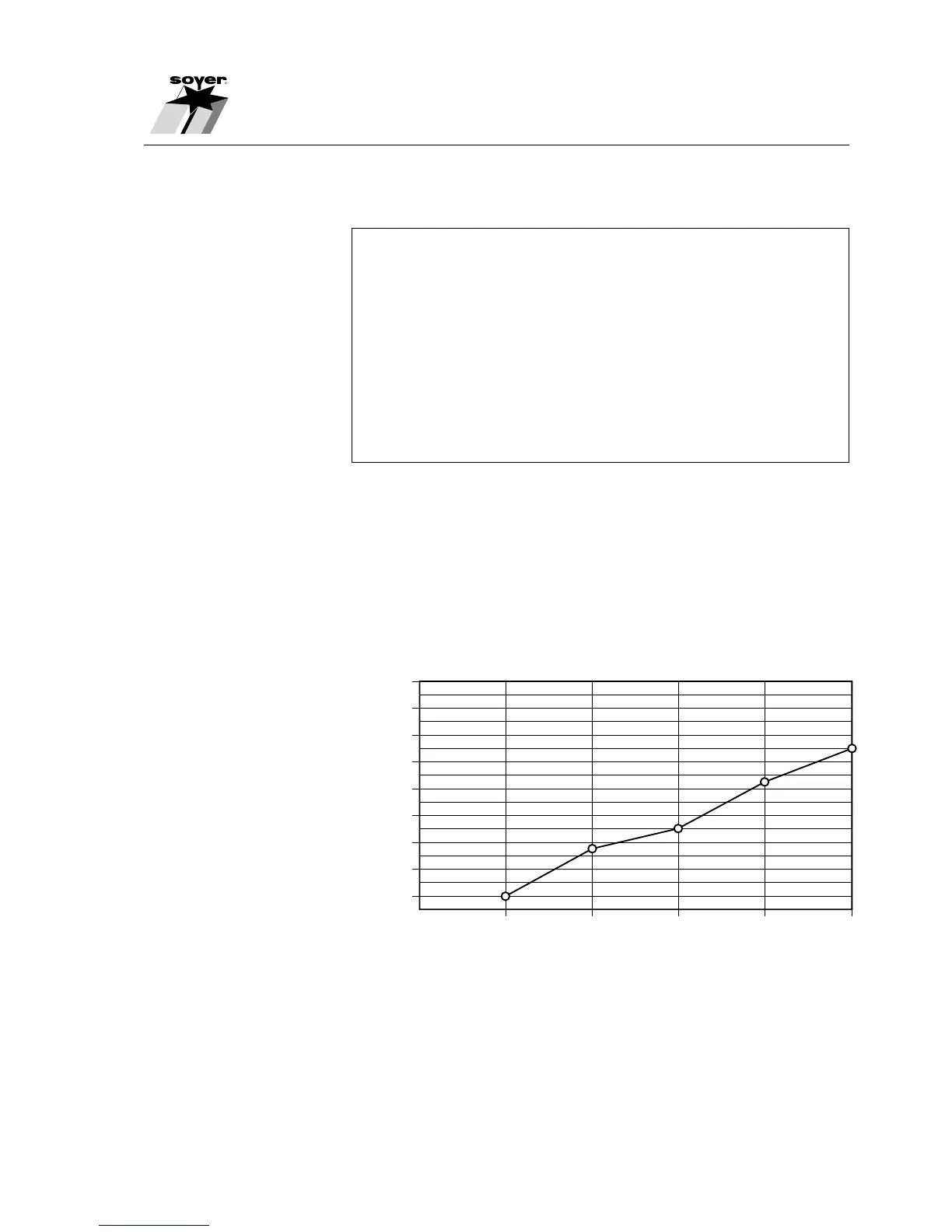

The charging voltages shown

in the diagram on the right are

standard values. They vary

from the stated setting

depending on the material

type, workpiece thickness

and surface condition of the

workpiece.

M3 M4 M5 M6 M8

60

80

100

120

140

160

180

200

220

Stud diameter

Charging voltage (V)

SZ.0048.E

Loading...

Loading...